Normal-temperature drinking type yoghourt and preparation method thereof

A drinkable and yogurt technology, applied in milk preparations, applications, dairy products, etc., can solve problems such as poor taste of room temperature yogurt, large residual wall hanging, and short shelf life of low-temperature drinking yogurt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

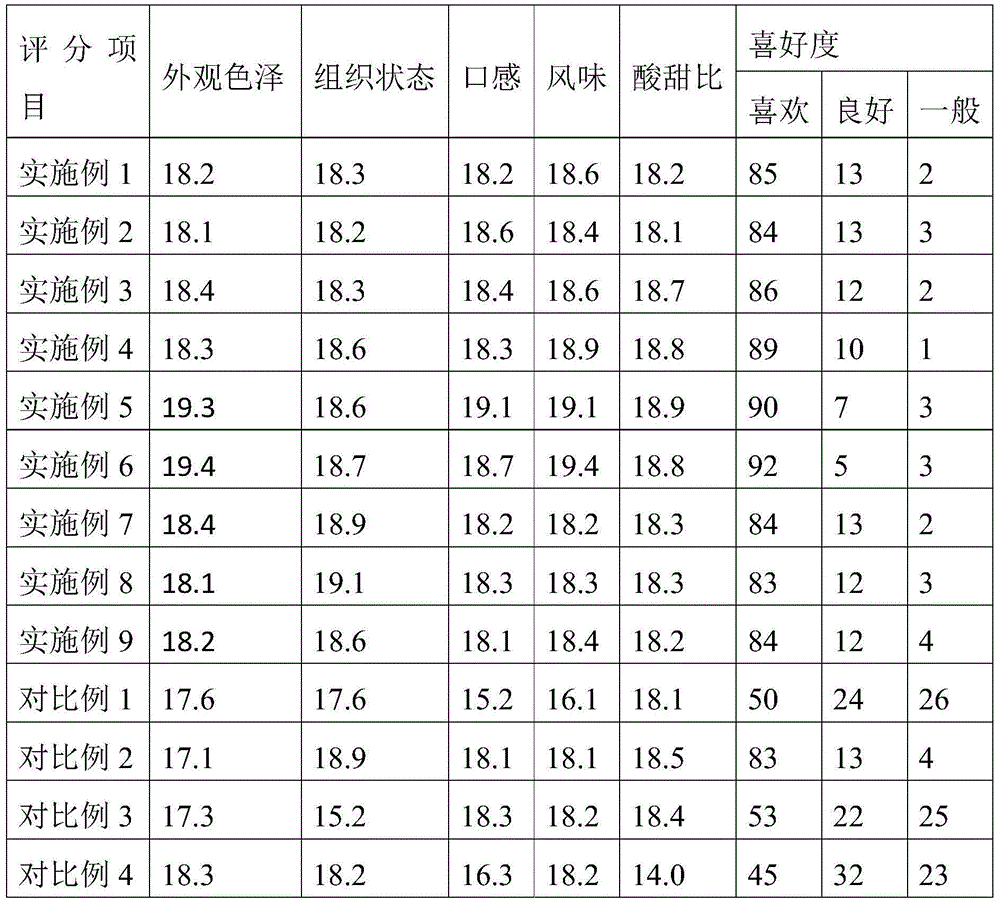

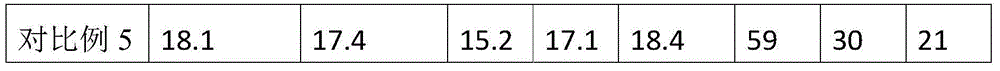

Examples

Embodiment 1

[0029] (1) Mix 95% of whole milk and 5% of whole milk powder evenly, the percentage is the mass percentage of the total mass of the mixture, and the protein content is 3.93%, and the percentage is the percentage of the protein mass in the concentrated raw milk The mass percentage of the total mass, stirring at 45°C for 15 minutes, 15Mpa, 54°C first-level homogenization, 132°C sterilization for 4s, to obtain sterilized concentrated raw milk, the mass of the whole milk and whole milk powder accounted for the total mass of normal temperature drinking yogurt products The mass percentages are 55.67% and 2.93%, respectively.

[0030] (2) Cool the sterilized and concentrated raw milk to 37°C, add Lactobacillus bulgaricus 1×10 6 cfu / mL and Streptococcus thermophilus 1×10 6 cfu / mL, enzymatic hydrolysis and fermentation were carried out simultaneously at 37°C. After 10 hours, the acidity reached 80°T, the fermentation was stopped, the tank was turned over with back pressure, 15Mpa firs...

Embodiment 2

[0034] (1) Mix 97.5% of skimmed milk and 2.5% of skimmed milk powder evenly, the percentage is the mass percentage of the total mass of the mixed solution, and the protein content is 3.85%, and the percentage is the percentage of the total mass of the concentrated raw milk that the protein mass accounts for Mass percentage, 45°C stirring for 15 minutes, 15Mpa 54°C primary homogenization, 132°C sterilization for 4s to obtain sterilized concentrated raw milk, the mass percentages of the skimmed milk and skimmed milk powder in the total mass of normal temperature drinking yogurt products are respectively 58.51% and 1.49%.

[0035] (2) Cool the sterilized and concentrated raw milk to 37°C, add Lactobacillus bulgaricus 1×10 6 cfu / mL and Streptococcus thermophilus 1×10 6 cfu / mL, enzymatic hydrolysis and fermentation were carried out simultaneously at 37°C. After 9 hours, the acidity reached 82°T, the fermentation was stopped, the tank was turned over with back pressure, 15Mpa first...

Embodiment 3

[0039] (1) Mix 93% of whole milk and 7% of whole milk powder evenly, the percentage is the mass percentage of the total mass of the mixture, and the protein content is 4.34%, and the percentage is the percentage of the protein mass in the concentrated raw milk The mass percentage of the total mass, stirring at 50°C for 20 minutes, first-level homogenization at 57°C at 17Mpa, second-level homogenization at 2Mpa, sterilization at 135°C for 6s, to obtain sterilized concentrated raw milk, the mass of the whole milk and whole milk powder accounted for The mass percentages of the total mass of normal temperature drinking yoghurt products are 55.8% and 4.2% respectively.

[0040] (2) Cool the sterilized and concentrated raw milk to 37°C, add Lactobacillus bulgaricus 6×10 6 cfu / mL and Streptococcus thermophilus 6×10 6 cfu / mL, Lactobacillus casei subspecies 2×10 6 cfu / mL, fermentation was carried out simultaneously at 39°C, after 8 hours the acidity reached 81°T, the fermentation was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com