Biomass gasification process and device for strengthening molten salt decoking by nickel-based catalyst

A technology of nickel-based catalyst and gasification device, applied in gasification process, petroleum industry, manufacture of combustible gas, etc., can solve the problems of reducing the yield of product gas and synthesis gas, increasing the difficulty of cleaning system pipelines, etc. Long-term recycling, beneficial to reformation and conversion, and the effect of promoting reformation and conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

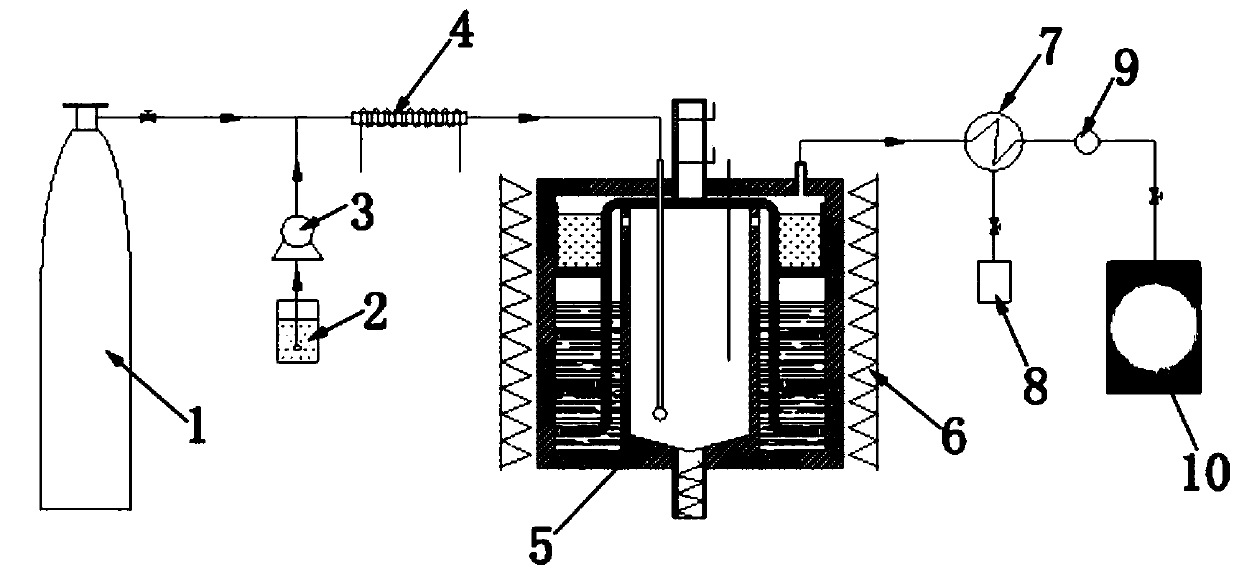

[0047] Embodiment 1: Take the Chinese fir sawdust of block as raw material, with the block particle of 0.25g / sheet compression finalization, the feed mass ratio of water vapor and biomass is 1, and the flow velocity of air is 0.5 L / min, adopts figure 1 The structure of the biomass gasification reaction, but the figure 1 The gasification decoking reactor 5 is replaced by a gasification reactor. There is no molten salt and catalyst inside the gasification reactor. The biomass and gasification agent undergo gasification reaction in the gasification reactor at 750°C, and the products are mainly Ash solids and volatile gases. The results of the examples are as follows: in the volatile matter obtained from biomass gasification, the tar yield was 3.7wt.%.

Embodiment 2

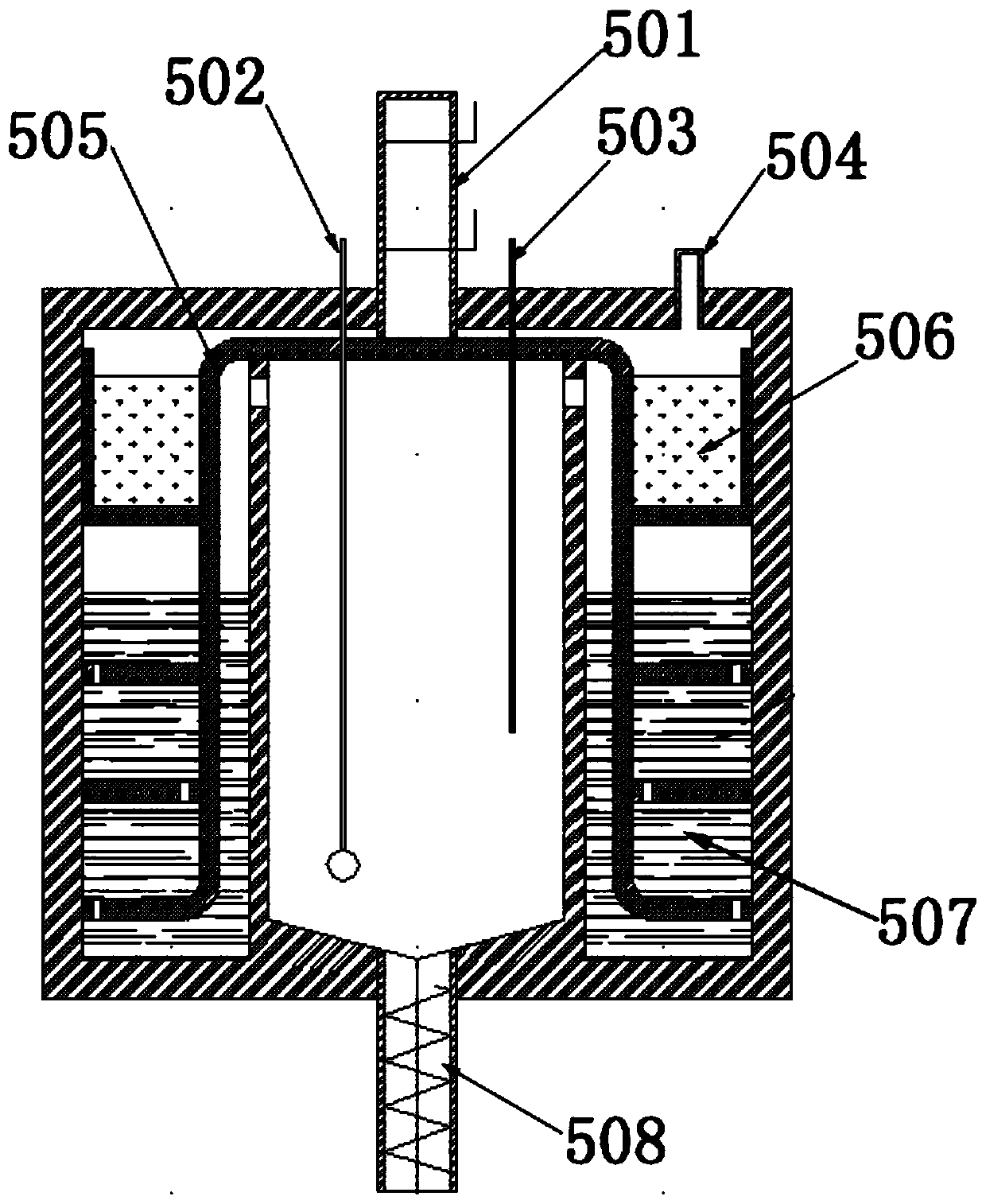

[0048] Embodiment 2: take the fir sawdust of block as raw material, with the block particle of 0.25g / sheet compression finalization, the feed mass ratio of water vapor and biomass is 1, and the flow velocity of air is 0.5 L / min, adopts figure 1 The structure of the biomass gasification reaction, but figure 1 In the gasification decoking reactor 5, only molten salt is used for decoking, and there is no nickel-based catalyst in the gasification decoking reactor 5. Biomass and gasification agent undergo gasification reaction in the gasification chamber of gasification decoking reactor 5 at 750°C, and the products are mainly ash solids and volatile gases, and ash solids come out from the spiral at the bottom of gasification decoking reactor 5 The ash pipe 508 is discharged, and the volatile gas and gasification agent are blown into the molten salt for decoking reaction. After being decoked by the molten salt, the volatile matter and gasification agent enter the condenser to remove...

Embodiment 3

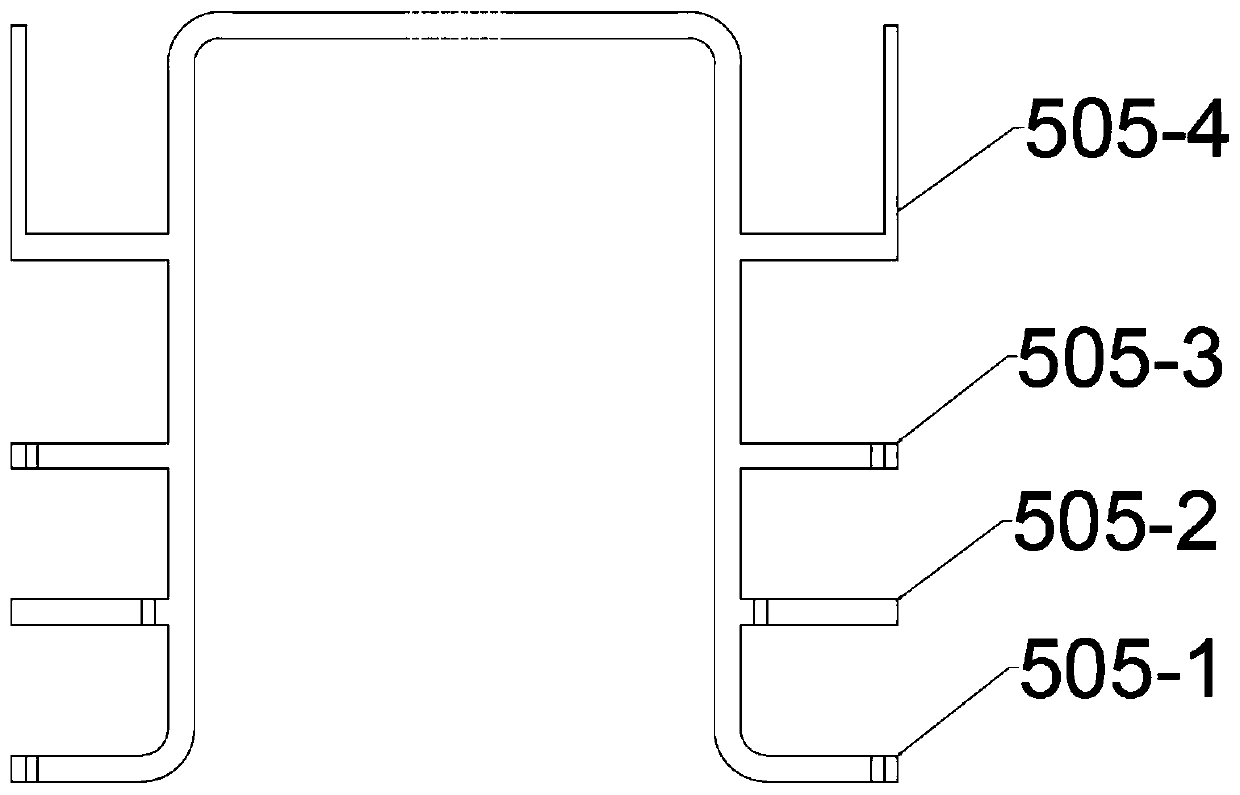

[0049] Embodiment 3: take the Chinese fir sawdust of block as raw material, with the block particle of 0.25g / tablet compression finalization, the feed mass ratio of water vapor and biomass is 1, and the flow velocity of air is 0.5 L / min, adopts figure 1 The structure of the biomass gasification reaction, the nickel-based catalyst used is Ni / Al 2 o 3 , wherein the loading amount of Ni is 15 wt.%, the average particle diameter of the nickel-based catalyst particles is 3 mm, and the sieve hole 504-11 on the tray plate of the concave tray member 505-4 has an aperture diameter of 2.4 mm. The gasification decoking reactor used is as figure 2As shown, the coupled decoking of molten salt and nickel-based catalyst is used, and the biomass and gasification agent undergo gasification reaction in the gasification chamber of gasification decoking reactor 5 at 750 ° C. The products are mainly ash solids and volatile gases. The ash solids are discharged from the spiral ash outlet pipe 50...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com