Middle and low temperature coal gas fine desulfurizing agent and preparation method thereof

A desulfurizing agent and gas refining technology, which is applied in the fields of combustible gas purification, combustible gas purification/transformation, petroleum industry, etc. The effect of improving desulfurization accuracy and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

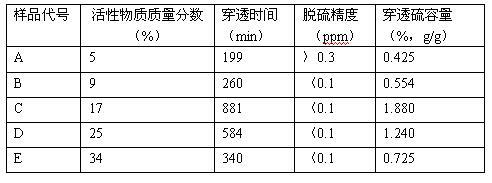

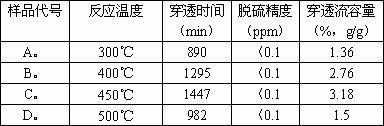

Examples

Embodiment

[0017] The preparation process in this embodiment is as follows:

[0018] Weigh 12.93g of zinc nitrate hexahydrate, measure 1.94ml of manganese nitrate solution with a mass fraction of 49% to 51%, put it in a beaker, add 20ml of distilled water, and stir to dissolve. At this time, the molar ratio of Zn:Mn in the solution is 8:1. 20g γ-Al 2 o 3 Add the carrier to the above solution, seal the mouth of the beaker with plastic wrap, soak it at room temperature for 12 hours, then put it in an oven at 110°C for drying, stir once every 3 minutes during the drying process, and transfer the sample to a muffler after the water is completely evaporated. Calcined in a furnace at 500°C for 3 hours to obtain ZnO-MnO with a molar ratio of Zn:Mn of 8:1 and an active material mass fraction of 17%. 2 / γ-Al 2 o 3 Loaded desulfurizer sample. This sample is the best formulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com