Preparation method of anti-adhering spray-drying fruit powder

A drying and fruit powder technology is applied in the preparation of fruit powder and the preparation of anti-sticking spray-dried fruit powder, which can solve the problems of flavor, color and nutrient composition, poor anti-sticking effect of drying aids, and limited promotion and application. , to reduce the sticking phenomenon, loose powder without agglomeration, good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

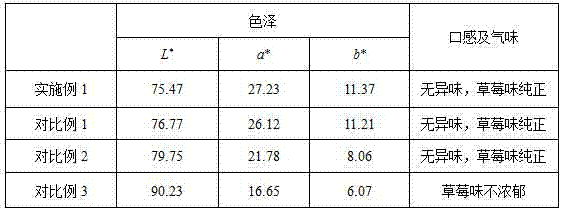

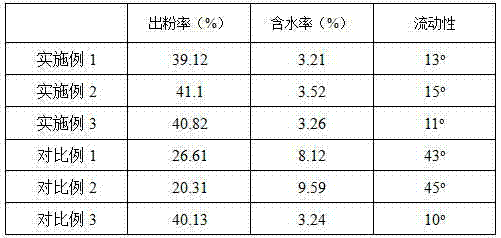

[0024] Embodiment 1 strawberry powder

[0025] Thaw the quick-frozen strawberries at room temperature for about 10 hours, use a single-pass beater to beat, and filter with a 0.6mm pore size filter to obtain strawberry pulp. Preheat the pulp to 70°C, add 0.15% of the weight of the strawberry pulp monoglyceride and 0.1 % calcium lactate stearate, stir evenly, then add drying agent according to the mass ratio of strawberry pulp: maltodextrin: whey protein isolate 60:39:1, and mix with a mixer to obtain a solid content of about 12 o Strawberry pulp from Brix is passed through a colloid mill and a homogenizer. The pressure of the homogenizer is 20MPa, homogenized once, and then spray-dried. The inlet temperature is 165±1°C, the outlet temperature is 85±1°C, and the feed rate is 50ml / min. , to obtain strawberry powder with a moisture content of less than 5%, packed in aluminum foil, 10kg per bag.

Embodiment 2

[0026] Example 2 bayberry powder

[0027] The quick-frozen bayberry was thawed at room temperature for about 10 hours. After beating with a single-channel beater, it was filtered with a 0.6mm pore size filter to remove the pomace to obtain bayberry pulp. Glycerin and 0.1% calcium stearate lactate, stir evenly, then add drying agent according to the mass ratio of bayberry pulp: maltodextrin: whey protein isolate 65:34.5:0.5, and mix with a mixer to obtain a solid Content about 10 o The bayberry pulp of Brix is passed through a colloid mill and a homogenizer. The pressure of the homogenizer is 20MPa, homogenized once, and then spray-dried. The inlet temperature is 160±1°C, the outlet temperature is 80±1°C, and the feed rate is 50ml / min , to obtain bayberry powder with a water content lower than 5%, packed in aluminum foil, 10kg per bag.

Embodiment 3

[0028] Embodiment 3 grape powder

[0029] Thaw the quick-frozen grapes at room temperature for about 10 hours, remove the seeds, beat with a single-channel beater, filter with a 0.6mm aperture filter, remove the pomace to obtain grape pulp, preheat the grape pulp to 70°C, and add 0.15% of the weight of the grape pulp monoglyceride and 0.1% calcium stearate lactate, after stirring evenly, according to the grape pulp: maltodextrin: whey protein isolate mass ratio of 70:30:0.8, add drying agent, and mix with a mixer to obtain solid content of about 11 o Grape pulp from Brix is passed through a colloid mill and a homogenizer. The pressure of the homogenizer is 20MPa, homogenized once, and then spray-dried. The inlet temperature is 170±1°C, the outlet temperature is 90±1°C, and the feed rate is 50ml / min. , to obtain grape powder with a moisture content of less than 5%, packed in aluminum foil, 10kg per bag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com