Recovery system and recovery method of low-order coal pyrolysis oil gas

A technology for pyrolysis of oil and gas, recovery system, applied in the removal of gas pollutants, gas dust removal, petroleum industry and other directions, can solve the problems of high dust content, low quality, and difficult purification of VOCs sulfur-containing components, etc. Achieve the effect of less dosage, low cost, and meet the requirements of subsequent pressurized transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

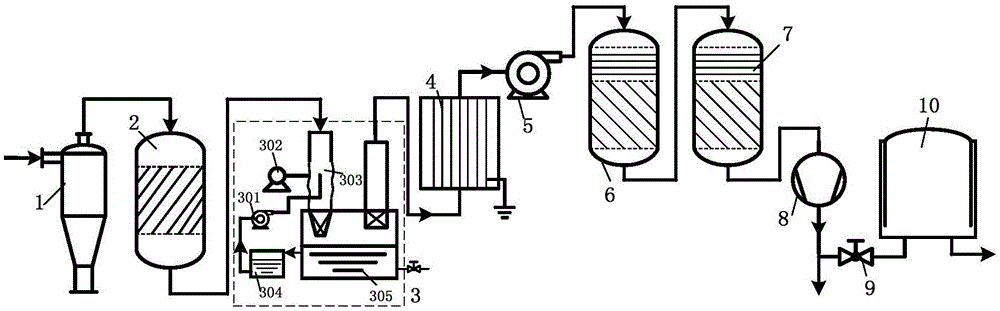

[0043] Example 1: Low-rank coal pyrolysis oil and gas recovery system

[0044] see figure 1 , Low-rank coal pyrolysis oil and gas recovery system, including cyclone dust collector 1, filter dust collector 2, power wave scrubber 3, electric tar catcher 4, fan 5, composite adsorption tower 6, desulfurization tower 7, each equipment through the pipeline Connect sequentially. The gas pipe at the bottom of the desulfurization tower is connected to the pyrolysis gas compressor 8, and the gas outlet pipe of the pyrolysis gas compressor 8 is provided with a throttle valve 9, and the throttled gas finally enters the gas tank 10 through the pipe.

[0045] The filter medium filled in the filter dust collector 2 of this system is pyrolysis semi-coke. The composite adsorption tower 6 is filled with two upper and lower layers of adsorbent. The desulfurization tower 7 is filled with upper and lower layers of desulfurization agent.

[0046] The power wave scrubber 3 includes an ammonia storage t...

Embodiment 2

[0048] The system of Example 1 is adopted, wherein the composite adsorption tower 6 is filled with upper and lower layers of adsorbent, the upper layer is 0.6m sawdust, and the lower layer is 3.5m activated carbon. The desulfurization tower 7 is filled with two upper and lower layers of desulfurizer, the upper layer is 2m pyrolysis semi-coke, and the lower layer is 1.5m iron oxide desulfurizer.

[0049] The method for pyrolysis oil and gas recovery:

[0050] The high temperature (T≈580℃) generated by the pyrolysis of lignite pyrolysis oil and gas overflows from the pyrolysis furnace into the cyclone dust collector to remove the φ≥10μm fine ash in the pyrolysis oil and gas, and then pass the high temperature dust filter to further remove the heat The ash in the oil and gas is decomposed at a temperature of T=315℃. The pyrolysis gas after ash removal enters the power wave scrubber. In the power wave scrubber, the pyrolysis gas and ammonia water transfer mass and heat to remove the ta...

Embodiment 3

[0054] The system of Example 1 is adopted, wherein the composite adsorption tower 6 is filled with upper and lower layers of adsorbent, the upper layer is 0.8m pyrolysis semi-coke, and the lower layer is 3.2m activated carbon). The desulfurization tower 7 is filled with two upper and lower layers of desulfurizer, the upper layer is 2.2m pyrolysis semi-coke, and the lower layer is 1.3m zinc oxide desulfurizer.

[0055] The high temperature (T≈510℃) pyrolysis oil and gas generated by the pyrolysis of long flame coal overflows from the pyrolysis furnace into the cyclone dust collector, and the ash in the pyrolysis oil and gas is removed in the cyclone dust collector and high temperature dust removal filter. The temperature T= At 300℃, the pyrolysis gas after ash removal enters the power wave scrubber. In the power wave scrubber, the pyrolyzed oil and gas exchanges mass and heat with ammonia, removes the tar and water vapor in the pyrolysis oil and gas, and exits the power wave scrubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com