Manganin high-temperature gas desulfurizer and preparation method thereof

A desulfurizing agent, high temperature technology, used in combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., to achieve high desulfurization accuracy, improve desulfurization accuracy, and reduce equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

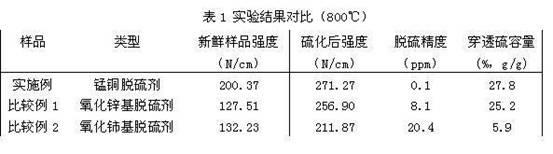

Examples

Embodiment 1

[0025] Use aluminum nitrate nonahydrate as raw material to make a 0.1mol / L solution, then add a certain amount of ammonia water to control the pH value of the solution between 8.8 and 9.7 to obtain a flocculent precipitate, filter the precipitate and then add an appropriate amount of water to stir and dissolve it into Suspension, heat the suspension to 40°C-60°C, add a certain amount of nitric acid to control the acid-aluminum ratio at 0.2-0.3, and then raise the temperature to 80°C-95°C to obtain aluminum sol; weigh 5.74g of copper oxide, 71.68 g of manganese carbonate and 3.87g of pore-forming agent starch were evenly ball-milled, then added 7.74g of sol and stirred evenly, placed in an oven (100°C) to dry for 4-6 hours, then added 15-35% of the mixture's mass of water, and then It is extruded into a cylindrical (Ф1~3mm) desulfurizer body, dried naturally for 24 hours, then placed in an oven at 100°C for 6 hours, and finally placed in a muffle furnace for 13-13 hours at 900°C...

Embodiment 2

[0032] Use aluminum nitrate nonahydrate as raw material to make a 0.1mol / L solution, then add a certain amount of ammonia water to control the pH value of the solution between 8.8 and 9.7 to obtain a flocculent precipitate, filter the precipitate and then add an appropriate amount of water to stir and dissolve it into Suspension, the temperature of the suspension is raised to 40°C-60°C and a certain amount of nitric acid is added to control the acid-aluminum ratio at 0.2-0.3, and then the temperature is raised to 80°C-95°C to obtain aluminum sol, and 57.34g of manganese carbonate, 4.6 g of copper oxide and 3.1g of pore-forming agent carbon black are prepared into powder, the molar ratio of Mn:Cu in the powder is 9:1, and after the powder is evenly ball milled, add 5% of the total mass of manganese carbonate and copper oxide powder respectively , 10%, 15% aluminum sol as the bonding aid to prepare three different powders, and then place them in an oven (100°C) to dry for 4 to 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com