Processing method of instant refrigerated cooked red swamp crawfish

A technology of freshwater crayfish and processing methods, applied in the field of aquatic product processing, to achieve the effects of expanding sales radius, improving market competitiveness, and eating convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

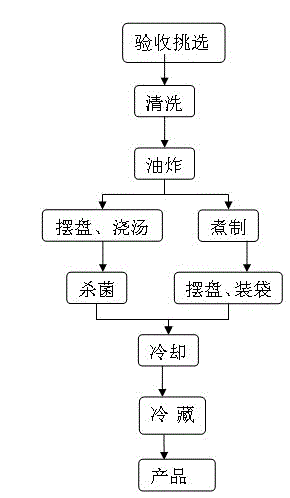

Method used

Image

Examples

Embodiment 1

[0019] Fresh and live freshwater crayfish are used as raw materials, and the weight of shrimp is 50-60g / piece. After acceptance and selection, soak in an aqueous solution containing 0.7% salt and 0.1% citric acid for 40 minutes, and bubble to make the shrimp body spit out the gills and intestines. Then wash the dirt in the glands three times with running water and bubbling. The first step is to soak the lobster in water for 60 minutes. The mass ratio of shrimp to water is 1:8. The second is to wash the mud on the surface of the lobster with compressed air. Some shrimps that are not easy to clean should be scrubbed with a brush. The third is to soak the washed shrimps in ozone water for 10 minutes, and the concentration is 0.4mg / L; then spray and drain with clean water. Using a continuous fryer, fry the drained shrimp in salad oil at a temperature of 210°C for 5 seconds; divide the fried shrimp into two rows in a single layer, with the shrimp claws facing each other Arrange the...

Embodiment 2

[0021] Use fresh freshwater crayfish as raw material, the weight of the shrimp is 40-50g / piece, after acceptance and selection, put it into the aqueous solution containing 0.55% of salt and 0.2% of citric acid for 30 minutes, bubbling, so that the shrimp body spits out the gills and intestines The dirt in the gland is then cleaned in three steps, using running water and bubbling. The first step is to soak the lobster in water for 45 minutes, and the mass ratio of shrimp to water is 1:8. Some shrimps that are not easy to clean should be scrubbed with a brush. The third is to soak the washed shrimps in ozone water for 7 minutes, and the concentration is 0.6mg / L; Dried shrimps are fried in salad oil at a temperature of 195°C for 10 seconds; the fried shrimps are divided into two rows in a single layer, and the shrimp claws are opposite to each other, and the shrimp claws are placed on a plate. Each plate weighs 1 kg. Flatten the shrimp claws on the surface as much as possible to ...

Embodiment 3

[0023] Use fresh freshwater crayfish as raw material, the weight of the shrimp is 30-40g / piece, after acceptance and selection, put it into the aqueous solution containing 0.4% of salt and 0.3% of citric acid for 20 minutes, bubbling, so that the shrimp body spits out the gills and intestines The dirt in the gland is then cleaned in three steps, using running water and bubbling. The first step is to soak the lobster in water for 30 minutes. The mass ratio of shrimp to water is 1:8. The second step is to wash the mud on the surface of the lobster with compressed air. Some shrimps that are not easy to clean should be scrubbed with a brush. The third is to soak the washed shrimps in ozone water for 3 minutes, and the concentration is 0.8mg / L; Dried shrimps are fried in salad oil at a temperature of 180°C for 15 seconds; the fried shrimps are divided into two rows in a single layer, and the shrimp claws are placed opposite to each other on a plate. Each plate weighs 1 kg. Flatten ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com