Method for preparing sample band for testing carbon fiber tow

A technology of carbon fiber and fiber tow, which is applied in the field of testing and research, and can solve problems such as difficulty in adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

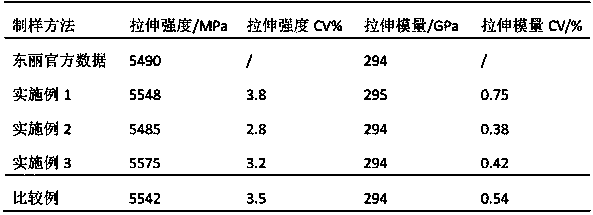

Examples

Embodiment 1

[0018] (1) Configuration of water-based epoxy resin impregnation solution: add deionized water to water-based epoxy resin F0404 (solid content is 45%, epoxy equivalent value is 0.18mol / 100g, viscosity is 300cps), stir evenly, and configure Epoxy resin mass percent is the aqueous solution of 30%; Add water-based epoxy resin curing agent F0405 (solid content 50%, amine hydrogen equivalent value is 200, viscosity is 1500cps), the combination of water-based epoxy resin and water-based epoxy resin curing agent The mass ratio is 1:1; stir evenly to obtain a water-based epoxy resin impregnating solution;

[0019] (2) Fiber bundle pre-treatment: Wrap the T800 grade 12K carbon fiber tow produced by Toray Corporation of Japan on the fixed frame, apply a tension of 5N during the winding process, and soak for 3 minutes in a 1% epoxy phosphate aqueous solution with a mass ratio;

[0020] (3) Impregnation of fiber bundles: placing the fiber bundles treated in step (2) together with the fram...

Embodiment 2

[0024] (1) Configuration of water-based epoxy resin impregnation solution: add deionized water to water-based epoxy resin F0404 (solid content is 45%, epoxy equivalent value is 0.20mol / 100g, viscosity is 600cps), stir evenly, and configure Epoxy resin mass percentage is the aqueous solution of 25%; Add water-based epoxy resin curing agent F0405 (solid content 50%, amine hydrogen equivalent value is 250, and viscosity is 1500cps), the combination of water-based epoxy resin and water-based epoxy resin curing agent The mass ratio is 0.75:1, and the mixture is evenly stirred to obtain a water-based epoxy resin impregnation solution;

[0025] (2) Pre-treatment of fiber bundles: Wrap T800 grade 12K carbon fiber tows produced by Japan Toray Co., Ltd. on a fixed frame, apply a tension of 3N during the winding process, and soak for 1 minute in an aqueous solution of 2% phosphate methacrylate by mass ;

[0026] (3) Impregnation of fiber bundles: placing the fiber bundles treated in ste...

Embodiment 3

[0030] (1) (2) with embodiment 1;

[0031] (3) Impregnation of fiber bundles: placing the fiber bundles treated in step (2) together with the frame in the water-based epoxy resin impregnating solution of step (1) for 10 minutes;

[0032] (4) Curing: Take the carbon fiber tow and the frame out of the dipping solution and let it stand for 2 minutes, then put it in an oven at 130°C for drying and curing for 2 hours;

[0033] (5) Removal of fiber tows: remove the carbon fiber tows from the fixing frame with tools such as scissors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com