Preparation method for carbon-supported monolayer molybdenum disulfide composite catalyst for low-temperature hydro-conversion of carbonyl sulfide

A single-layer molybdenum disulfide and composite catalyst technology is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., which can solve problems such as high reaction temperature, high energy consumption, and poor desulfurization performance, and achieve The preparation process is simple, the catalytic activity is stable, and the desulfurization precision is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

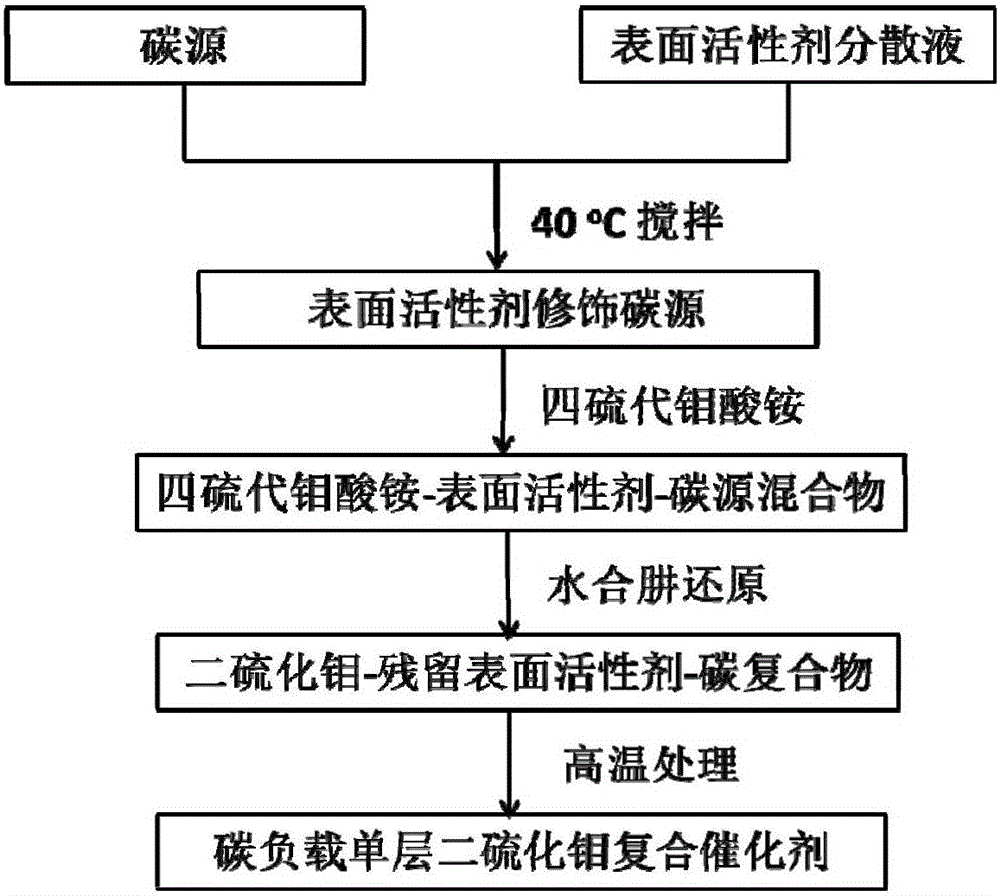

[0046] Such as figure 1 As shown, the present invention "a method for preparing a carbon-supported single-layer molybdenum disulfide composite catalyst for low-temperature hydrogenation conversion of carbonyl sulfide", the specific preparation process is as follows:

[0047] (1) Cetyltrimethylammonium bromide is dispersed in 100mL of deionized water to obtain a 0.01mol / L cetyltrimethylammonium bromide dispersion;

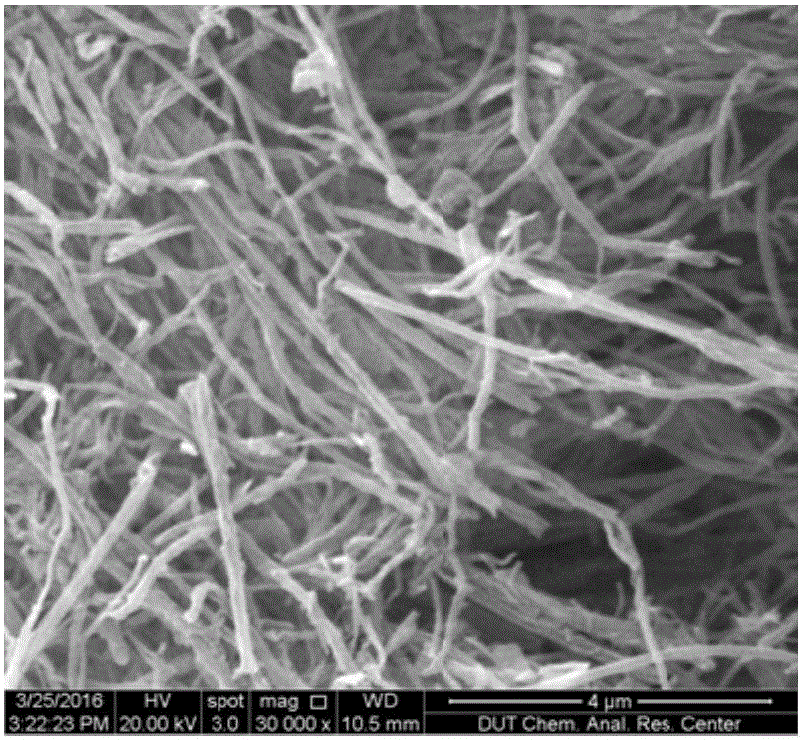

[0048] (2) 200mg of graphene oxide nanobelts were placed into the above-mentioned surfactant solution, and stirred at 40° C. for 12 hours;

[0049] (3) Ammonium tetrathiomolybdate is added in the mixed solution, the mass ratio of ammonium tetrathiomolybdate and graphene oxide nanobelt used is 1:0.83, stir well, add 10mL hydrazine hydrate liquid phase reduction for 6 hours, Suction filtration, washing with water and ethanol, and drying to obtain molybdenum disulfide-residual surfactant-graphene nanoribbon composite material;

[0050] (4) Put the molybdenum disulfid...

specific Embodiment approach

[0053] Compared with the monolayer molybdenum disulfide and graphene nanobelt composite hydrodesulfurization catalyst (SMGR-1) in Example 1, a few-layer molybdenum disulfide and graphene nanobelt composite hydrodesulfurization catalyst, multilayer pure Molybdenum disulfide hydrodesulfurization catalyst and single graphene nanoribbons were used as comparative samples. The specific implementation method: (1) ammonium tetrathiomolybdate is added in the graphene oxide nanobelt, the mass ratio of ammonium tetrathiomolybdate and the graphene oxide nanobelt is 1:0.3, stir evenly, add hydrazine hydrate Liquid phase reduction for 6 hours, suction filtration, washing with water and ethanol, and drying to obtain the molybdenum disulfide-graphene nanoribbon composite material, the molybdenum disulfide-graphene nanoribbon composite material is placed in a tube furnace, protected by nitrogen A high-temperature annealing at 700°C for 2 hours was performed, and after natural cooling down to r...

Embodiment 2

[0058] Such as figure 1 As shown, the present invention "a method for preparing a carbon-supported single-layer molybdenum disulfide composite catalyst for low-temperature hydrogenation conversion of carbonyl sulfide", the specific preparation process is as follows:

[0059] (1) Octadecyltrimethylammonium bromide is dispersed in 100mL deionized water to obtain a 0.1mol / L octadecyltrimethylammonium bromide dispersion;

[0060] (2) 250mg of graphene oxide nanobelts were placed into the above-mentioned surfactant solution, and stirred at 40°C for 24 hours;

[0061] (3) Ammonium tetrathiomolybdate is added in the mixed solution, the mass ratio of ammonium tetrathiomolybdate and graphene oxide nanobelt used is 1:0.36, stir evenly, add 10mL hydrazine hydrate liquid phase reduction for 6 hours, Suction filtration, washing with water and ethanol, and drying to obtain molybdenum disulfide-residual surfactant-graphene nanoribbon composite material;

[0062](4) Place the molybdenum dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com