Patents

Literature

46results about How to "Expand sales radius" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Normal-temperature drinking type yoghourt and preparation method thereof

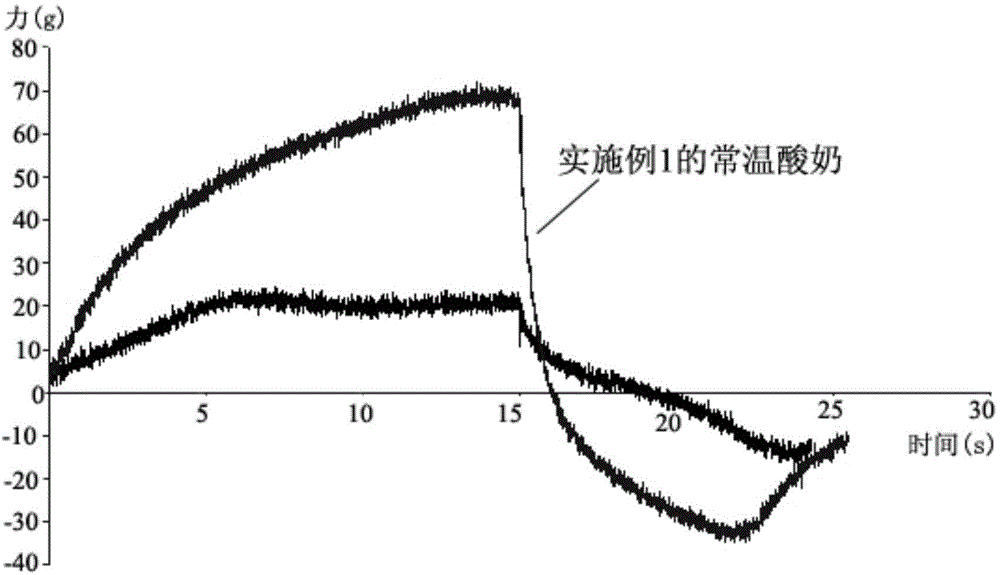

The invention discloses normal-temperature drinking type yoghourt and a preparation method thereof. The normal-temperature drinking type yoghourt comprises the following raw materials in percentage by weight: 56.6%-60% of concentrated raw milk, 1*10<6>-7*10<9>cfu / mL of a fermenting agent, 0.03-0.5% of a stabilizing agent, a proper amount of a sweetening agent and a proper amount of water, wherein the stabilizing agent is selected from one or multiple of pectin, soybean polysaccharide and gellan gum, and the percentage is the mass percent of the stabilizing agent, accounting for the total mass of the normal-temperature drinking type yoghourt. The preparation method comprises the following steps: (1) homogenizing the concentrated raw milk and milk powder and sterilizing to obtain a sterilized liquid mixture A; (2) cooling, adding the fermenting agent for fermentation, overturning a jar by back pressure, homogenizing and cooling again; (3) uniformly mixing with the sterilized liquid mixture A, adjusting the acidity, homogenizing so as to obtain a liquid mixture B, wherein the liquid mixture A comprises the stabilizing agent, the sweetening agent and the water; and (4) sterilizing the liquid mixture B. The normal-temperature drinking type yoghourt and the preparation method disclosed by the invention have the advantages that the requirements of heat treatment for the viscosity of the yoghourt and the adding amount of the stabilizing agent are effectively reduced, the obtained normal-temperature drinking type yoghourt is good in fluidity and smooth in taste and has no obvious layering condition after being stored for 6 months under the normal temperature.

Owner:BRIGHT DAIRY & FOOD

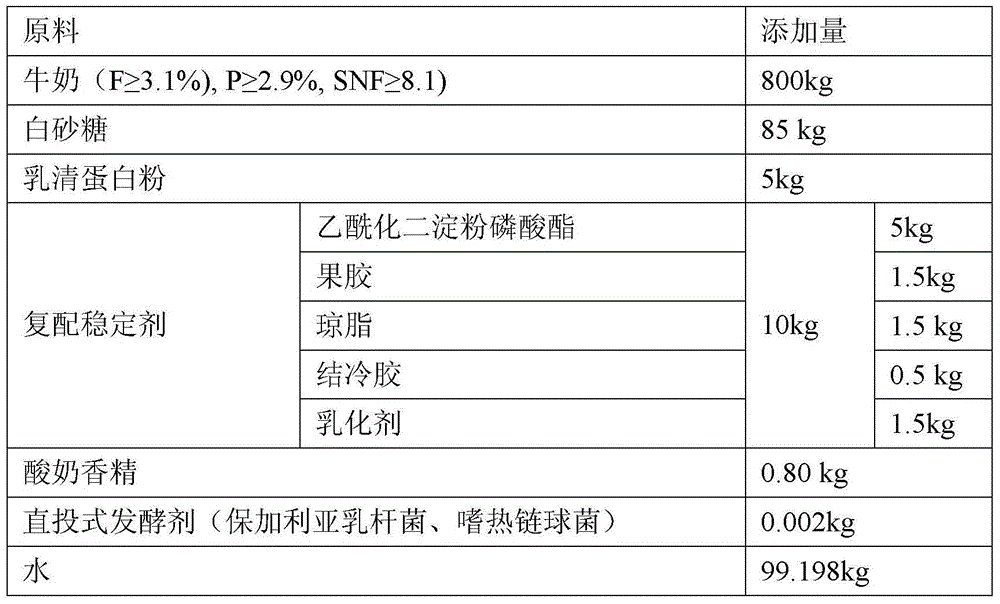

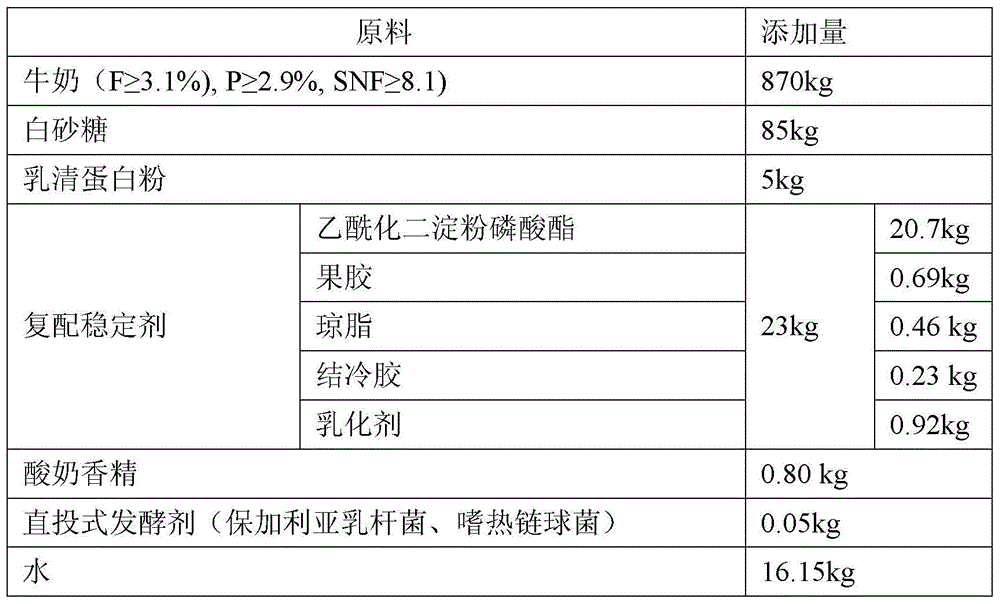

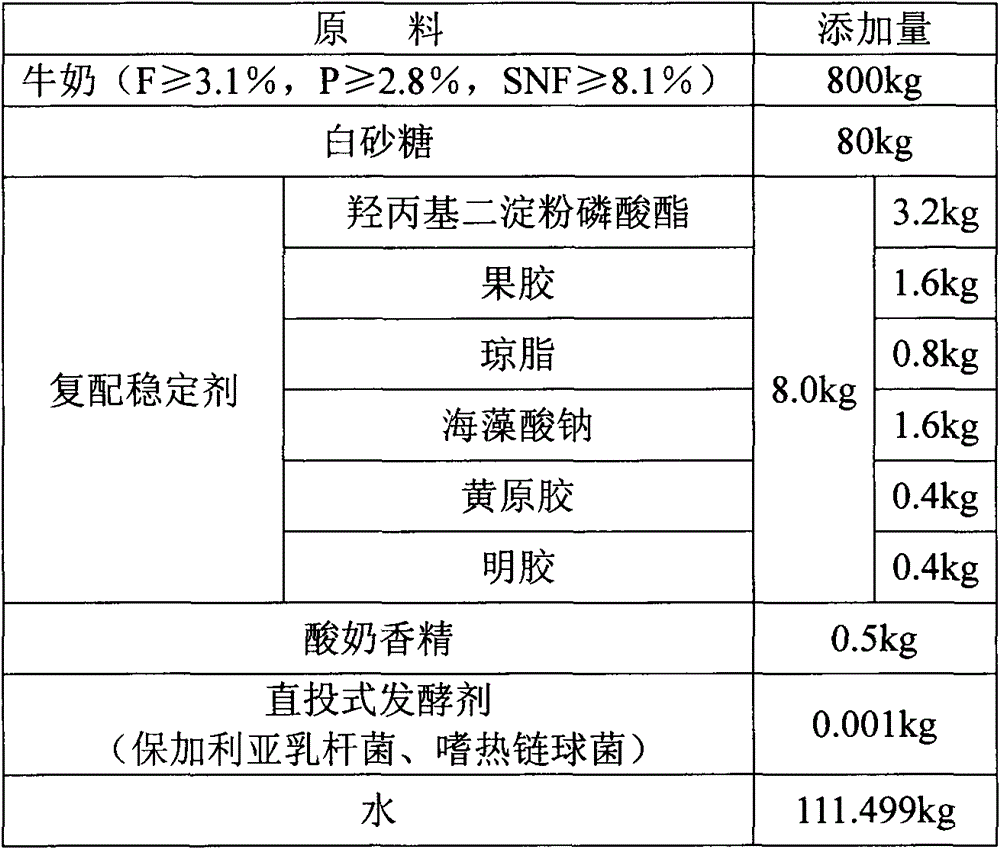

Compounded stabilizer, normal temperature yoghurt containing compounded stabilizer, and preparation method of yogurt

The invention relates to a compounded stabilizer, normal temperature yoghurt containing the compounded stabilizer, and a preparation method of the yogurt. The compounded stabilizer comprises, by mass, 50-90% of esterified modified starch, 3-15% of pectin, 2-15% of agar, 4-15% of an emulsifier and 1-5% of gellan gum. The invention also provides normal temperature yoghurt containing the compounded stabilizer, and a preparation method of the yogurt. The compounded stabilizer has good process tolerance, improves the viscosity stability of a technology processed normal temperature yoghurt system and the viscosity recovery stability of a subsequent product, and allows the viscosity of yogurt at normal temperature of 20-40DEG C to be similar or greater than the viscosity of yogurt refrigerated at normal temperature of 3500-5000cp. The normal temperature yogurt prepared in the invention can be stored at normal temperature of 20-40DEG C for 4-6 months, and allows high quality yogurt to be drunk in remote cold chain lacking places.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Method for preparing nutrient dried bean curds

InactiveCN102885165AAdvantages and Notable ImprovementsInhibit growthCheese manufactureFood scienceMicroorganismDry bean

The invention discloses a method for preparing nutrient dried bean curds. The method comprises the following steps of: (1) soaking selected fresh soybeans into a special soak solution for 8 to 13 hours; (2) grinding the fresh soybeans in the presence of water to obtain soybean milk of which the particle size is smaller than 3 micrometers, and filtering; (3) boiling the soybean milk twice and thencurdling the boiled soybean milk, solidifying, molding and pressing; (4), rinsing by using a sodium carbonate (Na2CO3) solution, wherein the treatment temperature is between 85 and 95 DEG C, and the treatment time is 3 to 6 minutes; and (5), marinating, performing centrifugal dewatering, drying, cooling, packaging and sterilizing to obtain the nutrient dried bean curds. By the method, microorganisms can be effectively prevented from growing after products are packed, so that the shelf life of the dried bean curds is prolonged.

Owner:ANHUI RENRENFU BEAN IND

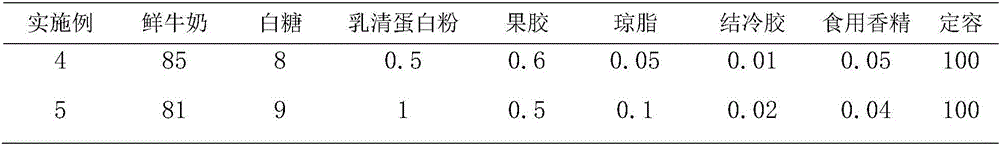

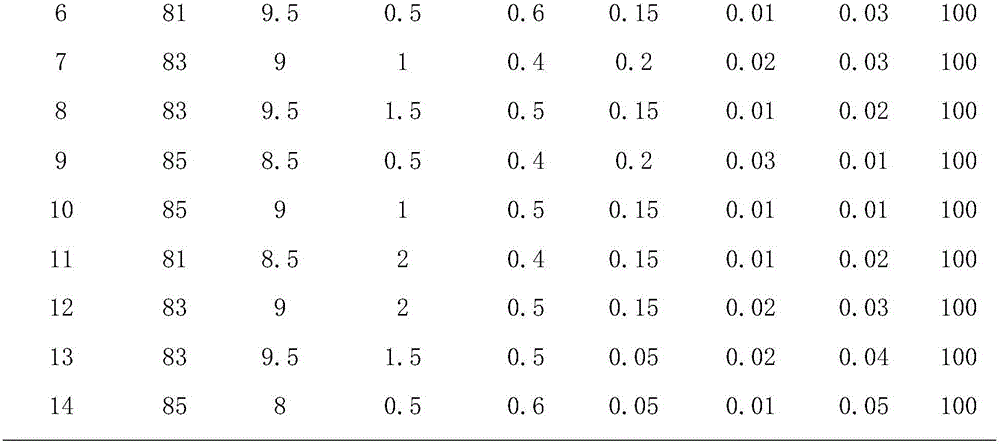

Normal-temperature drinking type yoghourt and preparation method thereof

The invention discloses normal-temperature drinking type yoghourt, which is prepared from the following raw materials in percentage by mass: 80 to 86 percent of fresh milk, 7 to 12 percent of white sugar, 0.5 to 2 percent of lactalbumin powder, 0.4 to 0.7 percent of pectin, 0.04 to 0.25 percent of agaragar, 0 to 0.03 percent of gellan gum, 0 to 0.05 percent of food flavoring and the balance water. The normal-temperature drinking type yoghourt provided by the invention has the advantages that more than 80 percent of pasture high-quality fresh milk is used as the main raw materials; the lactalbumin powder and the white sugar are added; food additives such as the pectin, the agaragar and the gellan gum are used as auxiliary materials; firstly, the milk is preheated, and is mixed with the raw materials such as the lactalbumin powder, the white sugar, the agaragar and the gellan gum; the materials are subjected to homogenizing, sterilization, cooling and fermentation for use. Through the secondary proportioning process, the pectin is singly dissolved and cooled and is then mixed with yoghourt; the 75-110 DEG C and 5-30s pasteurization heat treatment can be simultaneously performed. The normal-temperature drinking type yoghourt has the advantages that the requirement of a national standard of acidified milk that the flavor yoghourt needs to contain more than 80 percent of raw material milk is met; the stabilizing agent addition is reduced; the flowability of the produced yoghourt is good; the mouthfeel and the state thickness degree are proper.

Owner:YUNNAN XINXIWANG DENGCHUAN DIEQUAN DAIRY +1

Organic and inorganic cooperation fertilizer and application thereof

InactiveCN105085082AIncrease profitSolve difficult problems that are not easy to pursueFertilizer mixturesManufacturing technologyManganese

The invention relates to the technical field of fertilizer manufacturing, in particular to organic and inorganic cooperation fertilizer and an application thereof. The organic and inorganic cooperation fertilizer comprises, by mass, the following components of 10-30 parts of chelating state medium trace element fertilizer and 70-90 parts of organic fertilizer, wherein the chelating state medium trace element fertilizer is formed by cooperatively and evenly stirring cooperation medium trace element fertilizer and a chelating agent water solution according to the mass ratio of 1-5:1, and the cooperation medium trace element fertilizer comprises the components of calcium nitrate, magnesium sulfate, ferrous sulfate, copper sulfate, zinc sulfate, manganese sulfate, sodium decaborate, ammonium molybdate and amino acid chelating selenium. The organic and inorganic cooperation fertilizer is suitable for top dressing and fertilizer application of crops, organic components and inorganic components contained in the fertilizer can achieve the effects of advantage complementing and synergistic functioning, a better function is achieved, the utilization rate of the inorganic components is high, top dressing of the organic fertilizer is performed in time, and meanwhile the problem that top dressing of medium trace elements is difficult is solved.

Owner:郭云征

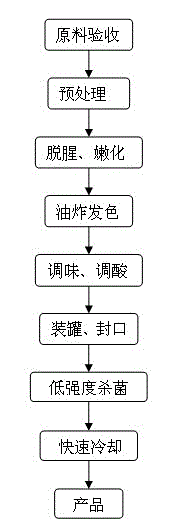

Processing method of dish-type instant food pickled cabbage fish packed to be shaped like a bowl and preserved at normal temperature

The invention discloses a processing method of dish-type instant food pickled cabbage fish packed to be shaped like a bowl and preserved at normal temperature, belonging to the technical field of processing and preserving of aquatic food. According to the processing method, a fresh fish and pickled vegetables are taken as primary materials, and the dish-type instant food pickled cabbage fish product packed in the bowl and preserved at normal temperature is prepared by the processes of preprocessing the raw materials, deodorizing and tenderizing the fish, frying to change color, seasoning, adjusting acid, tinning, sealing, conducting low-intensity sterilization and rapidly cooling. The dish-type instant food pickled cabbage fish product produced by the method disclosed by the invention completely preserves original flavor, texture, color and luster and nutrition of pickled cabbage fish dish, is high in safety and long in quality guarantee period, and is packaged by a bowl-shaped container; no chemical preservative is added in the processing process; and the dish-type instant food pickled cabbage fish is simple to open, convenient to eat, and wide in market prospect, can be heated by microwaves, and meets the demands on food nutrition and taste required by modern consumers and rapid pace of life.

Owner:JIANGNAN UNIV

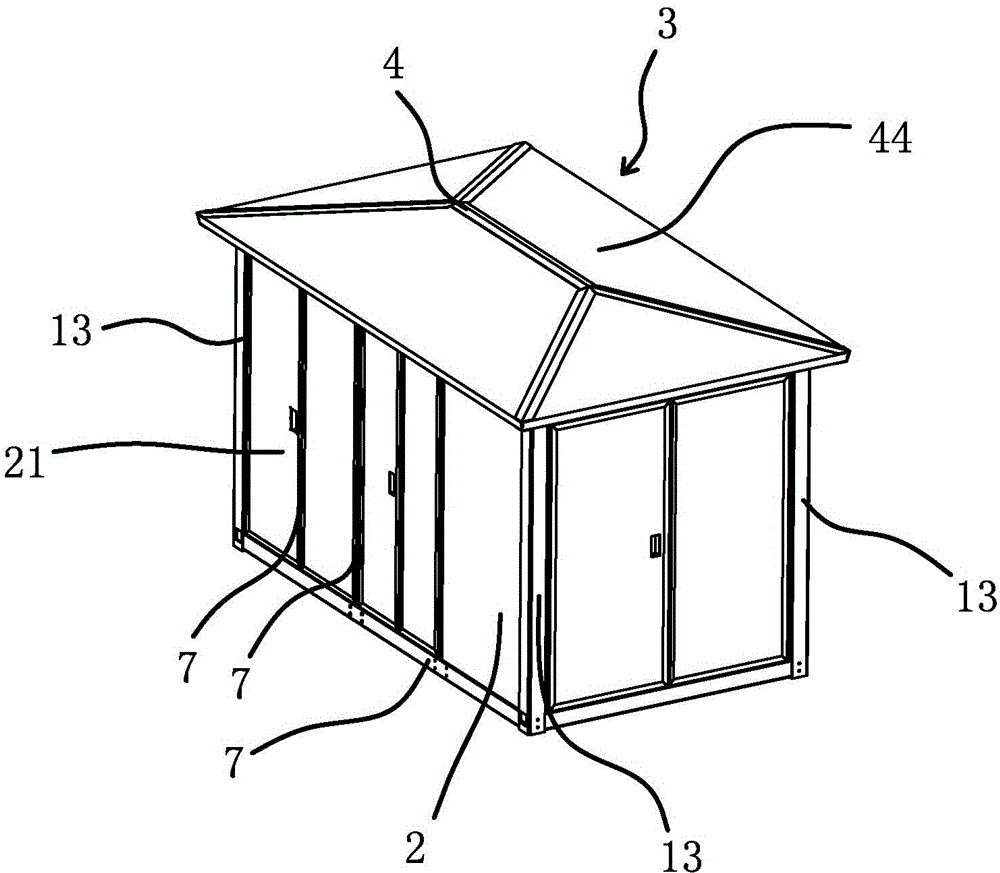

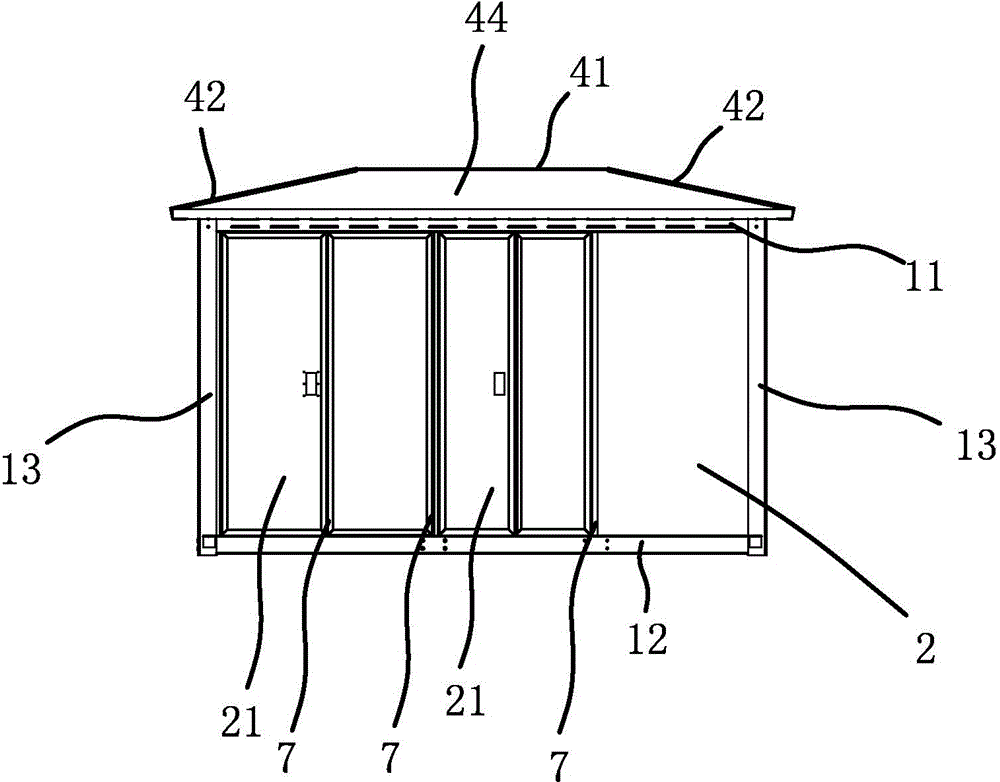

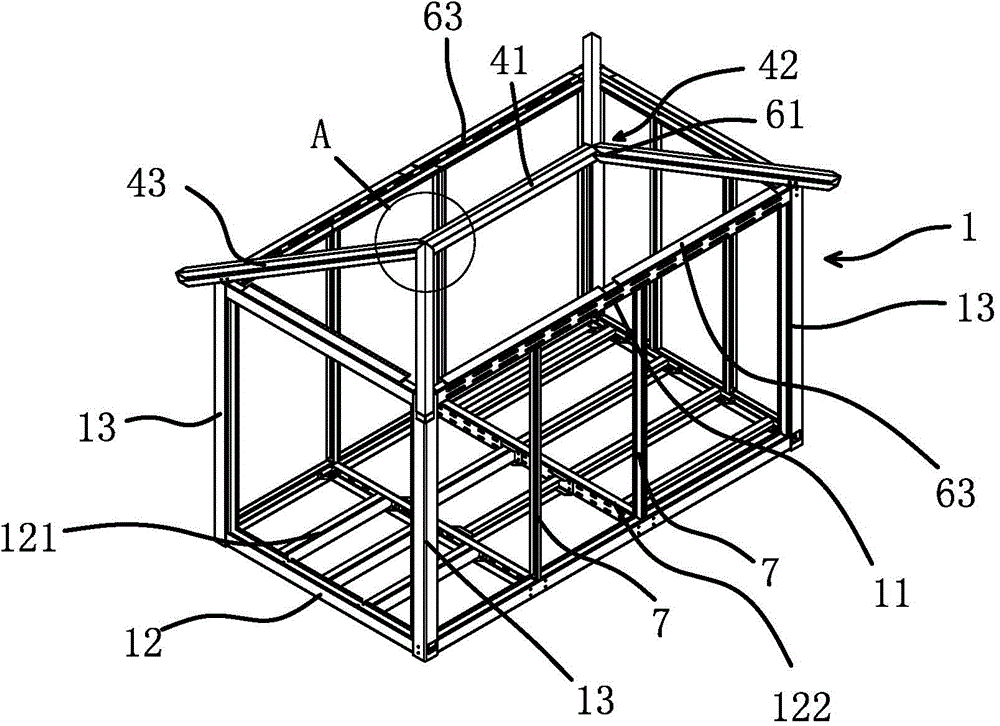

Substation room

ActiveCN104405155AExpand sales radiusEasy to transportBuilding roofsTransformer housesElectricityEngineering

The invention provides a substation room, belongs to the electricity field and solves the technical problem of the existing substation room, which is inconvenient to transport and mount. The substation room comprises a cubic framework, a pitched roof arranged at the top of the framework and a wall plate and a door arranged at the side of the framework for closing the side of the framework, the framework is composed of the rectangular top framework, the rectangular bottom framework and four stand columns connected with four corners of the top framework and the bottom framework; the pitched roof comprises the roof framework and the roof cover plate, the roof framework comprises a roof girder and two roof brackets, the roof girder is located above the middle of the top framework, one end of each roof bracket is respectively connected to two ends of the roof girder while the other end of each roof bracket respectively connected with the top framework through the bolts, the roof cover plate is fixed between the roof girder and the roof bracket. The substation room has the advantage of convenient installation.

Owner:BOEN SOLAR TECH +1

Waxberry fresh keeping method

InactiveCN101878806AExtended shelf lifeLengthen sales seasonFruit and vegetables preservationAgricultural scienceRefrigerated temperature

The invention discloses a waxberry fresh keeping method, which adopts 1-MCP for carrying out fresh keeping treatment on waxberry fruit products. The invention can be used for carrying out fresh keeping operation on the waxberry in a refrigerator, and can be used for carrying out fresh keeping operation on the waxberry in long-distance sale transportation. When the invention is adopted for refrigerator fresh keeping, the storage life of the waxberry can be prolonged from the original 7 to 10 days to 40 to 60 days. When the invention is used for long-distance sale transportation fresh keeping, the fresh keeping period of the waxberry can be prolonged from the original 3 to 4 days to 6 to 8 days, and the sale radius of the waxberry fruit products is greatly enlarged. The invention can solve the problems of short market selling time and small sale range radius of the waxberry.

Owner:郭江仙 +1

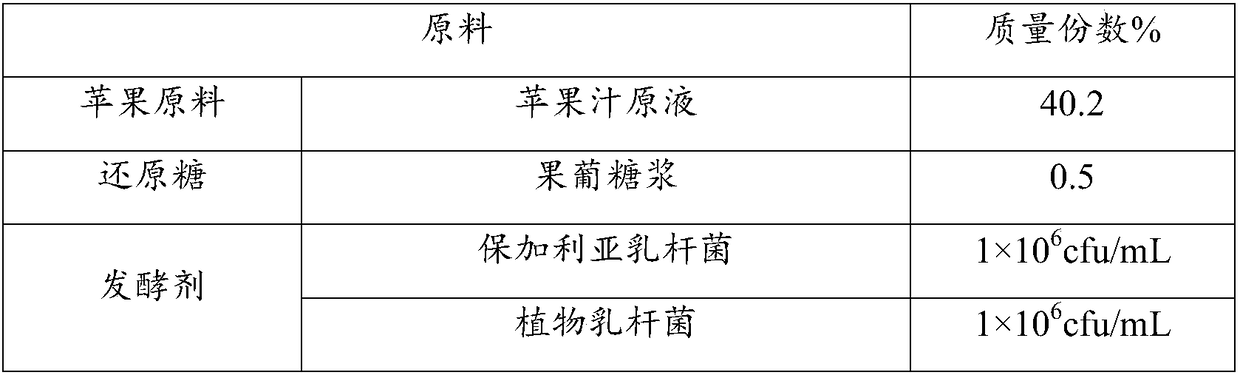

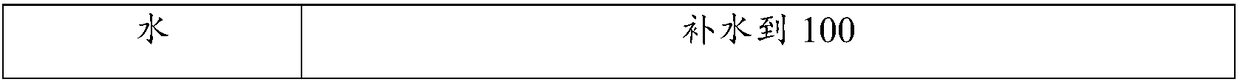

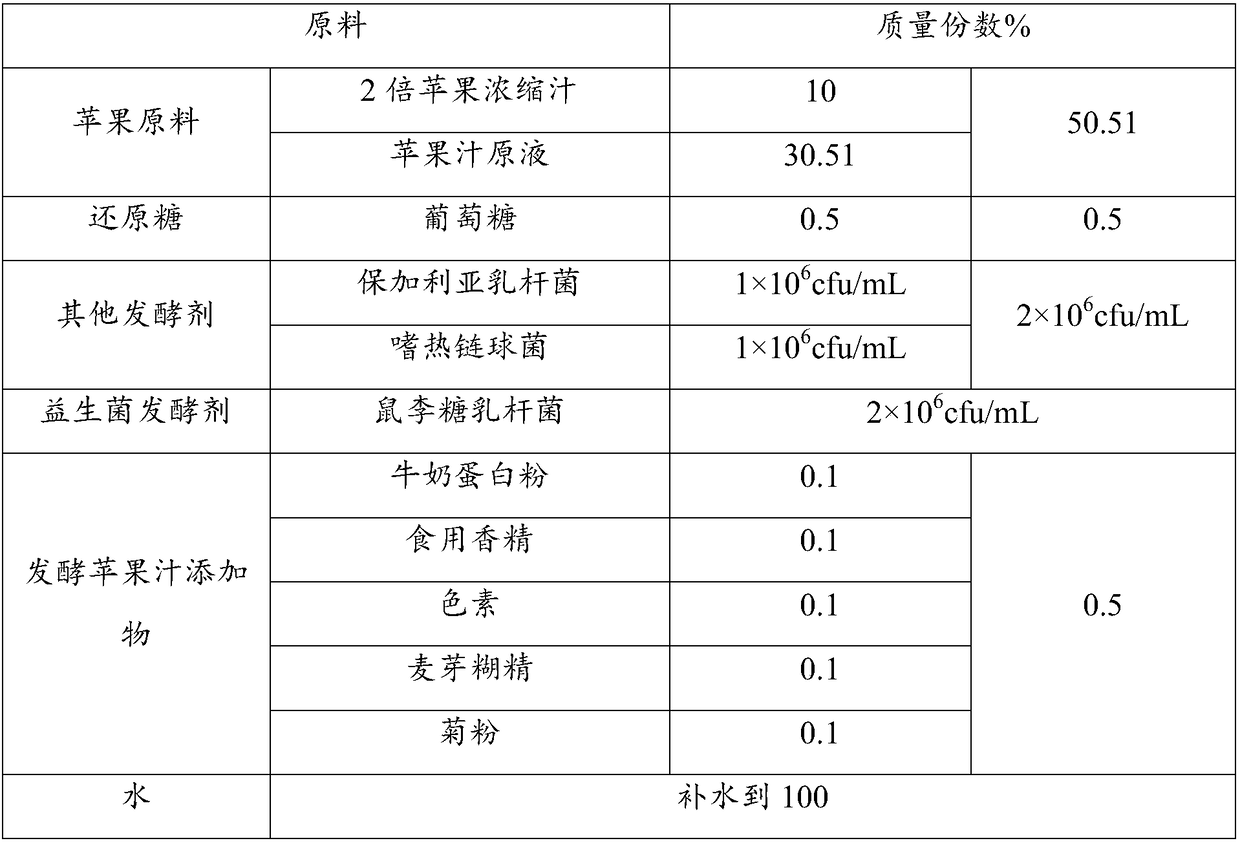

Fermented apple juice and preparation method thereof

The present invention discloses fermented apple juice and a preparation method thereof. The preparation method comprises the following steps: S1: evenly mixing apple raw material juice, reducing sugarand water, and subjecting the mixture to filtration and sterilization to obtain mixed solution; S2: inoculating the mixed solution with starter cultures when the mixed solution is cooled to preset temperature, and carrying out fermentation at the preset temperature to obtain fermented apple juice; and S3: homogenizing and refining the fermented apple juice. The reducing sugar includes, but not limited to, one or more of glucose, galactose, lactose and high fructose corn syrup, and the mass percentage of the reducing sugar in the mixed solution is 0.5%-2%; and the starter cultures include, butnot limited to, probiotics, the addition amount of the probiotics is 1x10<6>-1x10<9> cfu / mL, and the time of fermentation is 12-96 h. The fermented apple juice is free of stabilizer addition, stablein system, fresh and cool in mouthfeel, sweet, sour and palatable in taste, low in viscosity, good in fluidity and capable of being used directly or used as an ingredient in other products, and the preparation method of the fermented apple juice is simple in process and suitable for large-scale production in factories.

Owner:BRIGHT DAIRY & FOOD CO LTD

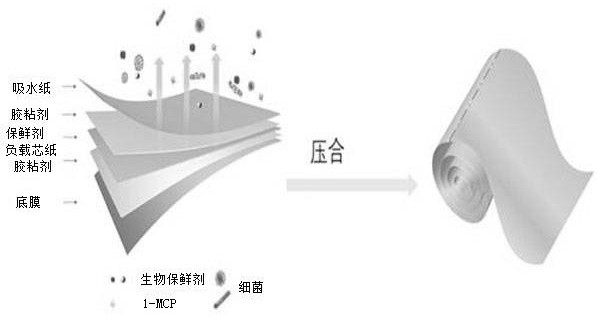

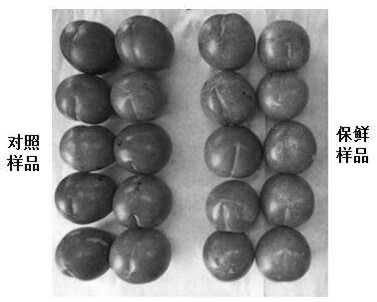

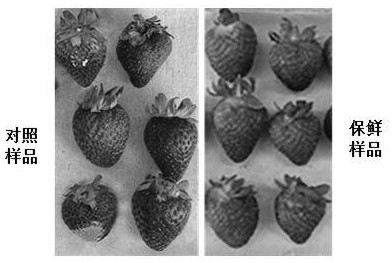

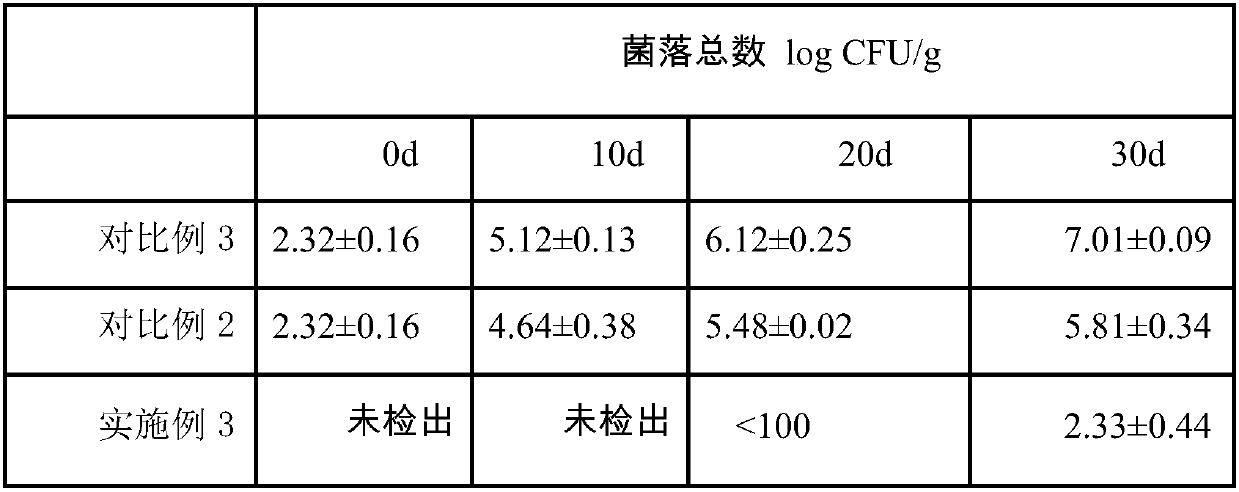

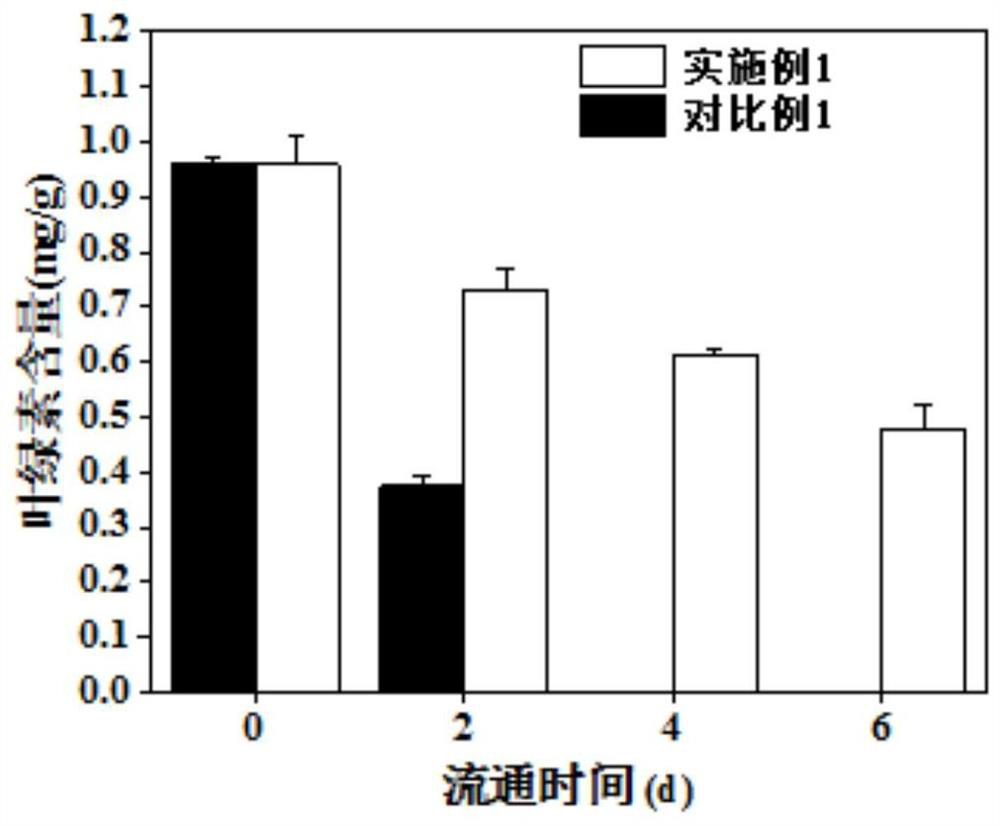

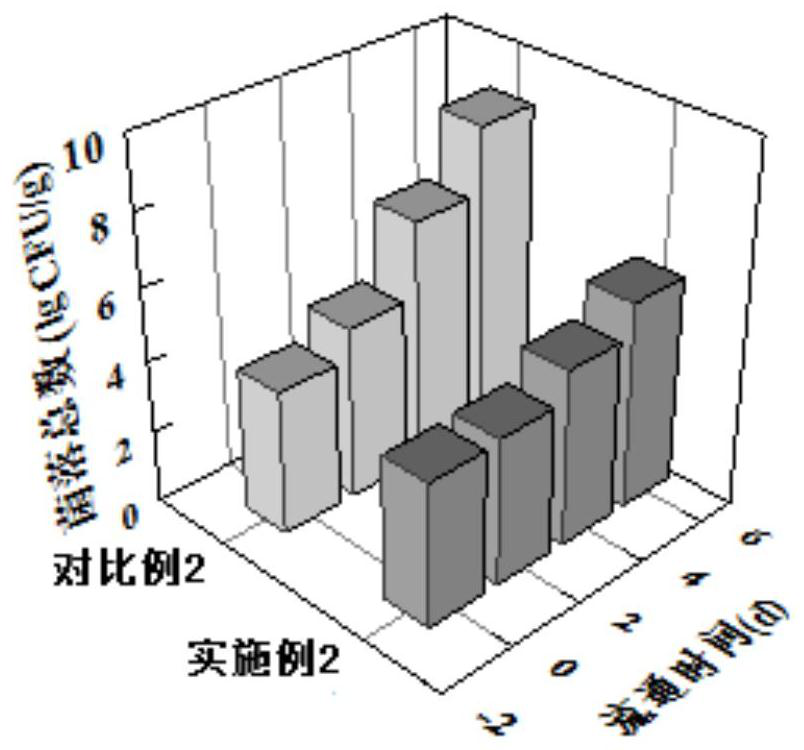

Preparation method of green slow-release fresh keeping paper applied to fresh keeping of fruits and vegetables

PendingCN112369464ASimple and fast operationLow requirements for production equipmentFlexible coversWrappersBiotechnologyEngineering

The invention discloses a preparation method of green slow-release fresh keeping paper applied to fresh keeping of fruits and vegetables, and belongs to the field of application of food fresh keepingmaterials. The preparation method comprises the following specific steps: step I, preparing biological fresh keeping agent loaded core paper; II, preparing a fruit and vegetable respiration inhibitorloaded bottom film; and III, heating and pressing the biological fresh keeping agent loaded core paper and the fruit and vegetable respiration inhibitor loaded bottom film to obtain the green slow-release fresh keeping paper. The green slow-release fresh keeping paper applied to fresh keeping of fruits and vegetables is prepared by taking a biological fresh keeping agent as a main material and absorbent paper or non-woven fabric as an auxiliary material and adopting a layer-by-layer film coating method, and the product is stable in physical and chemical properties, easy to industrialize, simple in production process and long in action time of the biological fresh keeping agent, and has a good application prospect.

Owner:BOHAI UNIV

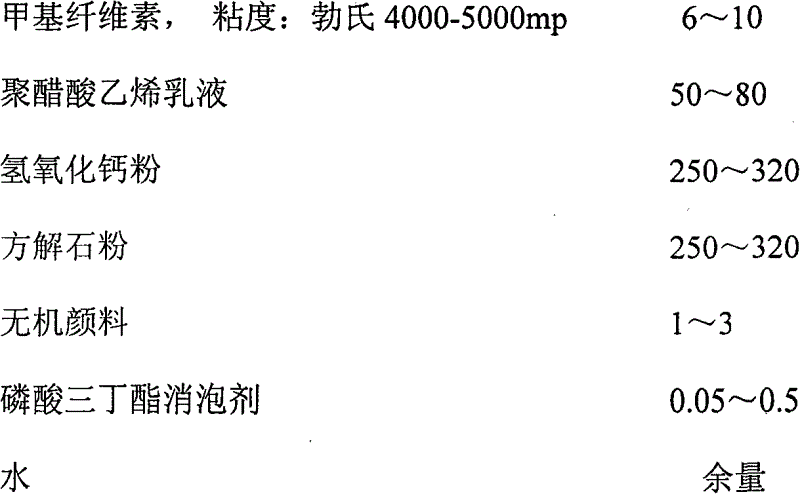

Toughened tile-like coating

The invention discloses a toughened tile-like coating, which comprises the following main components in part by weight: 6 to 10 parts of methylcellulose, 50 to 80 parts of polyvinyl acetate emulsion, 250 to 320 parts of calcium hydroxide powder, 250 to 320 parts of calcite powder, 1 to 3 parts of pigment, 0.05 to 0.5 part of antifoaming agent and the balance of water. A preparation method comprises the following steps of: adding water in an amount which is two times that of the polyvinyl acetate emulsion into the polyvinyl acetate emulsion for diluting; adding the methylcellulose into the residual water, dissolving for 24 to 48 hours, dispersing, and standing for later use; adding the two kinds of solution into a dispersion machine for mixing, adding the pigment and the antifoaming agent, and dispersing; and adding the calcium hydroxide powder and the calcite powder, uniformly dispersing, and grinding to prepare the tile-like coating. The coating does not crack, and has water scrubbing resistance which can reach the national standard of an outer wall coating; and the coating has the advantages of smooth, firm and durable surface, water and fire resistance, low cost, long storage period and the like, and is easy to transport remotely.

Owner:梁振华

Powder steel ceramics-like coating

The invention provides a powder steel ceramics-like coating. The formula of the powder steel ceramics-like coating comprises the following components in percentage by weight: 40 to 60 percent of lightcalcium carbonate, 20 to 30 percent of crystalline hydrate of 3-magnesium oxide and 4-silicon oxide, 1 to 5 percent of titanium dioxide, 5 to 20 percent of JN rubber powder, 2 to 6 percent of urea and proper amount of aluminum silicate. The powder steel ceramics-like coating is prepared by simply evenly mixing the raw materials of all components to form powder without requiring special productionprocesses. The powder steel ceramics-like coating is only mixed with cold water to use, so that the powder steel ceramics-like coating has the advantages of easy production and use, low transportation cost, big sale radius, low cost, easy wide-range promotion; and moreover, the powder steel ceramics-like coating also has the advantages of high hardness, good steel effect, tightness, smoothness, delicacy, water resistance, fire retardancy, and stable quality.

Owner:BEIJING YUJIAMING TRI STATE ION RES INST

Fresh keeping method of ready-to-eat seasoned crayfish

InactiveCN107668168AReduce microbial countReduce freshnessGaseous food ingredientsMeat/fish preservation using chemicalsReady to eatShrimp

The invention discloses a fresh keeping method of ready-to-eat seasoned crayfish. The fresh keeping method comprises the following steps of performing modified atmosphere packaging on seasoned and cooked crayfish, performing irradiation sterilization treatment with cobalt 60, wherein gas inflated for modified atmosphere packaging consists of the following substances in percentage by volume: 25-40%of CO2 and 60-75% of N2, and the irradiation dose is 4kGy-8kGy. According to the fresh keeping method disclosed by the invention, the shelf life of the ready-to-eat flavored crayfish can be notably prolonged, and the ready-to-eat flavored crayfish is free from residues, so that the selling range of the ready-to-eat flavored crayfish is greatly enlarged. On the basis of guaranteeing the bacteria resisting effect, the appearance of boxes can be well guaranteed, the condition that the packing boxes are sunken can be avoided, the condition that shrimp meat protein is denatured is not liable to cause, and the elasticity of the shrimp meat can be guaranteed.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES +1

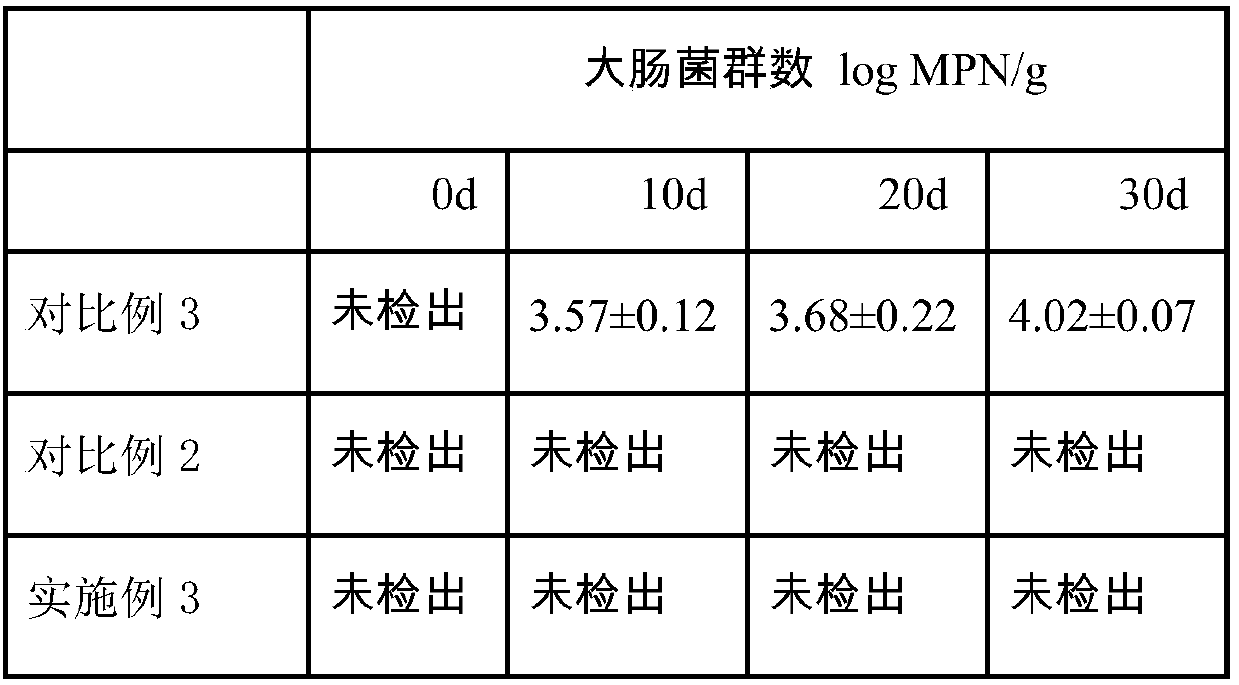

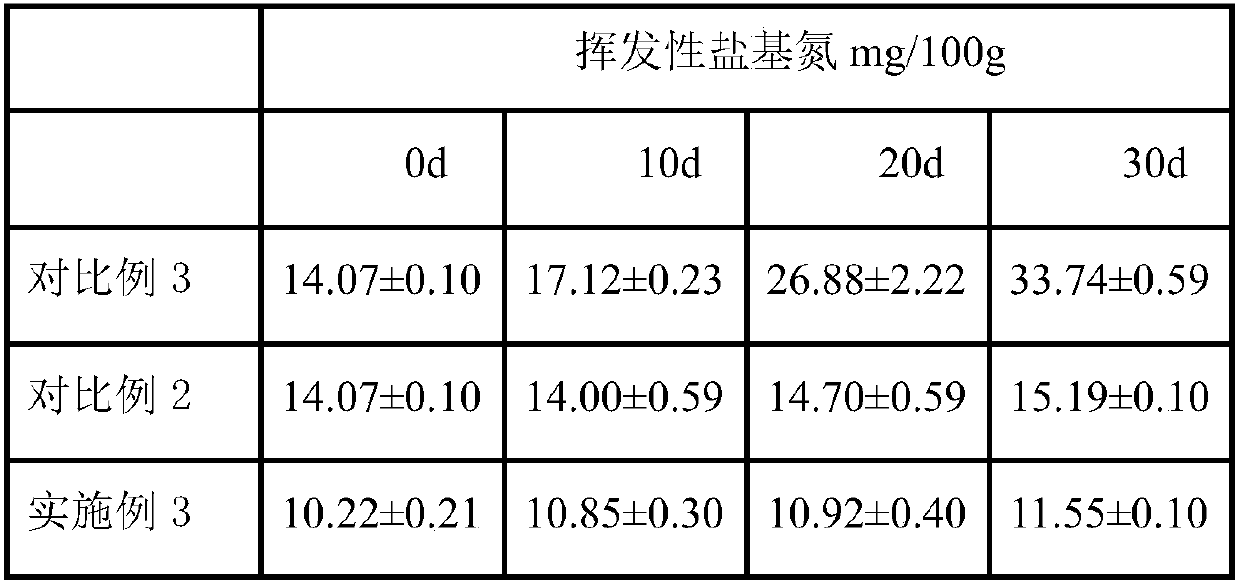

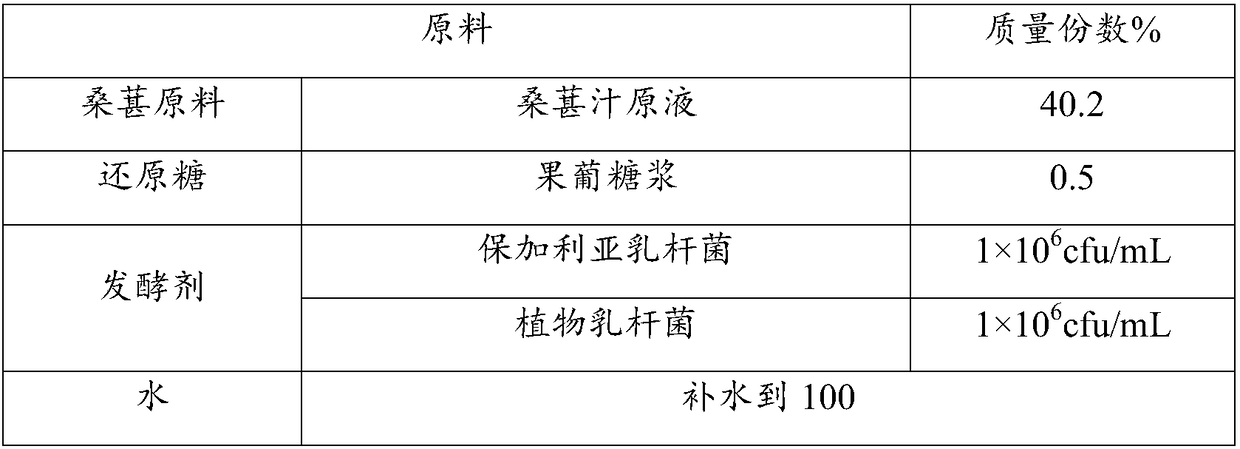

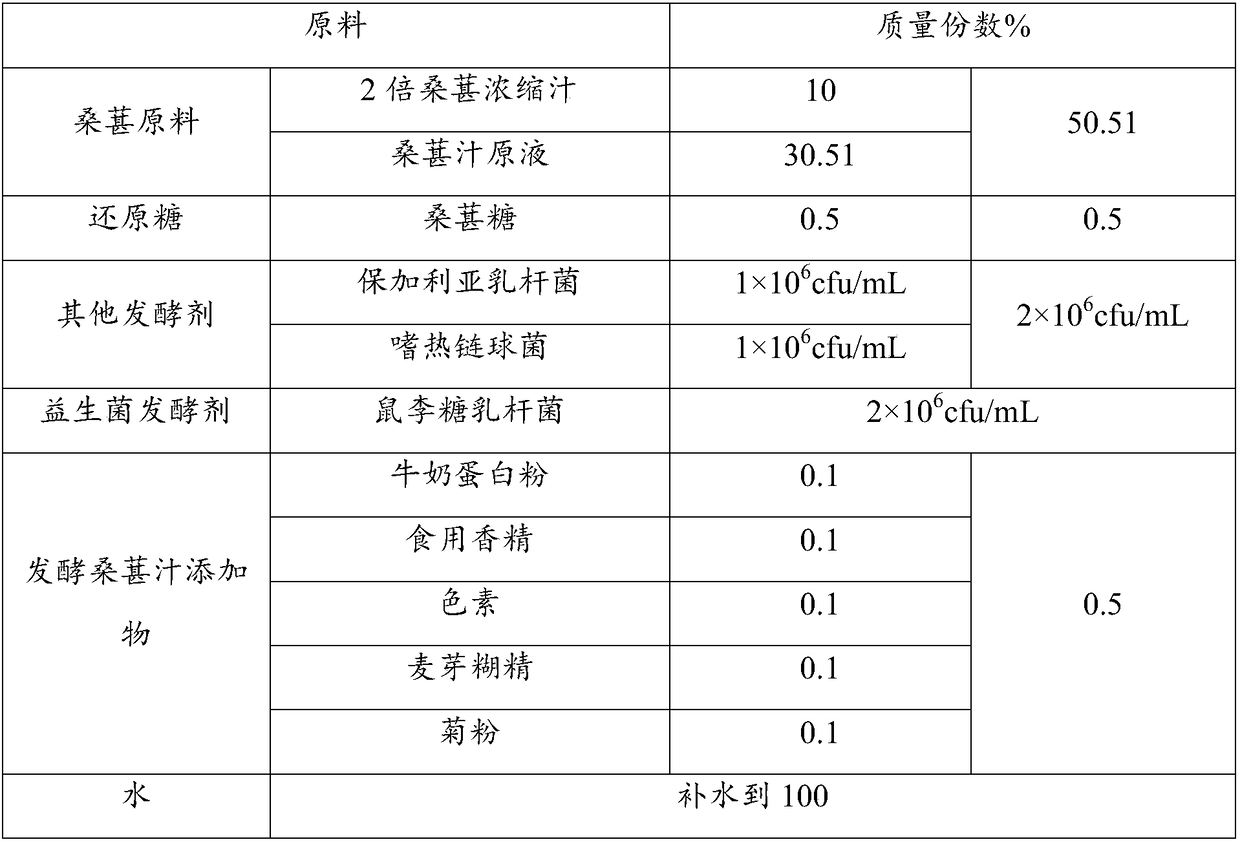

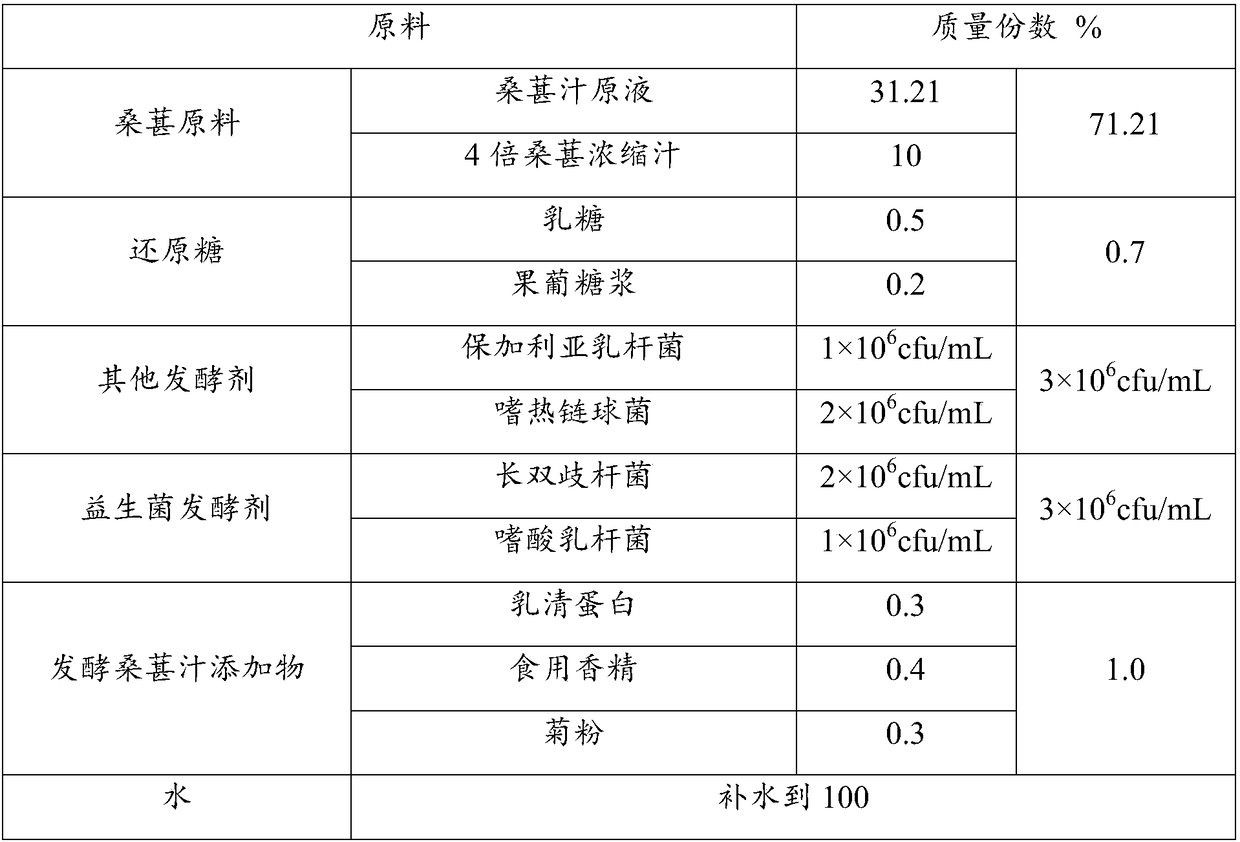

Fermented mulberry juice and making method thereof

InactiveCN108125087AReduce typesLow viscositySugar food ingredientsFood ingredient functionsHigh-fructose corn syrupAdditive ingredient

The invention discloses fermented mulberry juice and a making method thereof. The making method comprises the following steps of S1, uniformly mixing mulberry raw material juice with reducing sugar and water, and performing filtration and sterilization to obtain mixed liquor; S2, when the mixed liquor is cooled to pre-set temperature, performing inoculation with a fermenting agent, and performingfermentation under pre-set temperature so as to obtain fermented mulberry juice; and S3, performing homogenizing and refining on the fermented mulberry juice. The reducing sugar comprises but is not limited to one or more of mulberry sugar, galactose, lactose and high fructose corn syrup, and the percentage by mass of the reducing sugar in the mixed liquor is 0.5%-2%; and the fermenting agent comprises but is not limited to probiotics, the addition quantity of the probiotics is 1*10<6> to 1*10<9>cfu / mL, and the fermentation time is 12-96h. The fermented mulberry juice is free from stabilizingagents, stable in system, refreshing in mouth feel, moderate in sour and sweet degrees, delicious, low in slurry stickiness and good in fluidity, and can be directly applied to other products or can be used as ingredients to be applied to the other products; and besides, the making method of the fermented mulberry juice is simple in technology, and is suitable for mass production in factories.

Owner:BRIGHT DAIRY & FOOD CO LTD

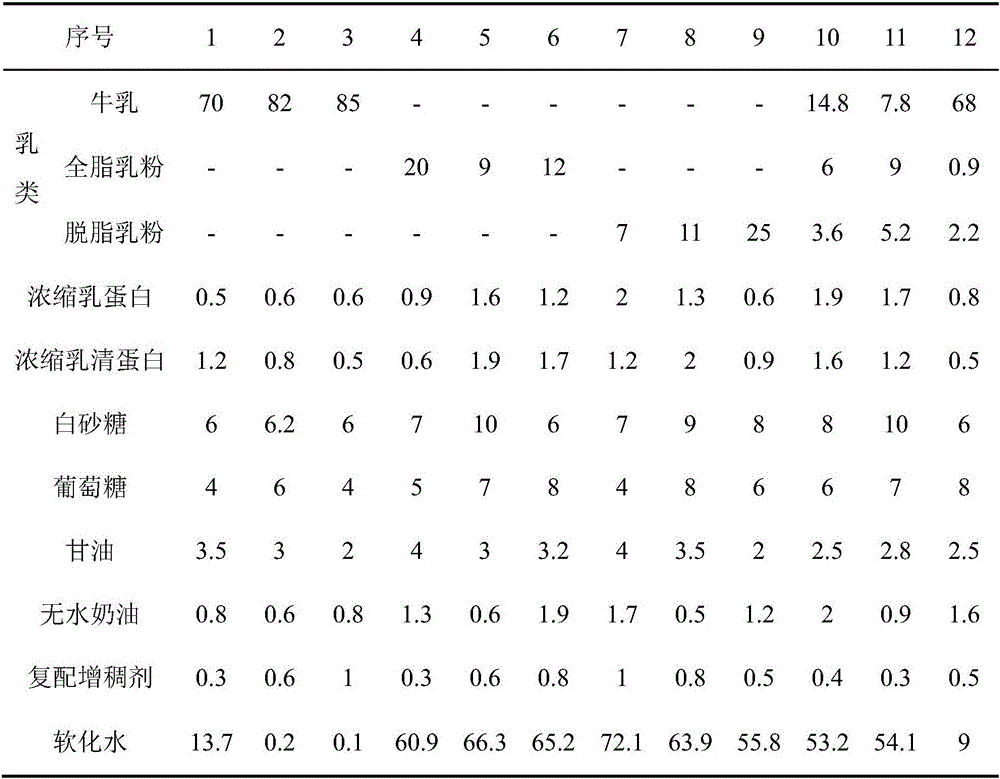

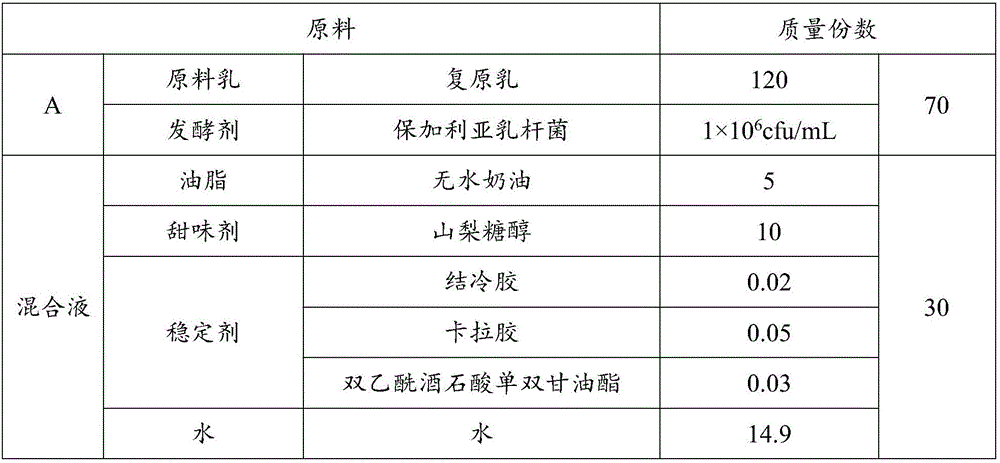

Low-fat frozen yoghurt containing probiotics and preparation method thereof

InactiveCN106615093AReduce intakeExtended shelf lifeMilk preparationFrozen sweetsWhey proteinGlycerol

The invention provides low-fat frozen yoghurt containing probiotics and a preparation method thereof and relates to a formula and a preparation method of low-fat frozen yoghurt containing probiotics. The invention aims at providing frozen yoghurt with low fat content, long guarantee period and high viable content. The low-fat frozen yoghurt containing probiotics is prepared from the following raw materials in parts by weight: lacto-ovo vegetarian, 0.5-2.0 parts of concentrated milk protein, 0.5-2.0 parts of whey protein concentrate, 6-10 parts of white granulated sugar, 4-8 parts of glucose, 2.0-4.0 parts of glycerinum, 0.5-2.0 parts of anhydrous milk fat, 0.3-1 part of a natural mixed thickener and the balance of water replenished until the total weight parts are 100. The preparation method comprises the following steps of: weighing raw materials; mixing protein, milk powder and water; dissolving raw materials; mixing the raw materials and setting the volume; homogenizing; sterilizing; performing incculated fermentation; performing demulsification cooling; performing filling and after-ripening; and freezing a finished product. The fat content of the low-fat frozen yoghurt containing probiotics is reduced from 6.0-8.0% of an existing market product to 2.5-3.0%; furthermore, beneficial probiotics in the yoghurt are reserved, and the guarantee period is prolonged. The preparation method is used in the technical field of dairy processing.

Owner:HEBEI BROS ILONG FOOD TECH LLC

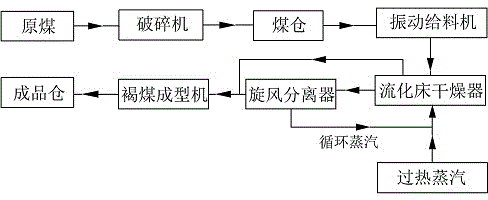

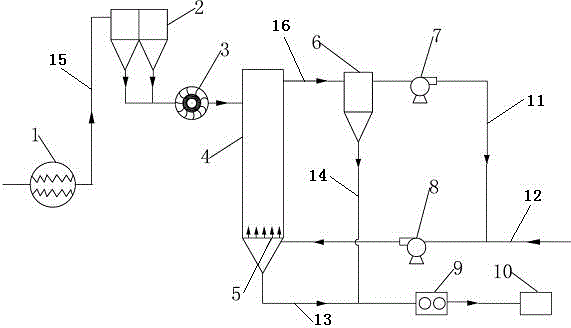

Equipment and process for lignite fluidized bed drying and upgrading

ActiveCN103602360BGuaranteed Granularity RequirementsGuaranteed crushing efficiencySolid fuelsFluidized bed dryingMolding machine

The invention relates to a device for drying and upgrading a lignite fluidized bed and a technology of the device. At present, the same type of device which is high in drying efficiency and high in environment friendliness and a technology of the device do not exist. The device for drying and upgrading the lignite fluidized bed is characterized by comprising a ring hammer type crusher, a cyclone separator, a lignite molding machine, a finished product storehouse, a lignite granule pipe, a lignite powder backflow pipe, a lignite granule conveying belt and a powder-steam conveying pipe, wherein one end of the lignite powder backflow pipe is connected to the bottom of the cyclone separator, and the other end of the lignite powder backflow pipe is connected to the lignite granule pipe; the lignite molding machine and the finished product storehouse are connected with each other through the belt. The technology disclosed by the invention comprises the following steps that (1) raw lignite is conveyed into the ring hammer type crusher for crushing, and the crushed lignite is conveyed into the lignite storehouse through the conveying belt; (2) overheated steam is input into a fluidized bed dryer through an overheated steam pipe; (3) the separated lignite powder is discharged from the bottom of the cyclone separator; (4) the lignite powder is molded under compression of the lignite molding machine to obtain finished lignite products. The device and the technology are high in drying efficiency and high in environment friendliness, and the steam can be recycled.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

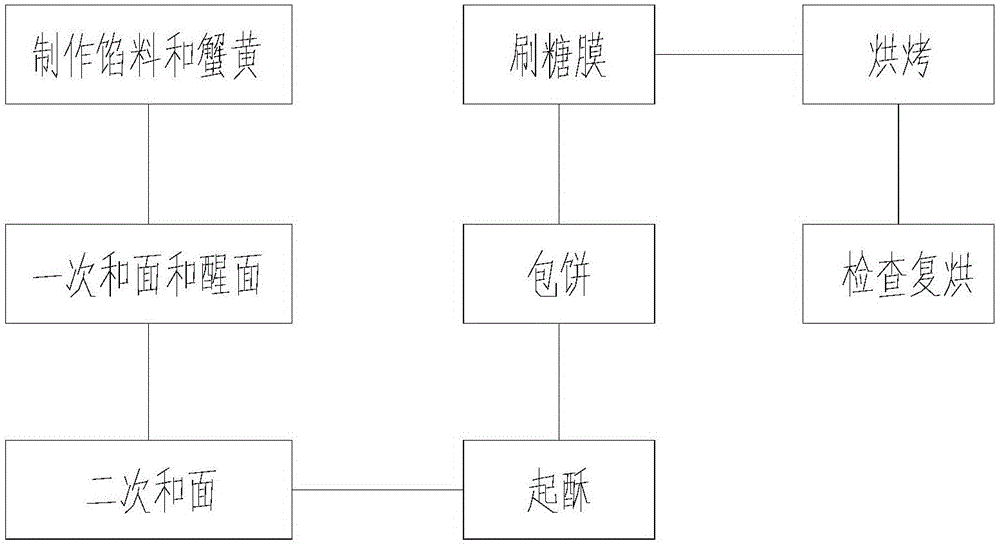

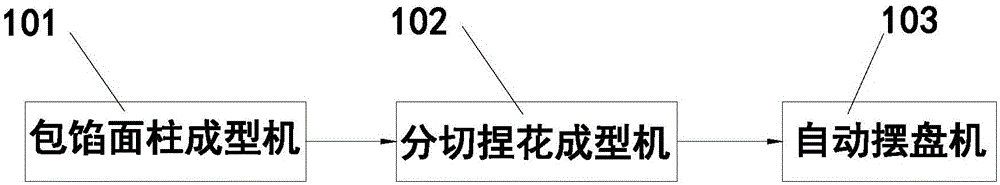

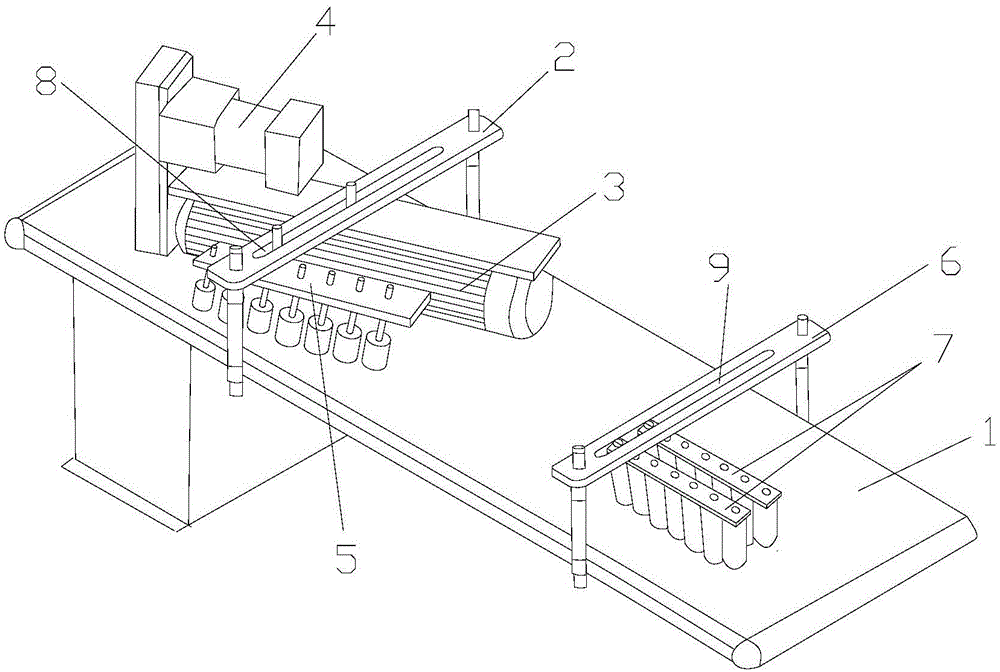

Method for making crabshell yellow sesame seed cake

InactiveCN105145743AReduce distanceAvoid scrappingDough treatmentBakery productsPreservativeEngineering

The invention discloses a method for making a crabshell yellow sesame seed cake. The method includes the seven steps of stuffing and crab cream making, primary dough kneading and leavening, secondary dough kneading and leavening, puffing, cake covering, sugar film brushing and baking. The temperature in a material barrel is controlled in the primary dough kneading and leavening process, the amount of required water is adjusted according to specific seasons, and dough leavening efficiency is greatly improved. Besides, the crisp degree and chewiness of the cake are remarkably improved. The making method is unique and low in cost. No pigment or preservative is added in the making process. The requirements for nutrients, health care and fresh taste of people are met. The bottleneck that standard, industrial and large-scale production of a crabshell yellow sesame seed cake is difficult to achieve is broken through. The cake made through the method is in the color of crab cream, crisp, layering, scorched outside but tender inside, oily but not greasy and popular with mass customers.

Owner:HUANGSHAN HANBAIQI FOOD CO LTD

On-site making and on-site selling system supporting online ordering

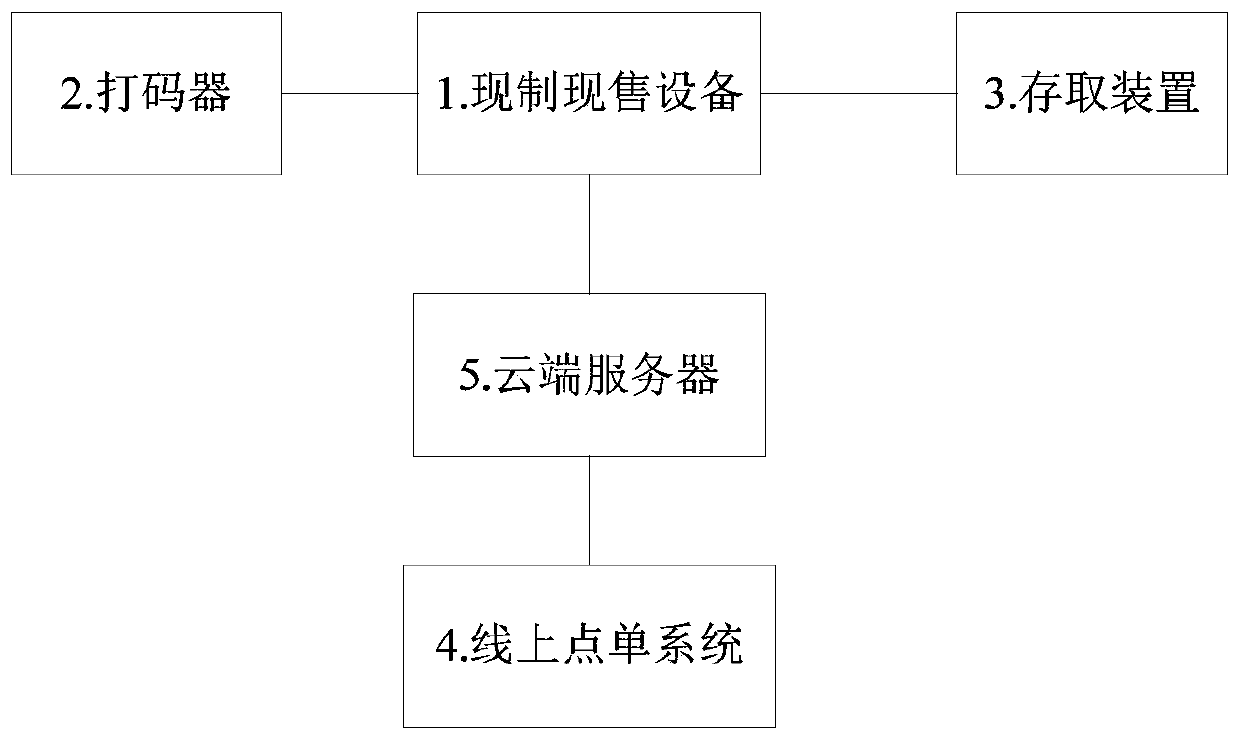

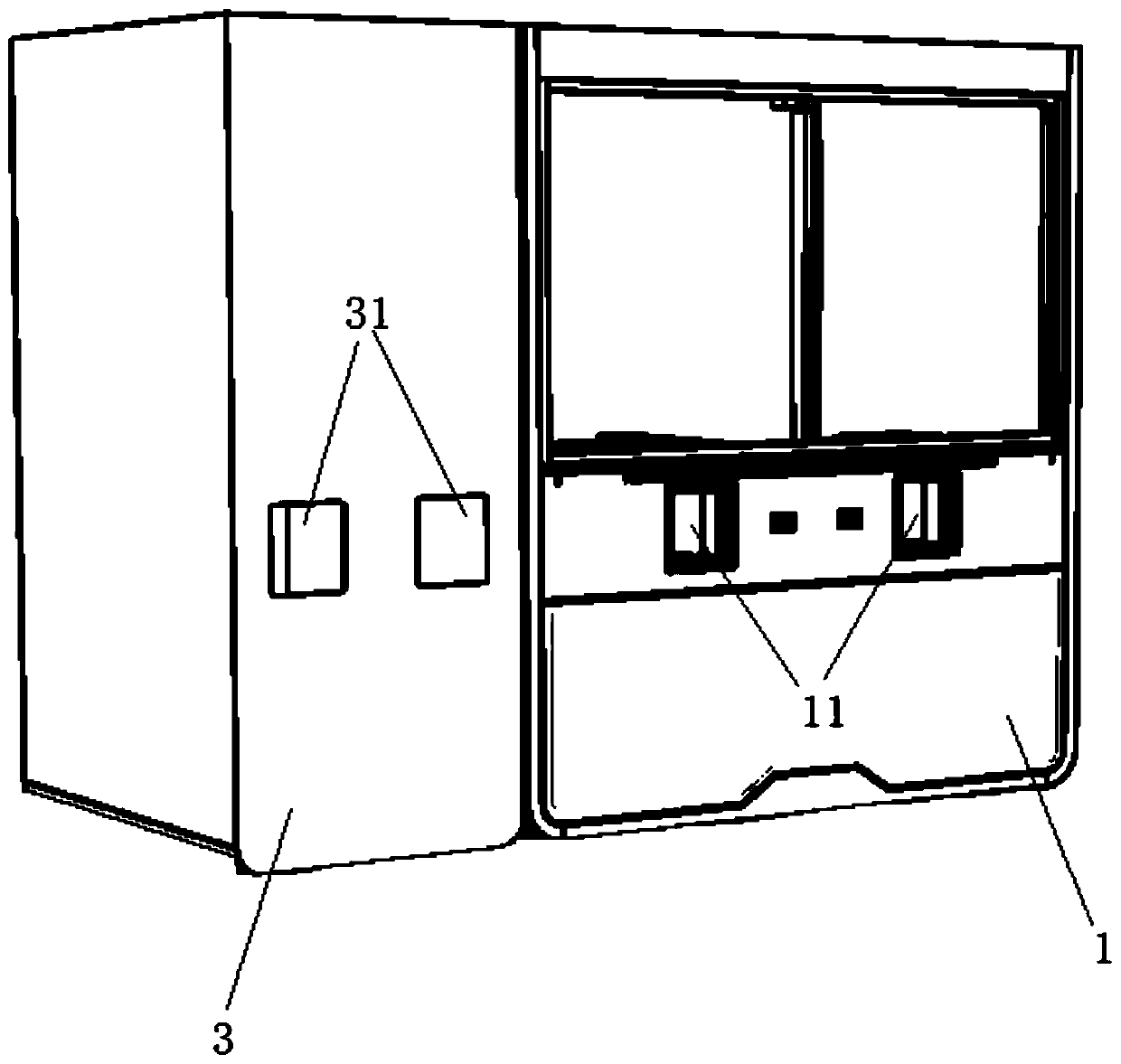

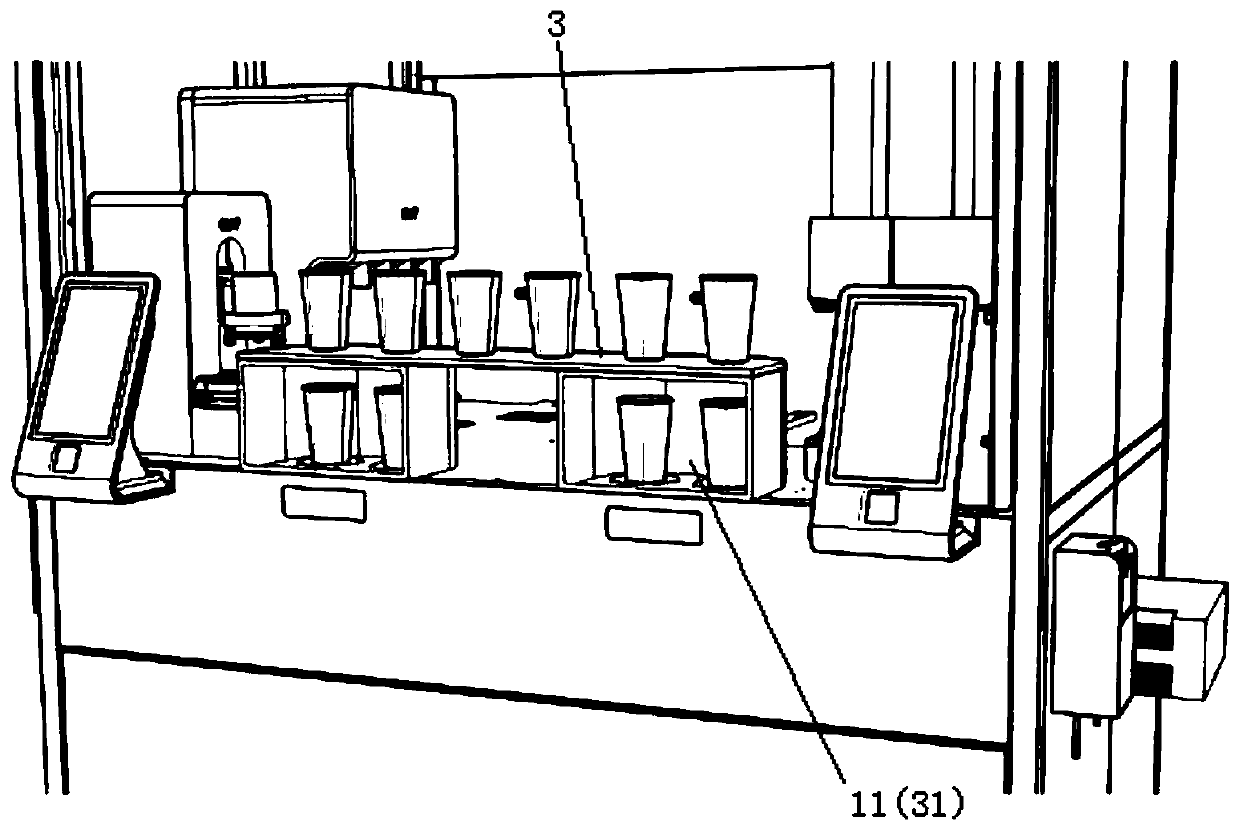

InactiveCN111243182AWith offline orderWith online order functionCo-operative working arrangementsApparatus for meter-controlled dispensingComputer scienceDatabase

The invention discloses an on-site making and on-site selling system supporting online ordering. The on-site making and on-site selling system comprises on-site making and on-site selling equipment, acode printer, a storing and taking device, an online ordering system and a cloud server, the on-site making and on-site selling equipment is used for making food, the code printer prints codes on outer packages of the on-site made food, and 10 or more storage positions are arranged in the storing and taking device and used for storing the on-site made food in a preset number. The on-site making and on-site selling equipment supports offline ordering of the user; the online ordering system is used for a user to order an order online and generate order information and pickup code information associated with the order information and send the order information and the pickup code information to the on-site making and on-site selling equipment through the cloud server, so that the on-site making and on-site selling equipment makes corresponding on-site made food according to the order information, and an user for online ordering takes the on-site made food according to the pickup code information. The sales mode of the on-site selling equipment is expanded, and it is ensured that online ordering and offline ordering do not conflict with each other during goods taking.

Owner:SHANGHAI HI DOLPHIN ROBTICS CO LTD

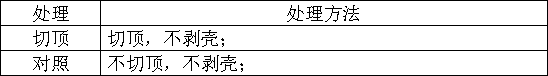

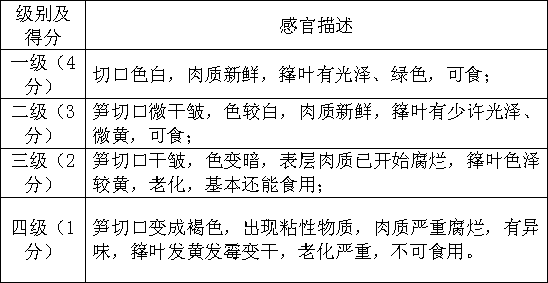

Fresh keeping method of bambusa oldhami

InactiveCN108157491AImprove storage effectDelayed storage effectFruits/vegetable preservation by freezing/coolingCelluloseFlavor

The invention relates to a fresh keeping method of bambusa oldhami. Growing points of tender tips of bamboo shoots are cut off through a physical means, so that physiological activity and generation of endogenous hormones of the bambusa oldhami are restrained to a certain extent; and through cooperation with precooling treatment before cutting off the growing points of tender tips of bamboo shoots, the storage effect of the bambusa oldhami after the growing points of tender tips of bamboo shoots are cut off is increased, the formation of lignin, cellulose and the like is reduced, and the ageing speed of the bambusa oldhami is reduced, so that the purpose of fresh keeping of the bambusa oldhami is realized. According to the fresh keeping method disclosed by the invention, the ageing speed of the bambusa oldhami can be effectively delayed, the storage time of the bambusa oldhami is prolonged, the flavor, the mouth feel and the nutrient value of the bambusa oldhami are effectively maintained, the sell range can be enlarged, and the economic benefits can be increased. The treated bambusa oldhami can be stored for 20d, the edible rate can reach 60% or above, and the sense organ change is small; and the protein is obviously reduced after the bambusa oldhami is stored for 10 d, PAL activity, POD activity and PPO activity are obviously restrained within the storage period of 3-10d, andthe fresh keeping method has obvious fresh keeping effect on the bambusa oldhami.

Owner:ZHEJIANG SUB TROPICS CROP INST

Functionality beverage containing burdock and preparation method thereof

InactiveCN101283822AIncrease contentUnique formulaMetabolism disorderDigestive systemNutrientEquivalent function

The invention relates to a functional beverage containing Fructus arctii. The functional beverage is prepared from Fructus arctii with homogenous function on medicines and food as the main material, and vegetables such as carrots, white radishes and shiitake. The functional beverage of the invention has higher content of nutriment on the basis that the beverage has equivalent function of prior beverage containing Fructus arctii. The invention also relates to the preparation method of the functional beverage containing Fructus arctii. Compared with prior art, the method is more suitable for industrial production and has lower production cost.

Owner:史发臣

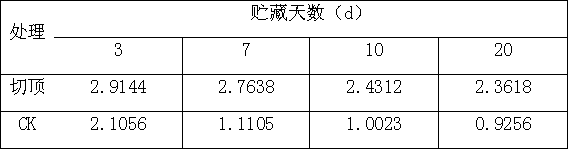

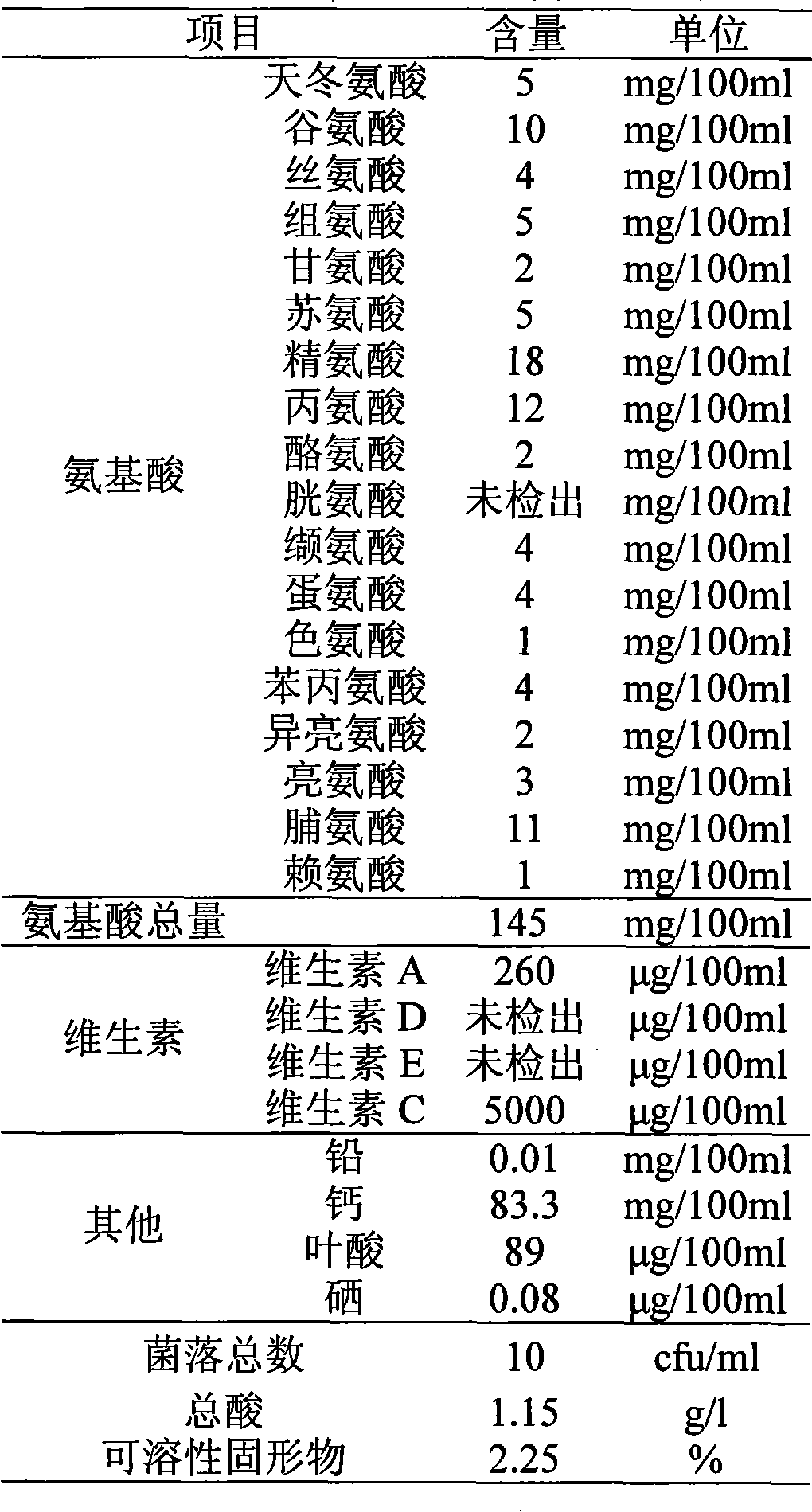

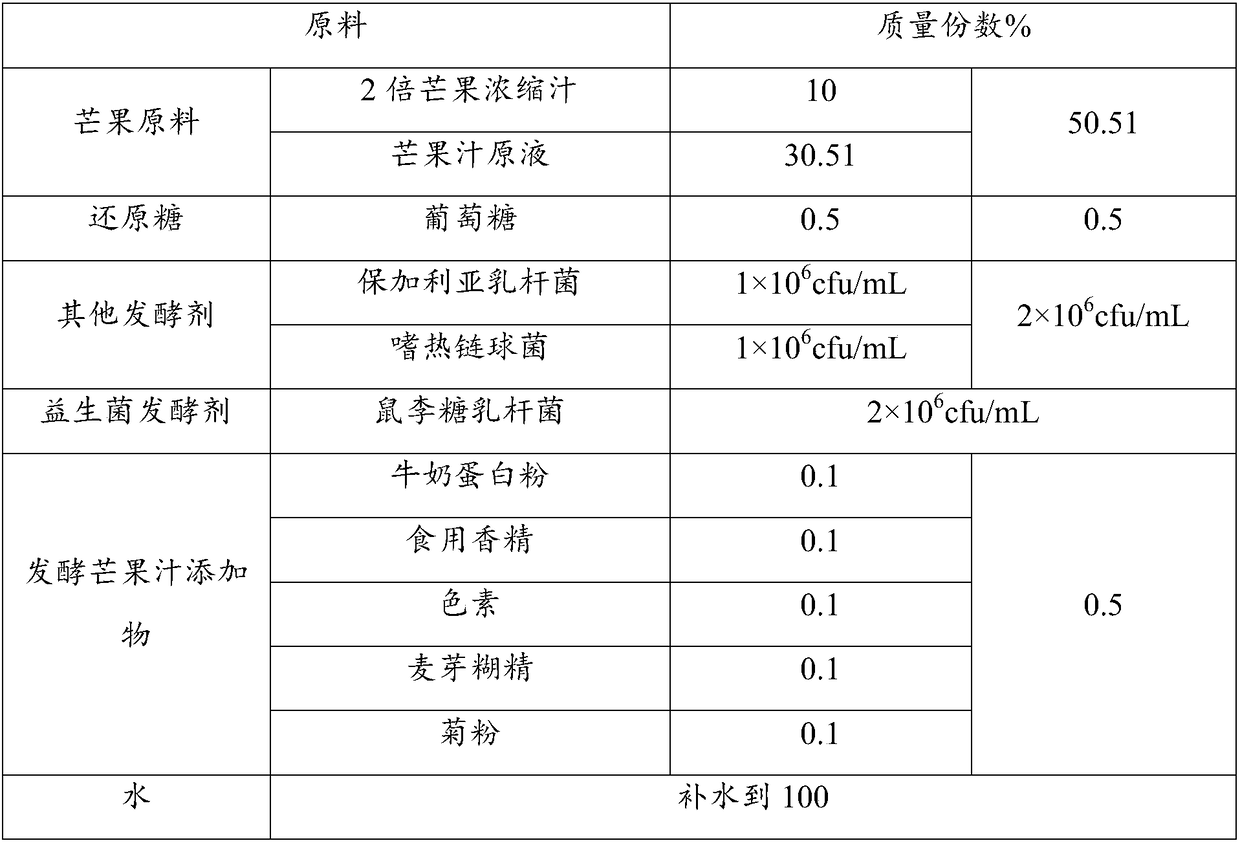

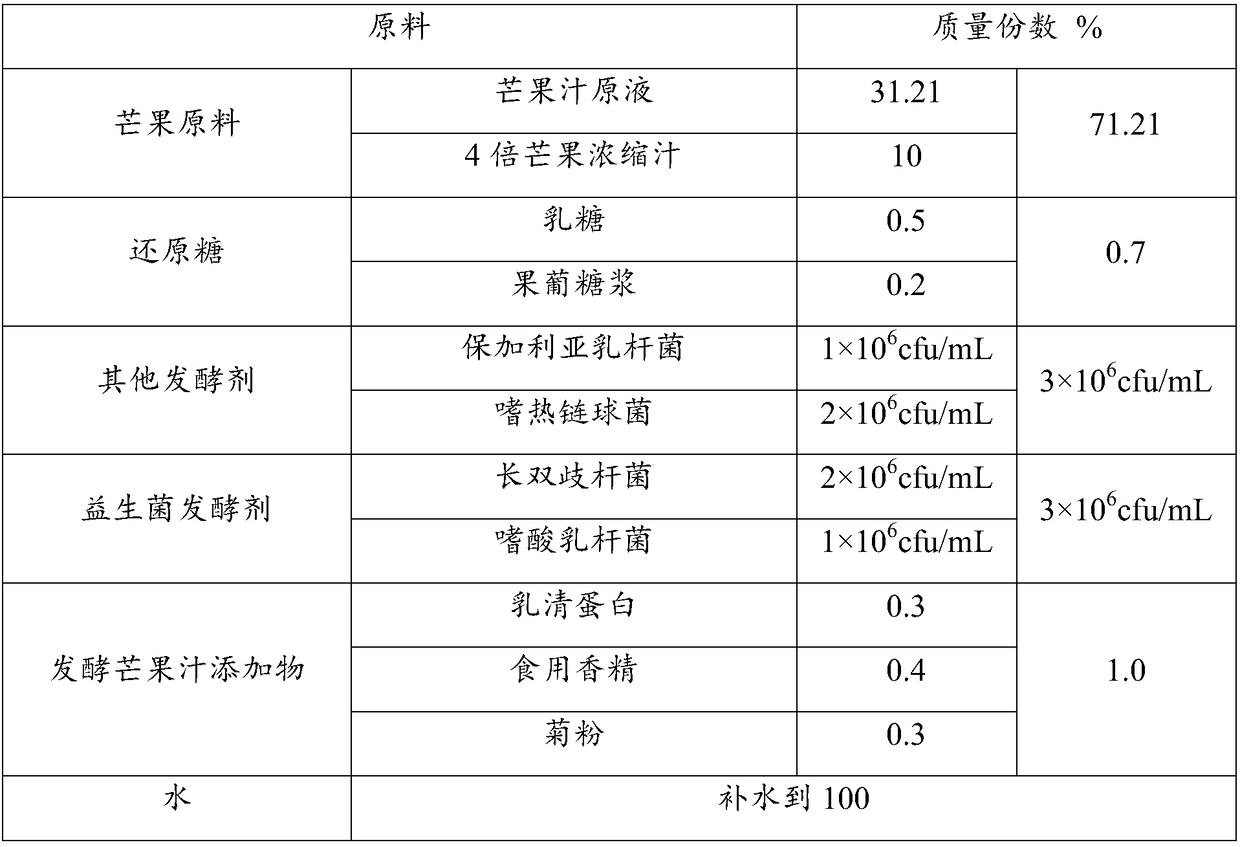

Fermented mango juice and preparation method thereof

The invention discloses fermented mango juice and a preparation method thereof. The preparation method comprises the following steps: S1: uniformly mixing a mango raw material juice, reducing sugar and water, and performing filtering and sterilization, so as to obtain a mixed solution; S2: inoculating a leavening agent when the mixed solution is cooled to a preset temperature, and performing fermentation at the preset temperature, so as to obtain the fermented mango juice; S3: performing homogeneous refinement on the fermented mango juice. The reducing sugar comprises, but not limited to, oneor more of glucose, galactose, lactose and fructose corn syrup, and the mixed solution contains 0.5 to 2 mass percent of the reducing sugar; the leavening agent comprises, but not limited to, probiotics; the adding amount of the probiotics is 1 x 10<6> to 1 x 10<9> cfu / mL, and the fermentation time is 12 to 96 hours. The fermented mango juice does not contain a stabilizer, is stable in system, tastes refreshing, sour, sweet and delicious, low in slurry viscosity and high in flowability, can be directly applied to other products or used as an ingredient applied to other products. Furthermore, the preparation method of the fermented mango juice is simple in process and suitable for industrial large-scale production.

Owner:BRIGHT DAIRY & FOOD

Toughened tile-like coating

The invention discloses a toughened tile-like coating, which comprises the following main components in part by weight: 6 to 10 parts of methylcellulose, 50 to 80 parts of polyvinyl acetate emulsion, 250 to 320 parts of calcium hydroxide powder, 250 to 320 parts of calcite powder, 1 to 3 parts of pigment, 0.05 to 0.5 part of antifoaming agent and the balance of water. A preparation method comprises the following steps of: adding water in an amount which is two times that of the polyvinyl acetate emulsion into the polyvinyl acetate emulsion for diluting; adding the methylcellulose into the residual water, dissolving for 24 to 48 hours, dispersing, and standing for later use; adding the two kinds of solution into a dispersion machine for mixing, adding the pigment and the antifoaming agent,and dispersing; and adding the calcium hydroxide powder and the calcite powder, uniformly dispersing, and grinding to prepare the tile-like coating. The coating does not crack, and has water scrubbing resistance which can reach the national standard of an outer wall coating; and the coating has the advantages of smooth, firm and durable surface, water and fire resistance, low cost, long storage period and the like, and is easy to transport remotely.

Owner:梁振华

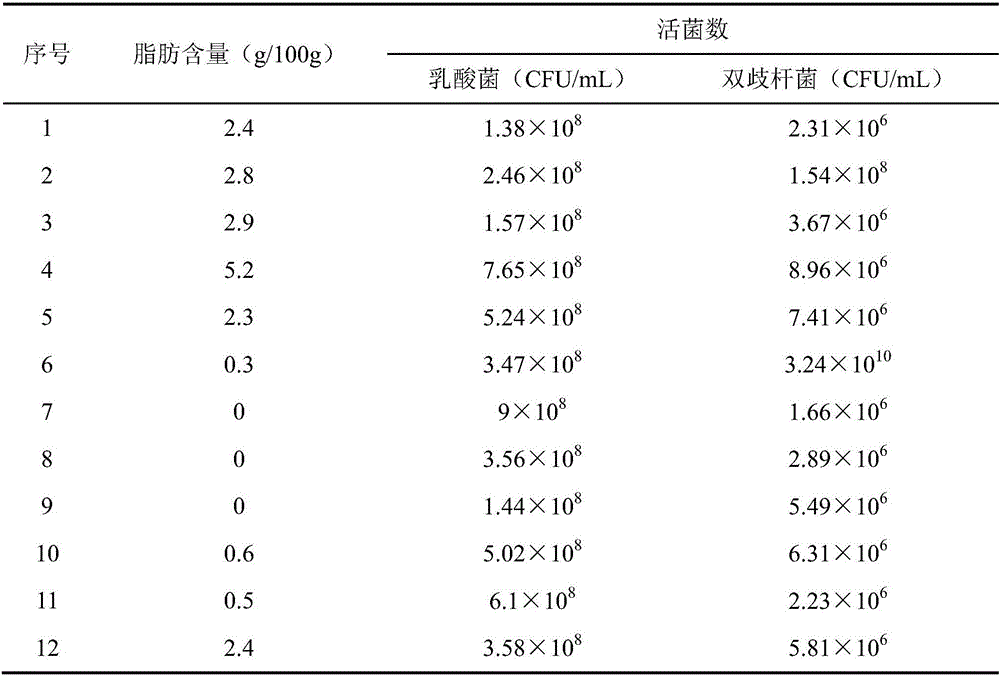

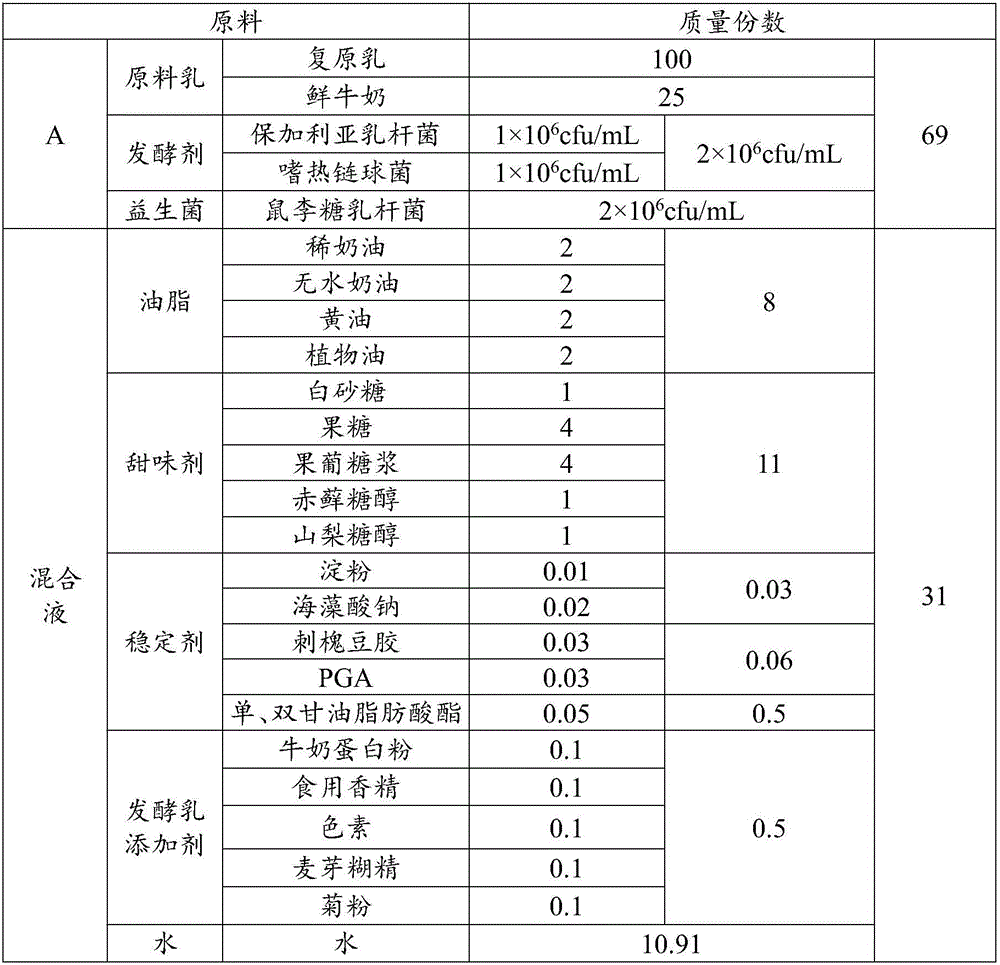

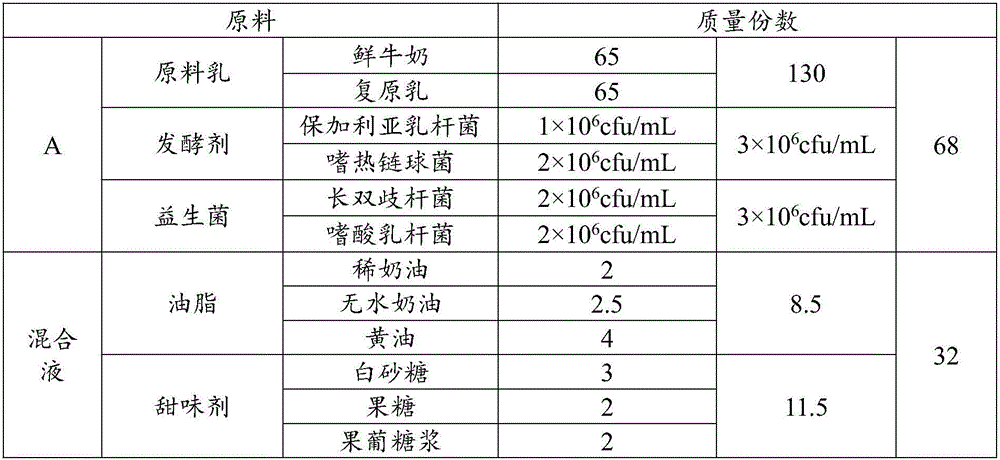

Fermented milk for ice cream and preparation method of fermented milk

InactiveCN106615098AExtended shelf lifeExpand sales radiusMilk preparationOil and greaseMicroorganism

The invention discloses a preparation method of fermented milk for ice cream. The preparation method comprises the following steps of (a) concentrating 120-165 parts by mass of raw milk, performing homogenizing, and performing sterilization so as to obtain 60-70 parts by mass of concentrated milk; (b) cooling the concentrated milk, adding a fermenting agent, performing fermentation, and performing cooling so as to obtain a fermented base material A; (c), uniformly mixing a raw material B with water, wherein the raw material B comprises 5-15 parts by mass of oil, 0.1-1 part by mass of a stabilizing agent and 10-15 parts by mass of a sweetening agent, performing sterilization, and performing cooling so as to obtain mixed liquor; (d) uniformly mixing the fermented base material A with the mixed liquor so as to obtain fermented milk; and (e) performing frozen preservation on the fermented milk, wherein the sum of the parts by mass of the concentrated milk and the parts by mass of the mixed liquor in the step (c) is 100 parts by mass. Through the adoption of the preparation method of adopting the raw materials in a certain compounding ratio and compounding materials twice, the real fermented milk for the ice cream, which can be stored for a long term, is obtained, the quality guarantee period of the fermented milk can be as long as 24 months, viable bacteria can be maintained to be 10<7>cfu / g or above, the stability and the microorganism indexes of the fermented milk are excellent, the quality guarantee period of the fermented milk is greatly prolonged, and the sale radius of the fermented milk for the ice cream is enlarged.

Owner:BRIGHT DAIRY & FOOD

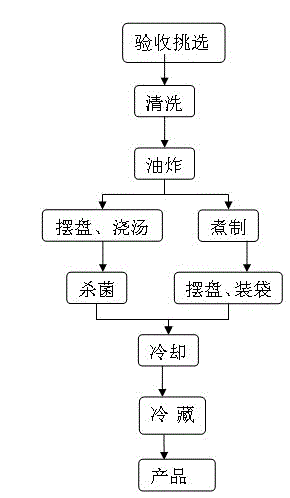

Processing method of instant refrigerated cooked red swamp crawfish

The invention discloses a processing method of instant refrigerated cooked red swamp crawfish and provides an industrized production method of cooked red swamp crawfish, belonging to the technical field of aquatic product processing in food processing and storing. In the invention, fresh red swamp crawfish is used as the raw material to be prepared into a cooked red swamp crawfish product capableof being stored at 0-10 DEG C through checking, picking up, cleaning, frying, boiling or not boiling, laying on a disk, pouring sauce, sealing, sterilizing, cooling and refrigerating. The red swamp crawfish product prepared by using the method provided by the invention completely remains the original flavor, texture, color, luster and nutrition of the red swamp crawfish, has no addition of any chemical preservative in the processing process and is safety in eating. In addition, the instant refrigerated cooked red swamp crawfish can be eaten by simply heating, thereby being convenient to eat and meeting the requirement of modern consumers for nutritious and delicious foods and quick rhythm life.

Owner:JIANGNAN UNIV

Method for preserving cordate houttuynia by using gas packing

InactiveCN103431034AExpand sales radiusSimple preservation methodFruits/vegetable preservation by freezing/coolingAgricultural engineeringHouttuynia

The invention discloses a cordate houttuynia preservation method, in particular relates to a method for preserving cordate houttuynia by using gas packing, belonging to the technical field of agricultural food science. The method aims at the characteristics that cordate houttuynia is subjected to brown stain easily, and the brittleness of the cordate houttuynia is reduced in the cordate houttuynia storage process, and can achieve the preservation by using the gas packing method. The method comprises the steps of cleaning the cordate houttuynia, blowing away part of waste heat, pre-cooling, then placing the cordate houttuynia into ethylene / ethylene vinyl alcohol copolymer freshness protection bags, filling a gas formed by mixing CO2, N2 and O2, carrying out heat sealing, and placing the cordate houttuynia in a refrigeration house being 2+ / -1 DEG C for storage. The mixed gas comprises the gases of 20-30% of the CO2, 5-10% of the O2 and the balance being the N2 according to the volume rate. The retain freshness gas mixing accuracy error rate is less than 1.5%; the cordate houttuynia can be stored for 30 days; the edible rate of the cordate houttuynia is more than or equal to 85%.

Owner:GUIYANG UNIV

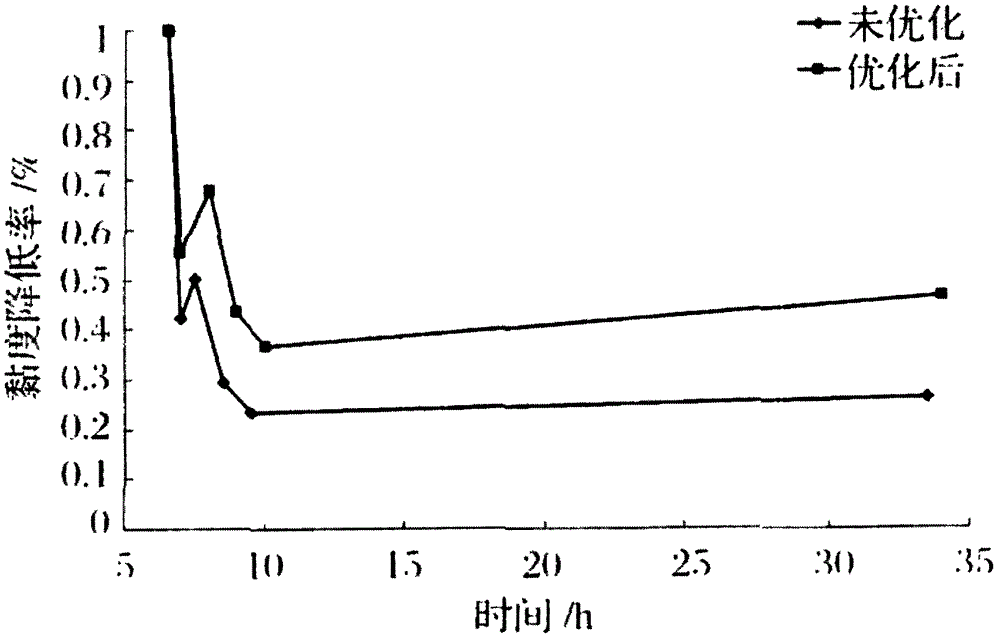

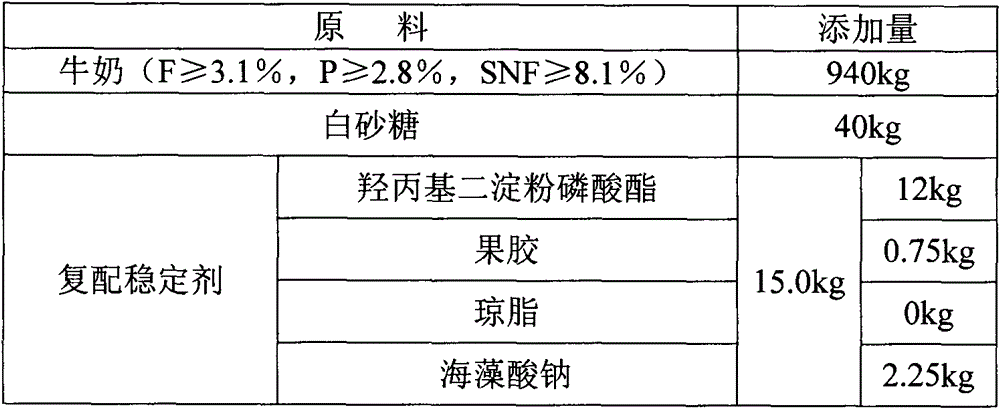

Compound stabilizing agent, fermented yogurt comprising compound stabilizing agent, and preparation method of fermented yogurt

ActiveCN103081995BImprove shear resistanceAchieve room temperature salesMilk preparationCold chainPasteurization

The invention discloses a compound stabilizing agent, a fermented yogurt comprising the compound stabilizing agent, and a preparation method of the fermented yogurt. The compound stabilizing agent provided by the invention comprises esterified starch, pectin, sodium alginate, agar, xanthan gum, and gelatin. The viscosity of the sodium alginate is 500mPa.s-1000mPa.s. The preparation method provided by the invention comprises the steps that: (1) the compound stabilizing agent provided by the invention, a sweetening agent, water, and pre-sterilized and preheated nonreactive milk are uniformly mixed; (2) homogenization is carried out; (3) pasteurization is carried out; (4) cooling is carried out, and a fermentation agent is added and fermentation is carried out; (5) jar turning is carried out; (6) pasteurization is carried out; and (7) rapid cooling is carried out, and sterile preservation is carried out. With the twice pasteurization technology and the sterile filling technology, physical and chemical stability and hygienic index stability of the fermented yogurt can be maintained after 3-6 months of storage under a normal temperature of 20-40 DEG C. Therefore, normal-temperature selling of fermented yogurt with a protein content no lower than 2.3% is realized, and the problem of long-distance selling of fermented yogurt due to cold chain restriction is solved.

Owner:BRIGHT DAIRY & FOOD CO LTD

A kind of processing method of ready-to-eat refrigerated delicious crayfish

ActiveCN105942305BExcellent organization and flavorExpand sales radiusFood scienceFlavorChemical preservatives

The invention discloses a processing method for instant refrigerated delicious crayfishes. The processing method includes the steps that alive freshwater crayfishes are used as the raw material, and a cooked freshwater crayfish product capable of being preserved at the temperature of 0-10 DEG C is prepared through checking, picking, cleaning, cooking, bagging, vacuum packaging, cooling and refrigerating. The shelf life of the refrigerated food is 15-30 days, no chemical preservative is added in the processing process, original flavor, texture, color and nutrition of the freshwater crayfishes are retained, people can eat the instant refrigerated delicious crayfishes conveniently just by opening a package bag, and the requirement for food nutrition, delicacy and rapid-pace life of consumers is met.

Owner:JIANGNAN UNIV

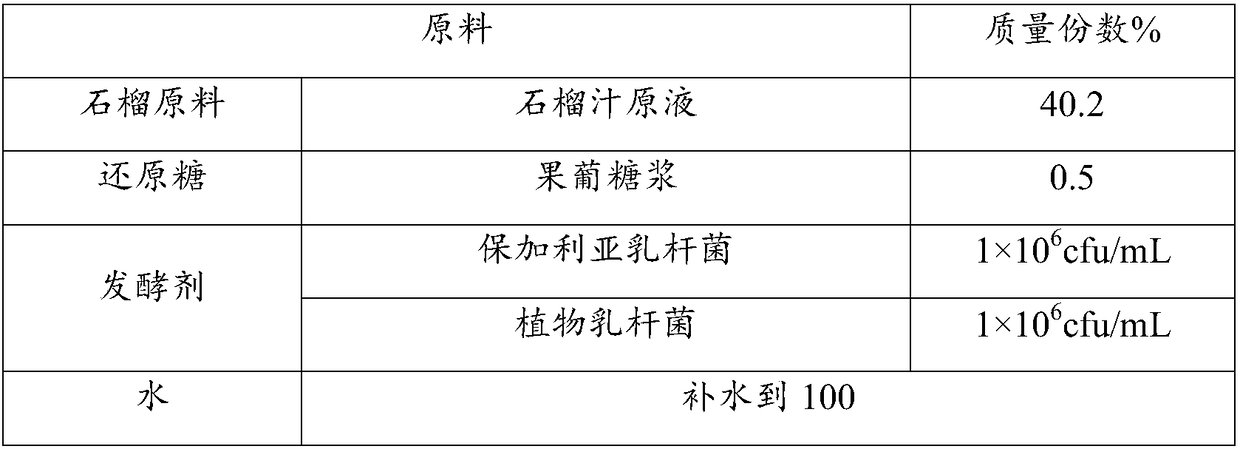

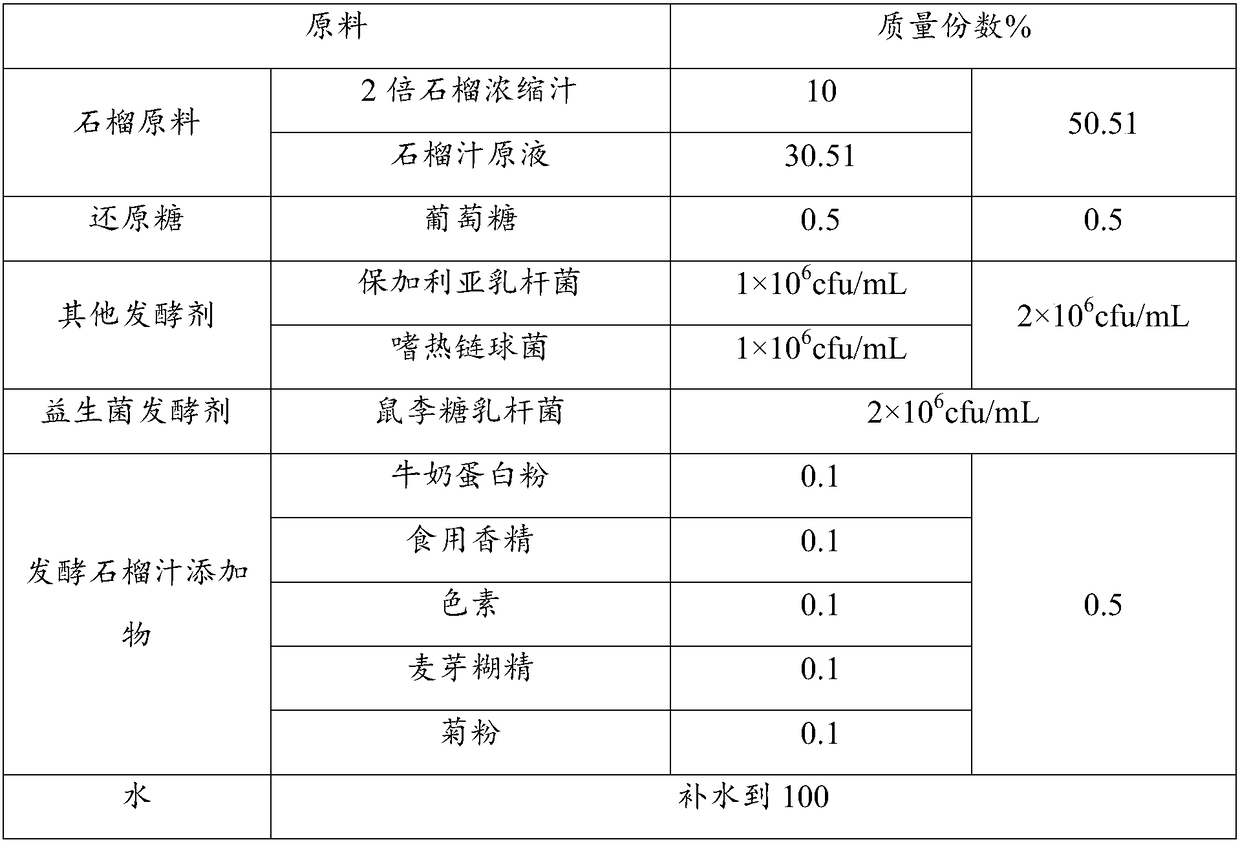

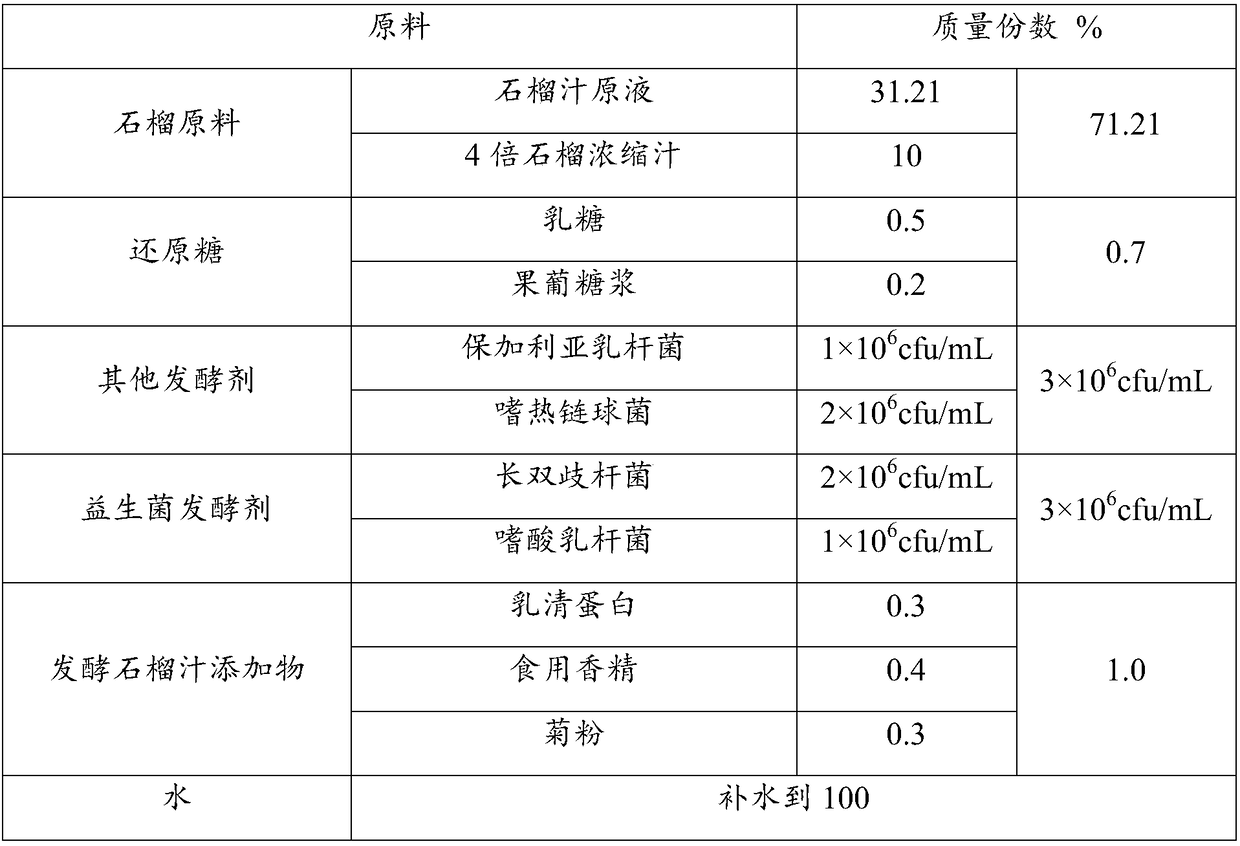

Fermented pomegranate juice and making method thereof

InactiveCN108157712ASuitable for mass productionReduce processSugar food ingredientsFood ingredient functionsHigh-fructose corn syrupSlurry

The invention discloses fermented pomegranate juice and a making method thereof. The making method comprises the following steps of S1, uniformly mixing pomegranate raw juice with reducing sugar and water, and performing filtering and sterilizing to obtain mixed liquid; S2, when the mixed liquid is cooled to preset temperature, performing inoculating with a fermenting agent, and performing fermentation under the preset temperature to obtain the fermented pomegranate juice; and S3, homogenizing the fermented pomegranate juice and performing fining. The reducing sugar comprises but is not limited by one or more of glucose, galactose, lactose and high fructose corn syrup, and the percentage by mass of the reducing sugar in the mixed liquid is 0.5-2%; and the fermenting agent comprises but isnot limited to probiotics, the addition quantity of the probiotics is 1* 10<6> to 1* 10<9>cfu / mL, and the fermenting time is 12-96h. The fermented pomegranate juice is free from stabilizing agents, stable in system, refreshing in mouth feel, moderate in sour and sweet degrees, delicious, low in slurry stickiness and good in fluidity, and can be directly applied to other products or used as components to be used for other products. The making method of the fermented pomegranate juice is simple, and is suitable for plant mass production.

Owner:BRIGHT DAIRY & FOOD

Functional filling bean curd and preparation method thereof

InactiveCN102687764BHigh nutritional valueImprove food valueCheese manufactureFood scienceBiotechnologyPearl barley

The invention discloses functional filling bean curd and a preparation method thereof, belonging to the field of foods and a food processing technology. L-lactic acid produced by the probiotics LGG lactic acid fermentation soymilk is used as a natural coagulator. Chitosan is used for assisting in coagulation, and carrageenan is used as a quality improver. The chitosan and the carrageenan are added in pearl barley soymilk liquid according to proportion, and the mixture is processed into form bean curd. The pearl barley soymilk liquid refers to slurry obtained by adding water into pearl barley powder and soaked soybean, grinding and then filtering, and the slurry is called the pearl barley soymilk liquid for short. The weight ratio of the pearl barley powder to the soybean is (4-6):100; theweight of the water added to the soaked soybean for grinding is 5-7 times that of the soybean; and 5-7g / L carrageenan, 2-3g / L chitosan and 98-105g / L L-lactic acid coagulator are added to the pearl barley soymilk liquid. According to the method disclosed by the invention, standard and industrial production can be realized; and the product has uniform color, appropriate hardness, delicate texture, rich soybean aroma and mellow pearl barley smell, and can not be collapsed after being cut.

Owner:GUIZHOU UNIV

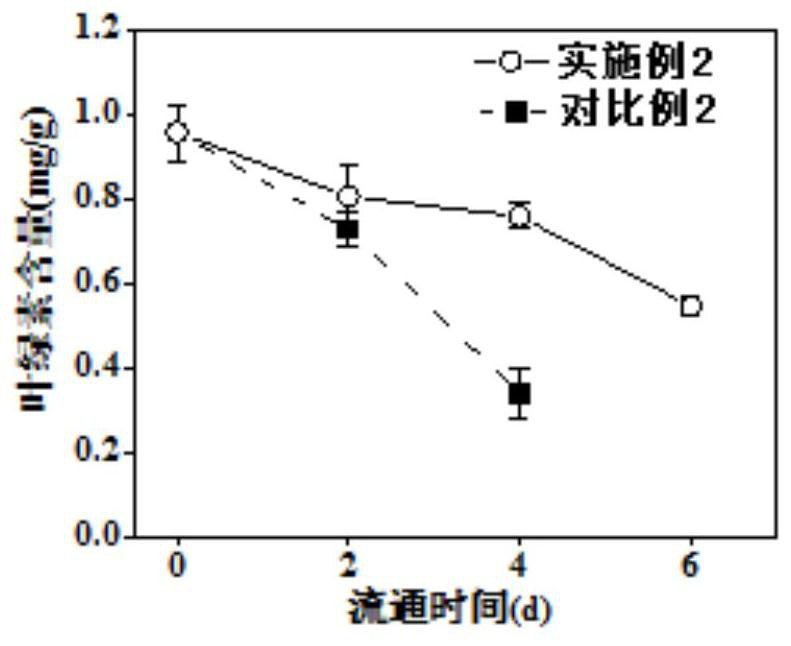

A fresh-keeping method for broccoli sold by e-commerce

ActiveCN108064928BExtend freshnessEasy to operateFruit and vegetables preservationGaseous food ingredientsBroccoli raabEconomic benefits

The invention provides a fresh-keeping method for broccoli sold by e-commerce, which is characterized in that it comprises the following steps: spraying the broccoli with a benzyl adenine solution of 20-40 mg / L concentration 6-10 hours before harvesting; Broccoli is independently packaged with a fresh-keeping bag; ethylene absorbent is placed in the above-mentioned fresh-keeping bag; O is passed into the above-mentioned fresh-keeping bag. 2 and CO 2 Gas, then seal the fresh-keeping bag; put the sealed fresh-keeping bag into the foam box. The technical solution provided by the invention is simple in operation and low in cost, and is favorable for popularization and application. By prolonging the preservation time of broccoli during transportation, the purpose of prolonging sales radius and balancing market supply can be achieved, thereby effectively improving economic benefits.

Owner:JIANGSU ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com