Low-fat frozen yoghurt containing probiotics and preparation method thereof

A technology of frozen yogurt and probiotics, applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of restricting the production and sales of yogurt, restricting sales channels and sales scope, and not being able to adapt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The low-fat probiotic frozen yoghurt of the present embodiment is prepared according to the following steps:

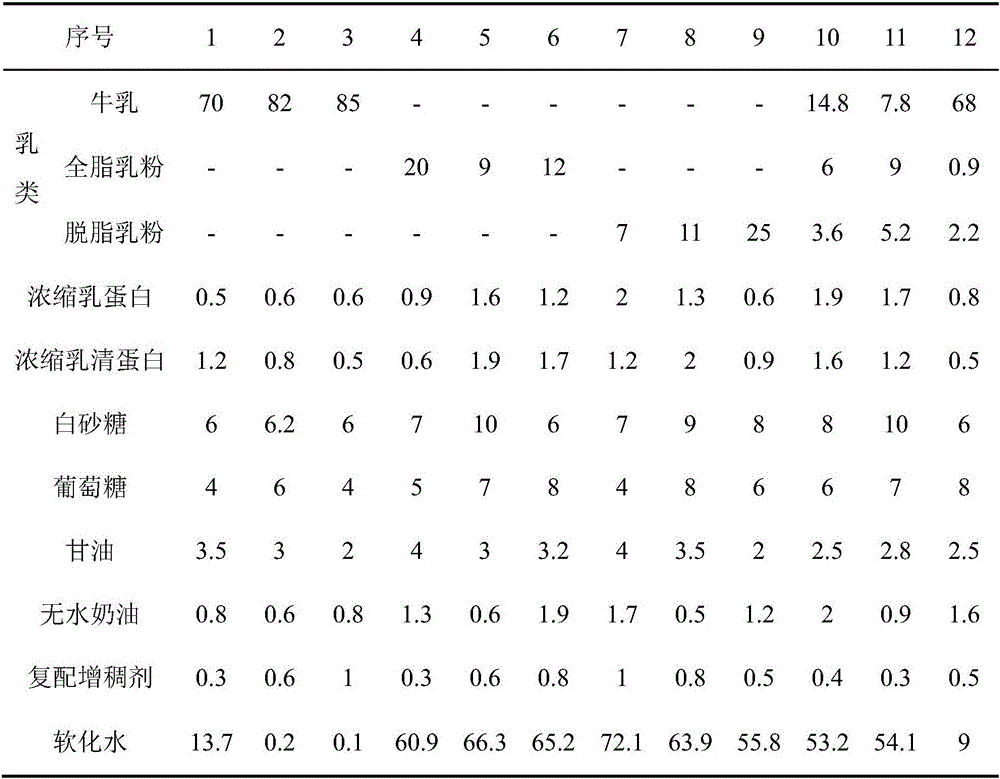

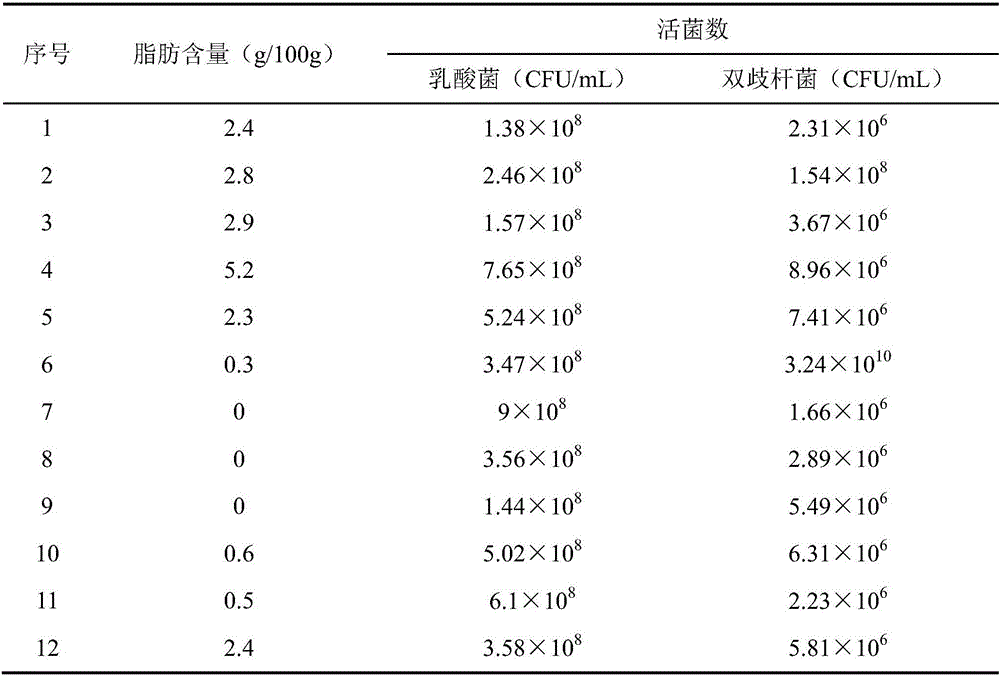

[0068] (1) Weighing of raw materials: Weigh milk, concentrated milk protein, concentrated whey protein, white sugar, glucose, glycerin, anhydrous butter, compound thickener and demineralized water according to the amounts of 1-3 in Table 1;

[0069] (2) Protein hydration: heat up 20% of the mass of softened water in step (1) to 50°C, add concentrated milk protein and concentrated whey protein, and stir for 25 minutes to obtain a mixed solution 1;

[0070] (3) Ingredients: Warm up 20% of the mass of the milk in step (1) to 55°C, add white granulated sugar, glucose, glycerin, anhydrous butter, and a compound thickener (the compound thickener is Shijiazhuang City Brother Yi The model produced by Lan Food Ingredients Co., Ltd. is the product of XD6040-3); Stir for 10min to obtain mixed solution 2;

[0071] (4) Mixing materials to constant volume: mix the mixed sol...

Embodiment 2

[0079] The low-fat probiotic frozen yoghurt of the present embodiment is prepared according to the following steps:

[0080] (1) Weighing of raw materials: Weigh whole milk powder, concentrated milk protein, concentrated whey protein, white sugar, glucose, glycerin, anhydrous butter, compound thickener and softened water;

[0081] (2) Milk powder and protein hydration: warm up 30% of the softened water mass in step (1) to 60°C, add whole milk powder, concentrated milk protein and concentrated whey protein, and stir for 40 minutes to obtain a mixed solution 1;

[0082] (3) Chemical material: 30% of the mass in the mixed liquid 1 described in step (2) is warmed up to 60°C, and white granulated sugar, glucose, glycerin, anhydrous cream, compound thickener (the compound thickener is Shijiazhuang City Brother Yilan Food Ingredients Co., Ltd. (model XD6040-3); stir for 10-20 minutes to obtain the mixed solution 2;

[0083] (4) Mix the materials to constant volume: cool the mixed s...

Embodiment 3

[0091] The low-fat probiotic frozen yoghurt of the present embodiment is prepared according to the following steps:

[0092] (1) Weighing raw materials: Weigh skimmed milk powder, concentrated milk protein, concentrated whey protein, white sugar, glucose, glycerin, anhydrous butter, compound thickener and softener according to the amounts 7-9 in Table 1. water;

[0093] (2) Milk powder and protein hydration: heat 25% of the softened water mass in step (1) to 55°C, add skim milk powder, concentrated milk protein and concentrated whey protein, and stir for 34 minutes to obtain a mixed solution 1;

[0094] (3) Chemical material: 25% of the mass in the mixed solution 1 described in step (2) is warmed up to 58°C, and white granulated sugar, glucose, glycerin, anhydrous cream, compound thickener are added (the compound thickener is The model produced by Shijiazhuang Brother Yilan Food Ingredients Co., Ltd. is the product of XD6040-3); Stir for 15min to obtain the mixed solution 2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com