Preparation method for compound lithium ion battery cathode material and application of petroleum resin in preparation method

A petroleum resin and ion battery technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of poor compatibility of non-polar polymers, not suitable for single use, poor aging resistance, etc., and achieve uniform particle size Controllable, easy to implement, and solve the difficult effects of production design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

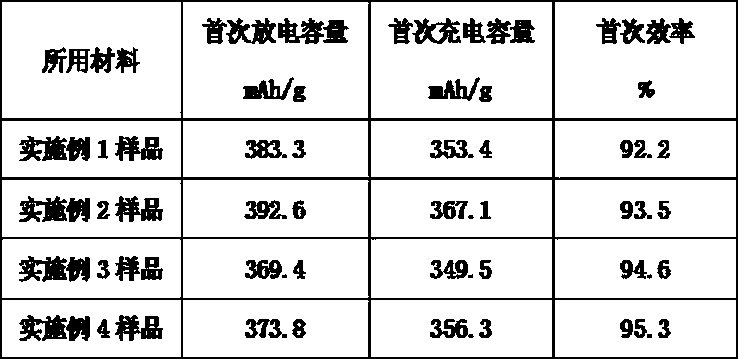

Examples

Embodiment 1

[0037] An application of petroleum resin in the preparation of negative electrode materials for composite lithium-ion batteries. The petroleum resin is used as the coating material of the core material. The petroleum resin is also called hydrocarbon resin. A thermoplastic resin formed by polymerizing olefins or copolymerizing with aldehydes, aromatics, and terpenes. It includes four types: aliphatics, aromatics, cycloaliphatic dienes, and pure monomers. The molecular weight is between Between 300 and 5000; the particle size of the petroleum resin is less than 10 μm.

[0038] In the present invention, when the hard carbon material is used as the primary coating material of the core material, the petroleum resin is used as the secondary coating modification material.

[0039] The particle size of the petroleum resin of the present invention is preferably below 5 μm, and the petroleum resin is preferably C5 petroleum resin or C9 petroleum resin; the C5 petroleum resin is light ye...

Embodiment 2

[0063] In this embodiment, C9 petroleum resin is selected as the secondary coating modification material.

[0064] In step (1), the heteroatom additive described in this embodiment is diboron trioxide, the thermosetting resin is epoxy resin, and the carbon element content is 60%, and the organic solvent is ethanol, preferably absolute ethanol; Take 20g of diboron trioxide, 70g of epoxy resin, and 150g of absolute ethanol, and turn on the stirring device of the reactor. precursor solution.

[0065] In step (2), in this embodiment, 120 g of microcrystalline graphite with an average particle size of 10 μm was weighed, slowly added into the stirring reactor, and kept stirring for 180 minutes to obtain a precursor fluid slurry.

[0066] In step (3), keep the stirring device of the reactor open, and at the same time evacuate the reactor to keep the relative vacuum pressure of the reactor at -0.09MPa; Stir for 240 minutes, then continue to heat up to 200°C, keep stirring at this te...

Embodiment 3

[0072] In this embodiment, C9 petroleum resin is selected as the secondary coating modification material.

[0073] In step (1), the heteroatom additive described in this embodiment is boron phosphate, the thermosetting resin is furan resin, and the organic solvent is isopropanol, preferably anhydrous isopropanol; respectively weigh 20g boron phosphate, 70g Furan resin, 150g of anhydrous isopropanol, turn on the stirring device of the reaction kettle, put the weighed raw materials into the reaction kettle at room temperature, and then continue stirring for 90 minutes to obtain a precursor solution that is uniformly mixed and uniform in color.

[0074] In step (2), in this embodiment, 300 g of needle coke graphite with an average particle size of 22 μm was weighed, slowly added into the stirring reactor, and kept stirring for 150 min to obtain a precursor fluid slurry.

[0075] In step (3), keep the stirring device of the reactor open, and at the same time evacuate the reactor t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com