Preparation method of polyolefin alloy

A technology of polyolefin and alloy, applied in the field of preparation of polyolefin alloy, can solve the problem that the gas phase preparation of polybutene alloy material is not mentioned in the literature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

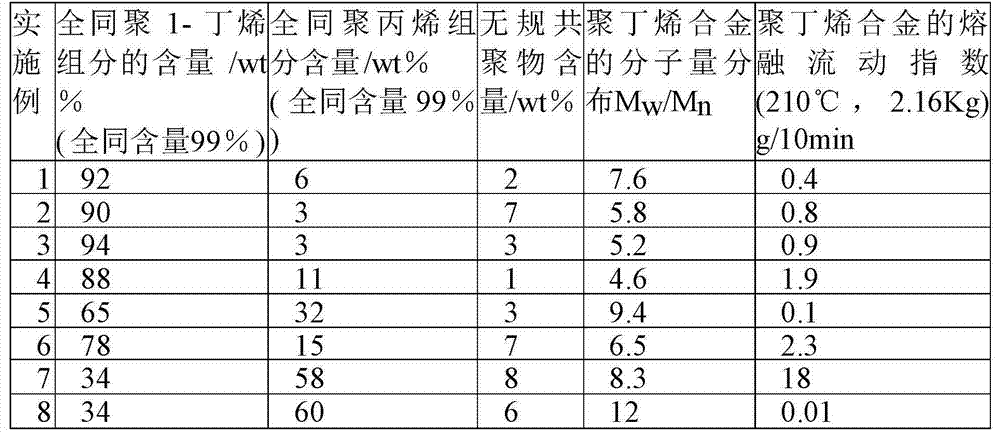

Examples

Embodiment 1

[0051] Preparation of Polybutene Alloy Materials by Continuous Process

[0052] The gas-phase continuous polymerization preparation method of the polybutene alloy material of the present invention is carried out in the following steps on a set of continuously operating pilot plant:

[0053] Prepolymerization is to carry out in a 5L autoclave full of still operation, loaded titanium catalyst feed rate 2g / h (titanium content 2.5-3.5wt%), co-catalyst triethylaluminum feed rate 6g / h (mixed into 5wt% % hexane solution feeding), the external electron donor diphenyldimethoxysilane, the feeding amount is 0.6g / h, the pre-polymerization feeding amount of propylene is 15kg / h, and the feeding is cooled to 5°C. The prepolymerization temperature was 16°C, and the residence time was 20 minutes to obtain an active prepolymer.

[0054] The gas phase polymerization reaction is carried out in two stages. The volume of the two gas phase reactors is 175L. The active prepolymer enters the first st...

Embodiment 2

[0057] Preparation of Polybutene Alloy Materials by Continuous Process

[0058] Adopt the same continuous polymerization device and operating process as in Example 1, the cocatalyst is changed into triisobutylaluminum, the feed rate is 4g / h (being mixed with the hexane solution feed of 5wt%), and the external electron donor is changed into For diisopropyldimethoxysilane, the pre-polymerization monomer is changed to liquid-phase propylene feed rate to 0.5g / h, and the pre-polymerization time is changed to 1h. Others are the same as embodiment 1.

[0059] The final product obtained is a fine powder spherical particle, and the properties of the polybutene alloy are shown in Table 1.

Embodiment 3

[0061] Preparation of Polybutene Alloy Materials by Continuous Process

[0062] The same continuous polymerization apparatus as in Example 1 was used. Prepolymerization is carried out in a 5L autoclave full of still operation, catalyst active component feed rate 2g / h, cocatalyst triethylaluminum feed rate 6g / h (mixed with 5wt% hexane solution feed) , external electron donor diphenyldimethoxysilane, feed amount 0.6g / h, butene-1 feed amount 16kg / h for prepolymerization, prepolymerization temperature 5°C, residence time 30min to obtain active polymer.

[0063] The gas-phase polymerization reaction is carried out in two stages. The volume of the two gas-phase reactors is 175L. The active prepolymer enters the first-stage reactor, and the mixed gas of butene-1 and hydrogen is pressed into the gas-phase polymerization. Butene-1 1 The gas phase composition is 95mol%, the hydrogen gas phase composition is 5mol%, the polymerization pressure is 0.9MPa, the polymerization temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com