Fermented milk for ice cream and preparation method of fermented milk

A technology of fermented milk and ice cream, which is applied in the field of fermented milk, can solve the problems of limited service time and achieve the effects of no oil-water separation, extended shelf life, and stable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Therefore, through creative work, the inventor, in a specific embodiment, proposes a method for preparing fermented milk for ice cream, comprising the following steps: (a) 120-165 parts of raw milk are concentrated, homogenized, and sterilized to obtain 60 -70 parts of concentrated milk; (b) cooling the concentrated milk, adding a starter, fermenting, and cooling to obtain a fermented base material A; (c) raw material B including 5-15 parts of oil, 0.1-1 part of a stabilizer and a sweetener 10-15 parts, mixing raw material B and water, sterilizing, cooling to obtain a mixed solution; (d) mixing the fermentation base material A with the mixed solution to obtain fermented milk; (e) freezing the above fermented milk. The above-mentioned parts are parts by mass; the sum of the parts by mass of the concentrated milk and the mixed solution in step (c) is 100 parts.

[0028] The above-mentioned raw material milk, oil, stabilizer and sweetener are all technical terms in this fi...

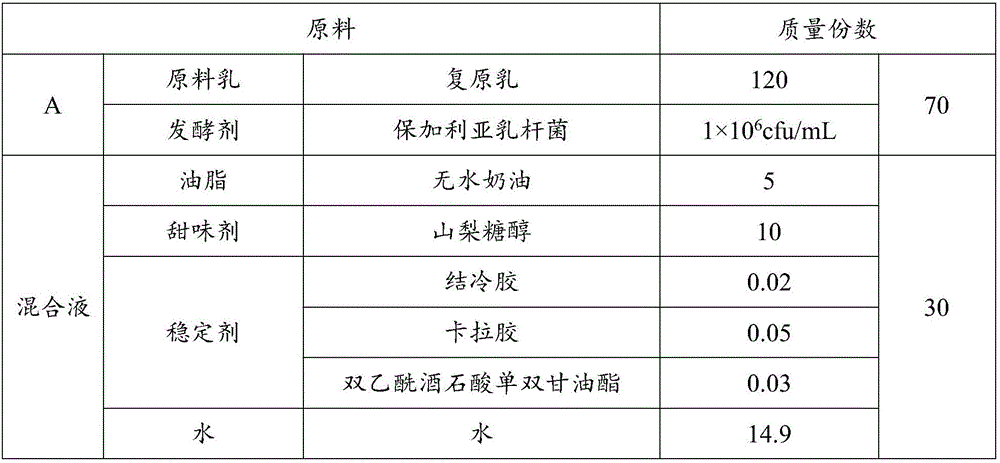

Embodiment 1

[0065] 1. Proportion

[0066] Table 1

[0067]

[0068] 2. Method

[0069] (1) According to the ratio in Table 1, the raw milk was concentrated, subjected to 15Mpa, 54°C primary homogenization, and 90°C sterilization for 5 minutes to obtain 70 parts of concentrated milk.

[0070] (2) After the concentrated milk is cooled to 37°C, add starter, and ferment at 37°C. After 6 hours, the acidity reaches 100°T, and the fermentation is stopped; second cooling to 2°C yields fermentation base material A, which is stored for later use.

[0071] (3) Stir and mix the oil, sweetener, stabilizer and water at 60°C for 10 minutes, sterilize at 90°C for 5 minutes, and then cool to 2°C to obtain a mixed liquid.

[0072] (4) Mix the fermented base material A with the mixed solution to obtain fermented milk. The fermented milk is refined with an emulsifier, frozen at -70°C for 0.1 hour after filling, and then transferred to -20°C for storage and transportation.

[0073] After testing, 24 mo...

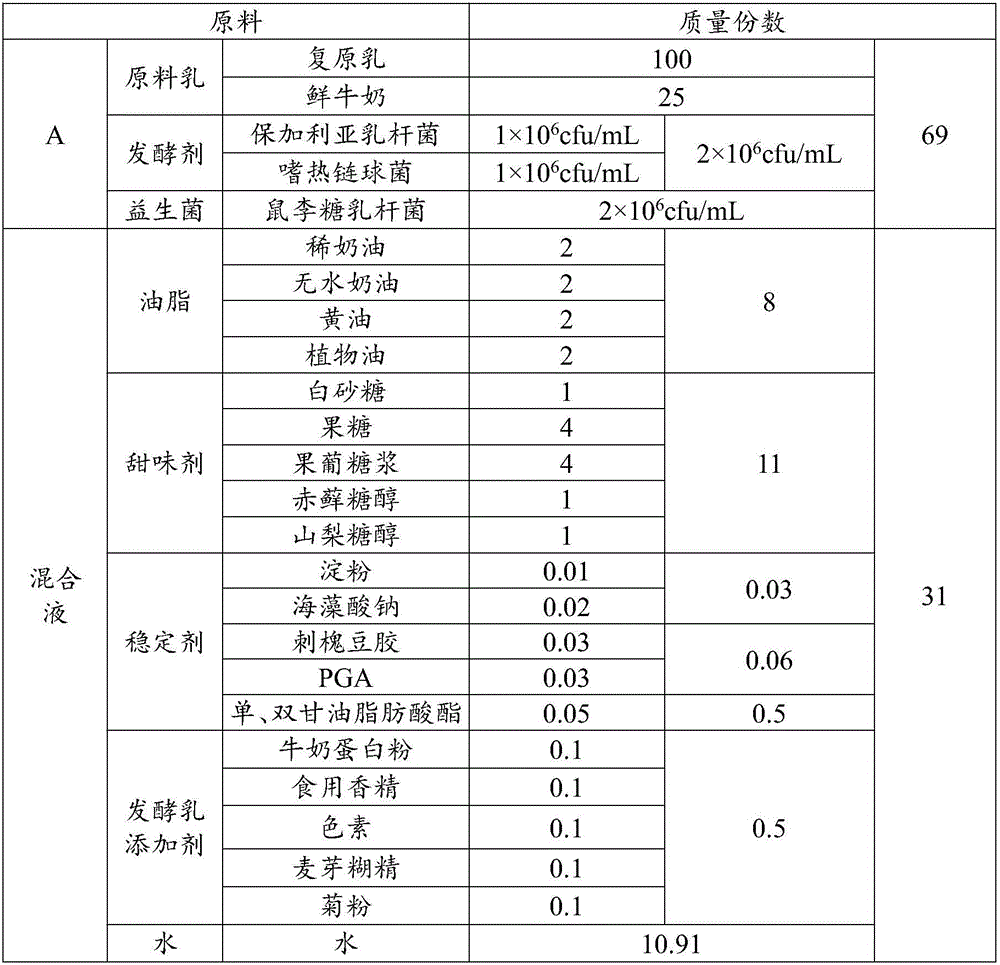

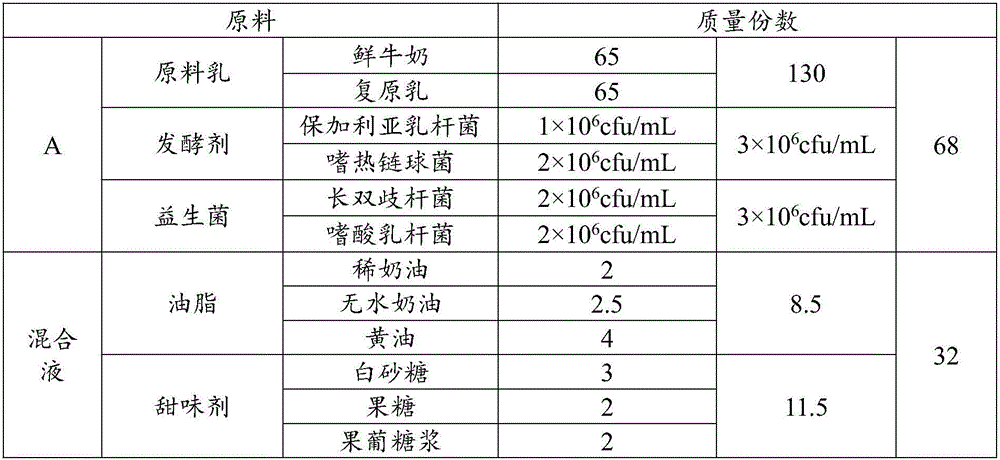

Embodiment 2

[0075] 1. Proportion

[0076] Table 2

[0077]

[0078] 2. Method

[0079] (1) According to the ratio in Table 2, the raw milk was concentrated, subjected to 16Mpa, 55°C primary homogenization, and 91°C sterilization for 5 minutes to obtain 69 parts of concentrated milk.

[0080] (2) After the concentrated milk is cooled to 38°C, add starter and probiotics, and ferment at 38°C. After 6.4 hours, the acidity reaches 113°T, and the fermentation is stopped; after cooling to 5°C for the second time, fermentation base A is obtained and stored spare.

[0081] (3) Stir and mix the oil, sweetener, stabilizer, fermented milk additive and water at 62°C for 14 minutes, sterilize at 91°C for 5 minutes, and then cool to 5°C to obtain a mixed solution.

[0082] (4) Mix the fermented base material A with the mixed solution to obtain fermented milk. The fermented milk is first-level homogenized at 15Mpa, frozen at -50°C for 0.2 hours after filling, and then transferred to -25°C for stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com