Compounded stabilizer, normal temperature yoghurt containing compounded stabilizer, and preparation method of yogurt

A compound stabilizer, normal temperature technology, applied in milk preparations, dairy products, applications, etc., can solve problems such as product instability and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

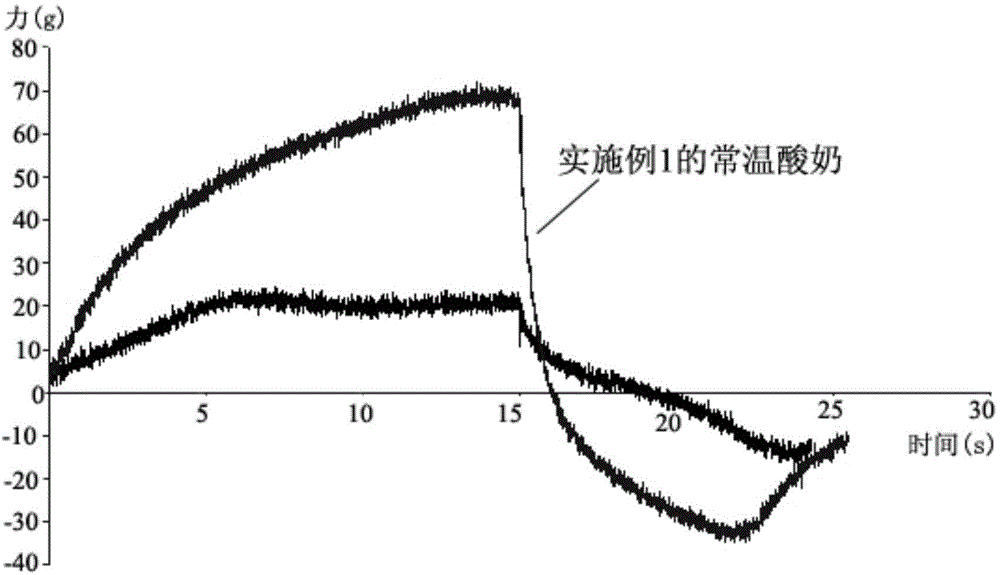

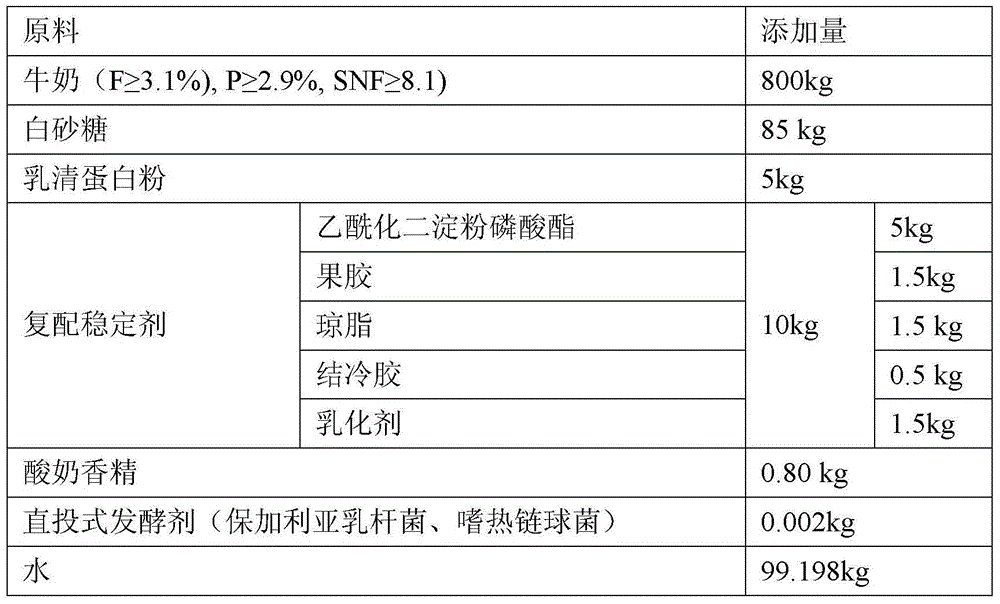

Embodiment 1

[0058] The present embodiment provides a kind of yoghurt at normal temperature, and its raw material composition is as shown in table 1 (in per ton of final product):

[0059] Table 1

[0060]

[0061] The preparation method of this room temperature yoghurt comprises the following steps:

[0062] 1) Pre-sterilize antibiotic-free milk with a fat content of not less than 3.1% and a protein content of not less than 2.9% (anti-antibiotic-free milk is pre-sterilized by a process that combines centrifugal sterilization, homogenization, and high-temperature instantaneous sterilization; centrifugal sterilization The bacteria temperature is kept at 55-65°C, the centrifuge speed is 4200-6300 rpm; the homogenization pressure is 100bar / 20bar; the UHT sterilization is 121°C or 135°C / 4s), and then stored in the cleaned and sterilized stored milk In the tank, the storage temperature is 4-6°C;

[0063] 2) Heat the milk in step 1) to 55°C-60°C through a plate heat exchanger, add whey prot...

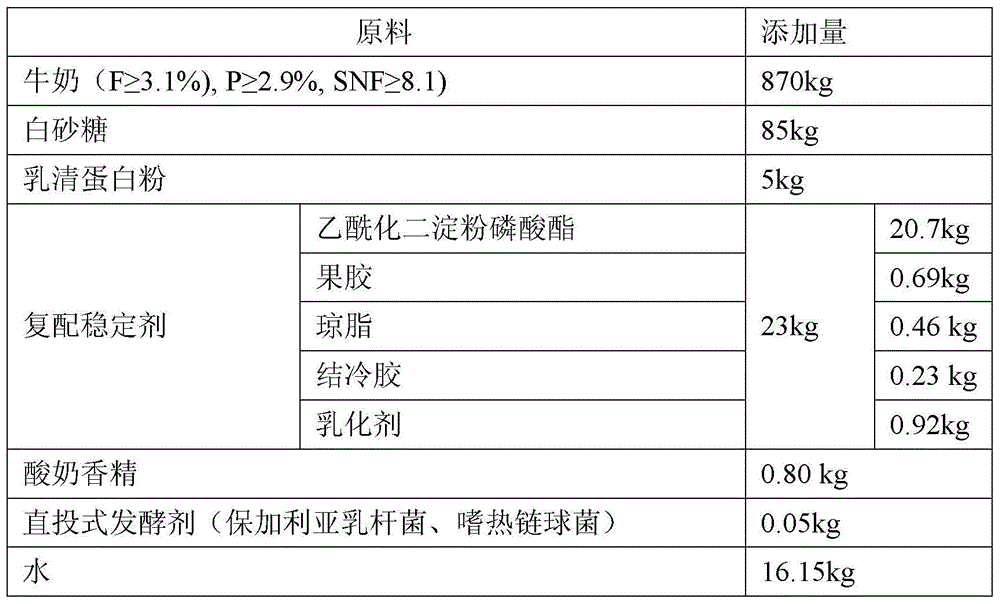

Embodiment 2

[0072] The present embodiment provides a kind of yoghurt at normal temperature, and its raw material composition is as shown in table 2 (in per ton of final product):

[0073] Table 2

[0074]

[0075] The preparation method of this room temperature yoghurt comprises the following steps:

[0076] 1) Pre-sterilize antibiotic-free milk with a fat content of not less than 3.1% and a protein content of not less than 2.9% (anti-antibiotic-free milk is pre-sterilized by a process that combines centrifugal sterilization, homogenization, and high-temperature instantaneous sterilization; centrifugal sterilization The bacteria temperature is kept at 55-65°C, the centrifuge speed is 4200-6300 rpm; the homogenization pressure is 100bar / 20bar; the UHT sterilization is 121°C or 135°C / 4s), and then stored in the cleaned and sterilized stored milk In the tank, the storage temperature is 4-6°C;

[0077] 2) Heat the milk in step 1) to 55°C-60°C through a plate heat exchanger, add whey prot...

Embodiment 3

[0086] The present embodiment provides a kind of yoghurt at normal temperature, and its raw material composition is as shown in table 3 (in per ton of final product):

[0087] table 3

[0088]

[0089] The preparation method of this room temperature yoghurt comprises the following steps:

[0090] 1) Pre-sterilize antibiotic-free milk with a fat content of not less than 3.1% and a protein content of not less than 2.9% (anti-antibiotic-free milk is pre-sterilized by a process that combines centrifugal sterilization, homogenization, and high-temperature instantaneous sterilization; centrifugal sterilization Bacterial temperature is maintained at 55-65°C, centrifuge rotation speed is 4200-6300 rpm; homogenization pressure is 100bar / 20bar; UHT sterilization is 121°C or 135°C / 4s) and should be stored in cleaned and sterilized stored milk In the tank, keep refrigerated before use at a storage temperature of 4-6°C;

[0091] 2) Heat the milk in step 1) to 55°C-60°C through a plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com