Light cream produced from anhydrous cream and production process of light cream

An anhydrous butter and production process technology, applied in cream preparations, applications, dairy products, etc., can solve problems such as unfavorable health, insufficient sources, and short shelf life of fresh cream, and achieve stable taste, reduce production costs, and simple operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

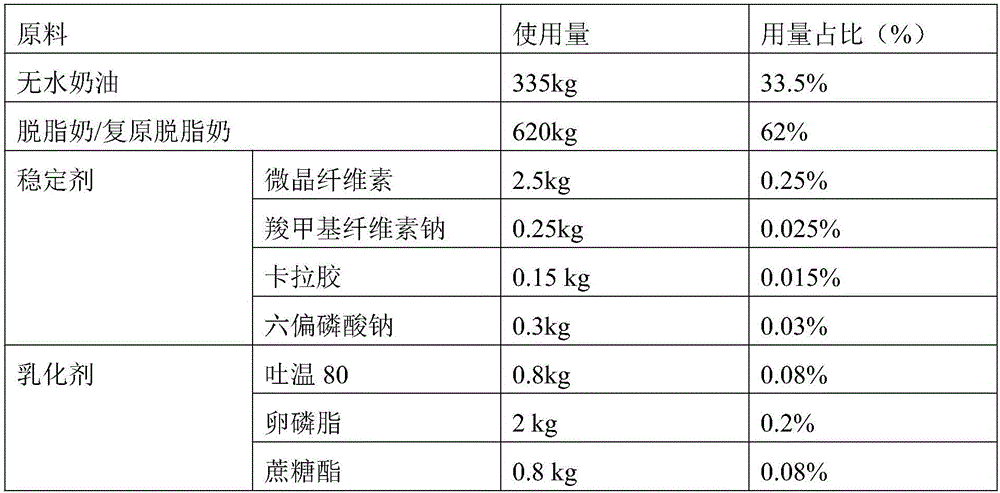

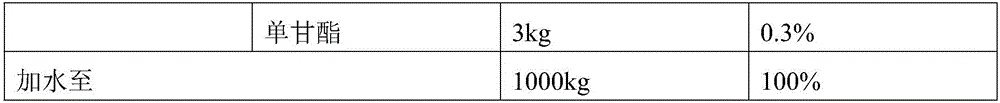

[0029] Utilize anhydrous cream as raw material to produce the cream, according to the production capacity of one ton, the ingredients are as shown in Table 1:

[0030]

[0031]

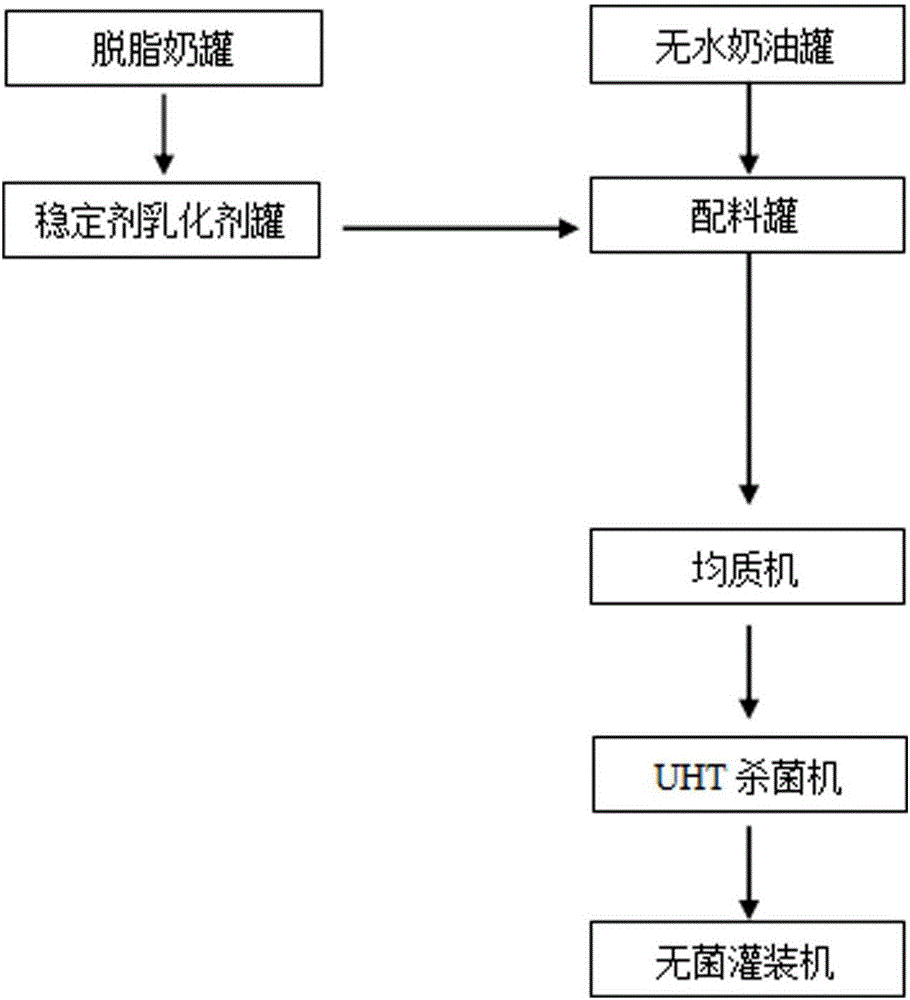

[0032] The production process of the prepared cream, such as figure 1 shown, including the following steps:

[0033] S1: Dissolution of anhydrous cream: Dissolve the anhydrous cream in a heat preservation warehouse at 45-60°C, and pump it into an anhydrous cream tank for temporary storage after it is completely melted;

[0034] S2: Dissolution of stabilizers and emulsifiers: pump skim milk heated to 60-65°C into the tank, first put in liquid lecithin and Tween 80, then put in mixed powder additives, stir for at least 15 minutes to completely dissolve, and set aside ;

[0035] S3: Homogenous mixing: Mix anhydrous cream with skim milk dissolving stabilizers and emulsifiers in a batching tank, and make constant volume with water, stir for at least 5-10 minutes, and ensure that the temperature aft...

Embodiment 2

[0039] Utilize anhydrous cream as raw material to produce the cream, according to the production capacity of one ton, the ingredients are as shown in Table 1:

[0040]

[0041]

[0042] The production process of the prepared cream, such as figure 1 shown, including the following steps:

[0043] S1: Dissolution of anhydrous cream: Dissolve the anhydrous cream in a heat preservation warehouse at 45-60°C, and pump it into an anhydrous cream tank for temporary storage after it is completely melted;

[0044] S2: Dissolution of stabilizers and emulsifiers: pump skim milk heated to 60-65°C into the tank, first put in liquid lecithin and Tween 80, then put in mixed powder additives, stir for at least 15 minutes to completely dissolve, and set aside ;

[0045] S3: Homogenous mixing: Mix anhydrous cream with skim milk dissolving stabilizers and emulsifiers in a batching tank, and make constant volume with water, stir for at least 5-10 minutes, and ensure that the temperature aft...

Embodiment 3

[0049] Utilize anhydrous cream as raw material to produce the cream, according to the production capacity of one ton, the ingredients are as shown in Table 1:

[0050]

[0051]

[0052] The production process of the prepared cream, such as figure 1 shown, including the following steps:

[0053] S1: Dissolution of anhydrous cream: Dissolve the anhydrous cream in a heat preservation warehouse at 45-60°C, and pump it into an anhydrous cream tank for temporary storage after it is completely melted;

[0054] S2: Dissolution of stabilizers and emulsifiers: pump skim milk heated to 60-65°C into the tank, first put in liquid lecithin and Tween 80, then put in mixed powder additives, stir for at least 15 minutes to completely dissolve, and set aside ;

[0055] S3: Homogenous mixing: Mix anhydrous cream with skim milk dissolving stabilizers and emulsifiers in a batching tank, and make constant volume with water, stir for at least 5-10 minutes, and ensure that the temperature aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com