Special primer paint for medium and high grade automobile aluminum hubs and preparation method of primer paint

A medium-to-high-end, automotive technology, used in powder coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of poor leveling, rough coating surface, and high price of aluminum wheel base powder coatings, and achieve excellent adhesion. and physical and mechanical properties, good salt spray resistance, short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

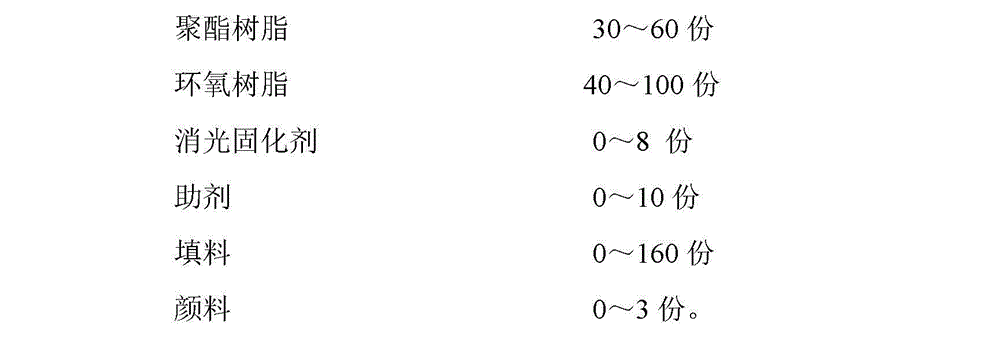

Method used

Image

Examples

Embodiment 1

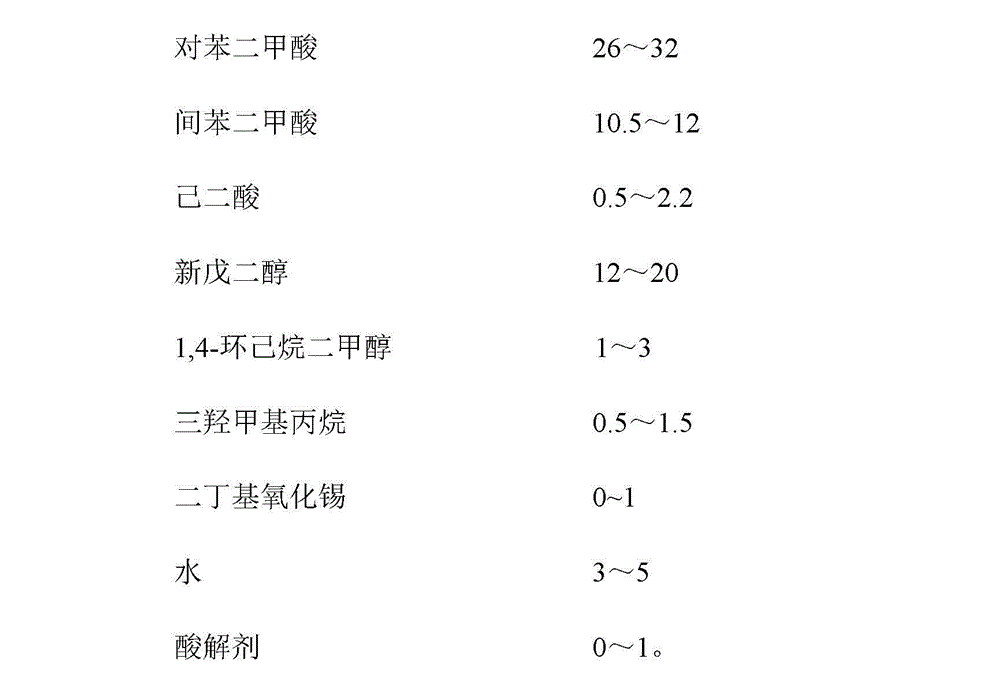

[0055] Present embodiment adopts the saturated carboxyl polyester resin that resin adopts acid value 30~35mgKOH / g, and its preparation method is as follows:

[0056] 1) In the reactor, add 12Kg of neopentyl glycol, 0.5kg of trimethylolpropane, 1kg of 1,4-cyclohexanedimethanol and 3kg of water, and heat to melt;

[0057] 2) Add 26kg of terephthalic acid, 10.5kg of isophthalic acid, 0.5kg of adipic acid and 0.1kg of dibutyltin oxide in sequence, and continue to heat up to 130°C with nitrogen;

[0058] 3) The temperature is heated from 130°C to 250°C until the acid value reaches 13mgKOH / g, and the first time vacuumizes for polycondensation reaction. When the acid value reaches 4mgKOH / g, the softening point is 100°C and the melt viscosity at 200°C is 3000mpa.s, Add 0.05kg of acidolysis agent isophthalic acid to carry out acidolysis reaction. When the acid value reaches 40mgKOH / g, vacuumize for the second time to carry out acidolysis reaction until the acid value of the reaction pr...

Embodiment 2

[0076] Present embodiment adopts the saturated carboxyl polyester resin that resin adopts acid value 30~60mgKOH / g, and its preparation method is as follows:

[0077] 1) In the reaction kettle, add 14kg of neopentyl glycol, 1.0kg of trimethylolpropane, 2.0kg of 1,4-cyclohexanedimethanol and 4.0 of water, and heat to melt;

[0078] 2) Add 30kg of terephthalic acid, 11kg of isophthalic acid, 1.0kg of adipic acid and 0.5kg of dibutyltin oxide in sequence, and continue to heat up to 130°C with nitrogen;

[0079] 3) The temperature is heated from 130°C to 250°C until the acid value reaches 15mgKOH / g, and the first time vacuumizes for polycondensation reaction. When the acid value reaches 5mgKOH / g, the softening point is 103°C and the melt viscosity at 200°C is 3200mpa.s, Add 0.5kg of acidolysis agent isophthalic acid for acidolysis reaction. When the acid value reaches 42mgKOH / g, the second vacuum acidolysis reaction is carried out until the acid value of the reaction product is 30~...

Embodiment 3

[0090] The present embodiment adopts the saturated carboxyl polyester resin with an acid value of 30-60 mgKOH / g as the resin, and its preparation method is the same as that shown in Example 2. The preparation of epoxy resin is as shown in embodiment 1.

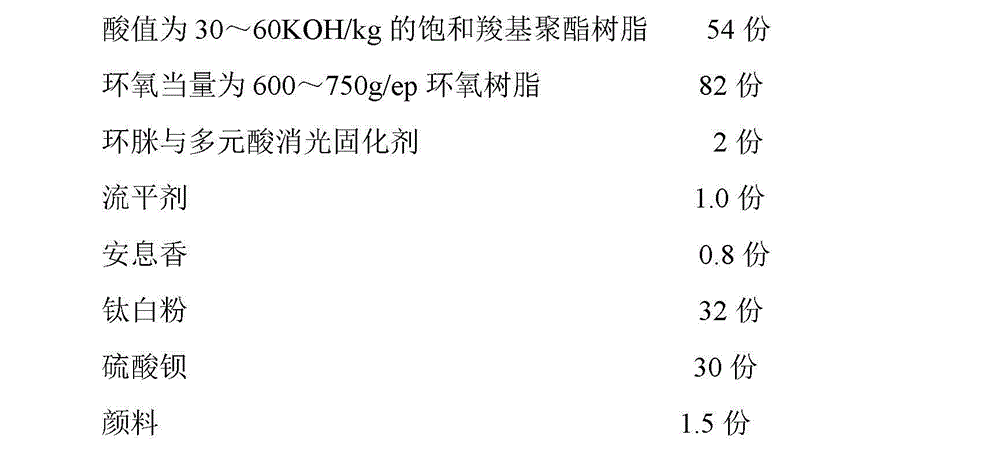

[0091]

[0092]

[0093] Preparation:

[0094] (a) Weigh the saturated carboxyl polyester resin with an acid value of 30-60KOH / kg, epoxy resin with an epoxy equivalent of 600-750g / ep, cyclic amidine and multi-acid matting curing agent, titanium dioxide, barium sulfate, Acrylic leveling agent PLP-100, benzoin, and pigments are placed in the mixing tank, fully mixed and crushed for 1 to 10 minutes;

[0095] (b) The crushed material enters the twin-screw extruder for extrusion; the heating temperature of the extruder is controlled at 80-120°C;

[0096] (c) The extruded material is compressed into tablets, cooled, and pulverized into a powder with a particle size (equivalent particle size D50) of 30-45 um, then sieved and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com