Double-faced pressure-sensitive adhesive tape for affixing decorative panel

A double-sided adhesive tape and decorative board technology, which is applied in the direction of adhesive type, ester copolymer adhesive, film/sheet adhesive, etc., can solve the problem of height difference in resilience resistance and followability of curved components Insufficient, insufficient adhesiveness and other problems, to achieve the effect of low VOC, excellent VOC suppression, high adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

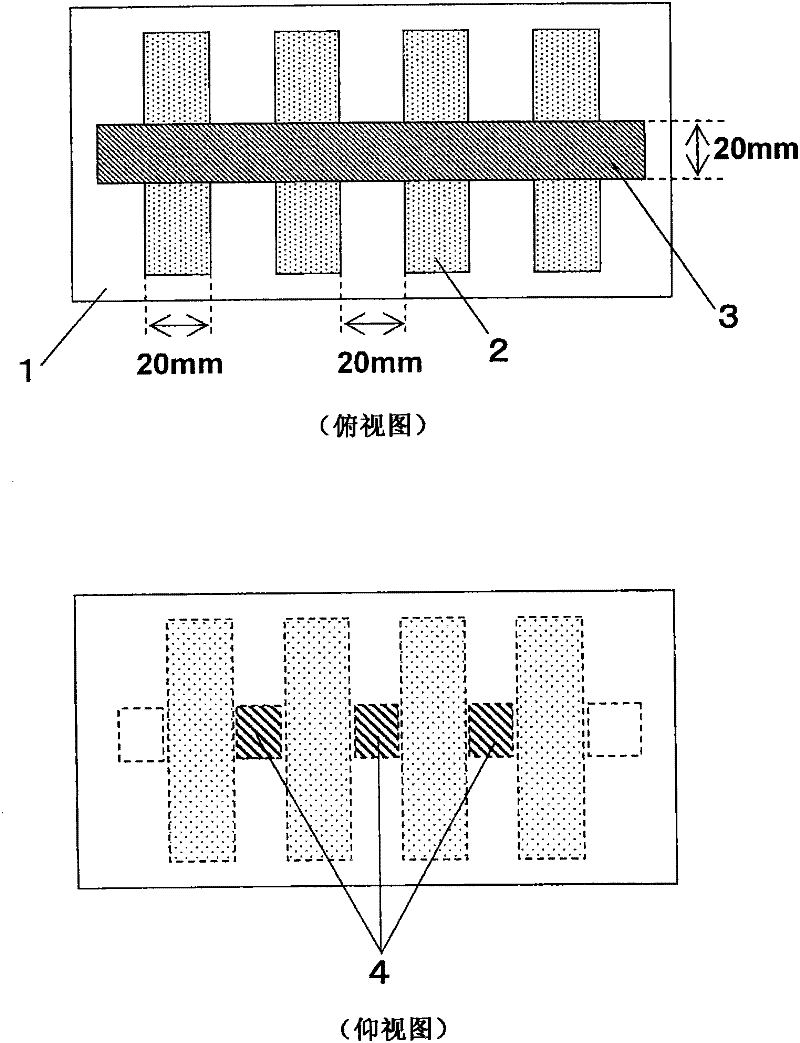

Image

Examples

preparation example Construction

[0067] In the production method of the bubble-containing adhesive, the method of mixing bubbles is not particularly limited, and known bubble mixing methods can be used. For example, as an example of the device, a device having a stator having many fine teeth on a disk having a through hole in the center and a rotor facing the toothed stator and having the same fine teeth on the disk as the stator can be cited. Wait. By introducing a compound mixed with air bubbles between the teeth of the stator and rotor of this device and rotating the rotor at a high speed, while introducing a gas component for forming air bubbles (bubble forming gas) through the through holes, thereby A bubble-containing adhesive in which the bubble-forming gas is finely dispersed and mixed can be obtained.

[0068] In addition, in order to suppress or prevent coalescence of air bubbles, it is preferable to continuously perform the steps from mixing of air bubbles to formation of an adhesive layer as a se...

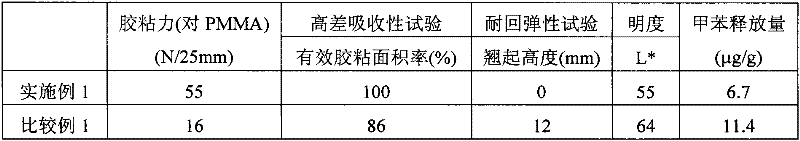

Embodiment 1

[0109] Into a monomer mixture obtained by mixing 90 parts by weight of 2-ethylhexyl acrylate and 10 parts by weight of acrylic acid as a monomer component, was blended a photoresist with the trade name "Irgacyua 651" (manufactured by Chiba Specialty Chemical Co., Ltd.) After 0.05 parts by weight of a polymerization initiator and 0.05 parts by weight of a photopolymerization initiator with a trade name of "Irgakiyua 184" (manufactured by Chiba Specialty Chemicals Co., Ltd.), ultraviolet light was irradiated until the viscosity (BH viscometer, No. 5 rotor, 10 rpm, Measurement temperature: 30° C.) reaches about 15 Pa·s, and a partially polymerized composition (slurry) is prepared. To 100 parts by weight of the slurry, 0.04 parts by weight of a photopolymerization initiator, 0.1 parts by weight of 1,6-hexanediol diacrylate, 0.7 parts by weight of a fluorine-containing surfactant with a trade name of "Megafact F-477" (manufactured by DIC Corporation) and 0.02 parts by weight of car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com