High airspeed iron desulfurizing agent, preparation method and application of desulfurizing agent

An iron-based desulfurization and space velocity technology, applied in the field of desulfurization, can solve the problems of low utilization rate of additives and inability of desulfurizers to apply high space velocity gas desulfurization, etc., to improve unit combination efficiency, increase effective contact area, and unit treatment The effect of volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

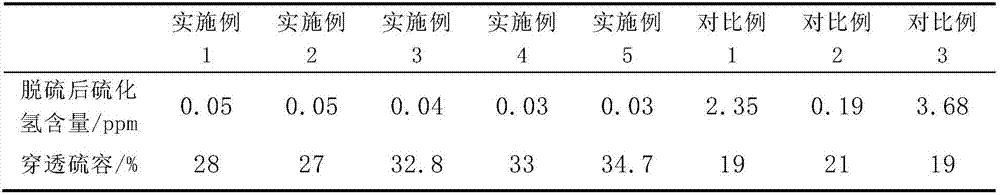

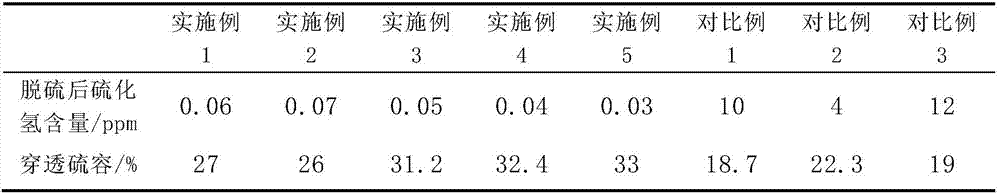

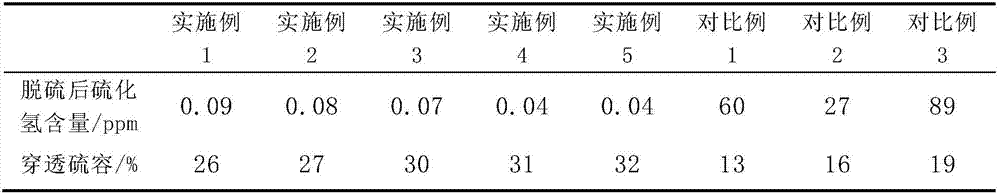

Examples

Embodiment 1

[0041] The high space velocity iron-based desulfurizer provided in this example has a raw material composition comprising: 60 g of high specific surface iron oxyhydroxide, 30 g of active zinc oxide, and 10 g of a 10 wt % aqueous solution of sodium carboxymethyl cellulose.

[0042] It is prepared by the following steps:

[0043] (1) 80 g of high specific surface iron oxyhydroxide, 20 g of active zinc oxide, and 25 g of a 10 wt % aqueous solution of sodium carboxymethylcellulose were mixed for solid-liquid kneading.

[0044](2) Extrude and granulate the mixture obtained in step (1), and then dry it at 50° C. for 1 hour to obtain a high space velocity iron-based desulfurizer.

[0045] The diameter of the desulfurizer is 4 mm, and the average radial crush resistance of the above-mentioned large space velocity iron-based desulfurizer particles is measured to be 51 N / cm.

Embodiment 2

[0047] The preparation method for preparing a large space velocity iron-based desulfurizer provided in this embodiment includes the following steps:

[0048] (1) 80 g of high specific surface iron oxyhydroxide, 20 g of active zinc oxide, and 25 g of a 10 wt % aqueous solution of sodium carboxymethylcellulose were mixed for solid-liquid kneading.

[0049] (2) Extrude and granulate the mixture obtained in step (1), and then dry it at 90° C. for 13 hours to obtain a high space velocity iron-based desulfurizer.

[0050] The diameter of the above-mentioned high space velocity iron-based desulfurizer is 4 mm, and the average radial crush resistance of the above-mentioned high space velocity iron-based desulfurizer particles is measured to be 52 N / cm.

Embodiment 3

[0052] The preparation method for preparing a large space velocity iron-based desulfurizer provided in this embodiment includes the following steps:

[0053] (1) Take 5 ball milling jars, add 18g of high specific surface iron oxyhydroxide and 1g of active zinc oxide into each ball milling jar, then turn on the ball mill for ball milling at a speed of 300 rpm, ball mill for 4 minutes, and let stand after ball milling After settling for 5 minutes, the mixed materials in the 5 ball mill jars were taken out.

[0054] (2) Combine the above-mentioned mixed materials taken out, and then add 40 g of a 5 wt % aqueous solution of sodium carboxymethylcellulose and mix for solid-liquid kneading.

[0055] (3) The mixture obtained by kneading is extruded and granulated, and then dried at 60° C. for 24 hours to obtain a high space velocity iron-based desulfurizer.

[0056] The diameter of the above-mentioned high space velocity iron-based desulfurizer is 4 mm, and the average radial crush r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com