Preparation method and application of acrylate pressure-sensitive adhesive

A pressure-sensitive adhesive and acrylate technology, applied in adhesives, ester copolymer adhesives, adhesive types, etc., can solve the problems of residual adhesive residue, poor light transmittance, etc., and achieve good adhesion and excellent rework performance , the effect of high bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

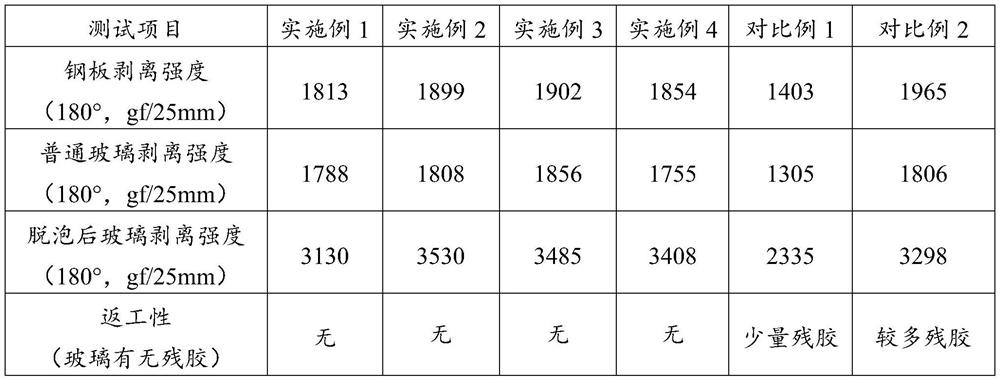

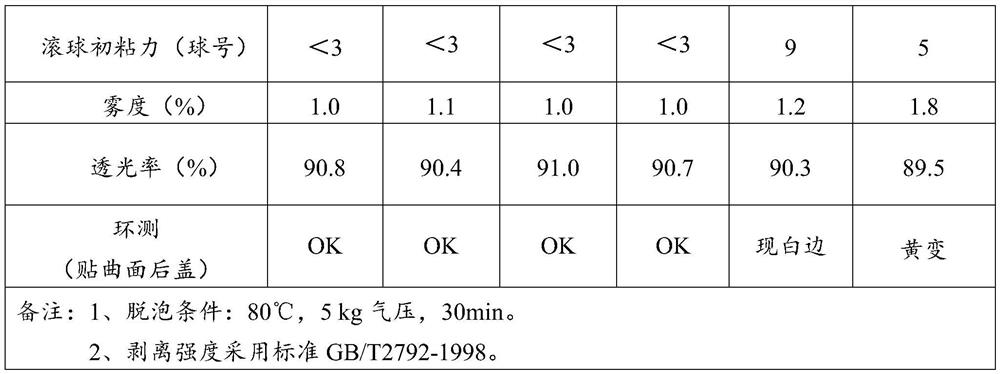

Examples

Embodiment 1

[0032] (1) Preparation of acrylate copolymer:

[0033] Weigh 30 parts of butyl acrylate, 10 parts of isobornyl acrylate, 50 parts of methyl acrylate, 3 parts of itaconic acid, 7 parts of hydroxyethyl acrylamide, heat up to 65°C under nitrogen atmosphere and stir evenly for 30 minutes, then Add 0.05 parts of azobisisobutyronitrile to react smoothly for 90 minutes. Raise the temperature to 80° C., add 0.05 parts of azobisisobutyronitrile and react for 240 minutes to prepare an acrylate copolymer. The resulting acrylate copolymer has a viscosity of 5000 cps (25°C), a solid content of 30%, a molecular weight of about 500,000, and a glass transition temperature Tg of -20°C.

[0034] (2) Preparation of acrylate pressure-sensitive adhesive:

[0035] Add 0.4 parts of curing agent TDI toluene diisocyanate and 20 parts of solvent ethyl acetate to the above-mentioned acrylate copolymer; mix and stir all the components evenly, let stand for defoaming, and obtain the acrylate pressure-se...

Embodiment 2

[0037] (1) Preparation of acrylate copolymer:

[0038] Weigh 60 parts of 2-ethylhexyl acrylate, 30 parts of isobornyl acrylate, 2 parts of acrylic acid, 3 parts of itaconic acid, and 5 parts of hydroxyethylacrylamide. Put the above raw materials into a 1000ml reaction kettle, raise the temperature to 65° C. and stir evenly for 30 minutes under nitrogen atmosphere, and then add 0.3 parts of azobisisoheptanonitrile to react stably for 90 minutes. Heat up to 80° C., add 0.3 parts of azobisisoheptanonitrile and react for 240 minutes to prepare an acrylate copolymer. The obtained acrylate copolymer has a viscosity of 2500 cps (25°C), a solid content of 29%, a molecular weight of about 300,000, and a glass transition temperature Tg of -19.5°C.

[0039] (2) Preparation of acrylate pressure-sensitive adhesive:

[0040] Add 0.6 parts of curing agent 1,3-bis(N,N-diglycidylaminomethyl)cyclohexane to the above-mentioned acrylate copolymer, and 40 parts of ethyl acetate as a solvent; mix...

Embodiment 3

[0042] (1) Preparation of acrylate copolymer:

[0043] Weigh 40 parts of butyl acrylate, 30 parts of isobornyl acrylate, 15 parts of itaconic acid, and 3 parts of hydroxyethylacrylamide. Put the above raw materials into a 1000ml reaction kettle, raise the temperature to 65°C under nitrogen atmosphere and stir evenly for 30 minutes, then add 0.1 part of azobisisovaleronitrile to react stably for 90 minutes. Raise the temperature to 80° C., add 0.2 parts of azobisisovaleronitrile and react for 240 minutes to prepare an acrylate copolymer. The obtained acrylate copolymer has a viscosity of 4000 cps (25°C), a solid content of 30%, a molecular weight of about 1 million, and a glass transition temperature Tg of -18°C.

[0044] (2) Preparation of acrylate pressure-sensitive adhesive:

[0045] Add 0.5 parts of aluminum acetylacetonate curing agent and 30 parts of ethyl acetate as solvent to the above-mentioned acrylate copolymer; mix and stir all the components evenly, and let stand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com