Expansion type fireproof silicone rubber strip

A silicone rubber, intumescent technology, applied in the field of intumescent fireproof silicone rubber strips, can solve the problems of high heat release rate, unenvironmental protection, poor heat insulation effect, etc., and achieves low heat release rate, less smoke, and fire resistance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of surface treatment agent

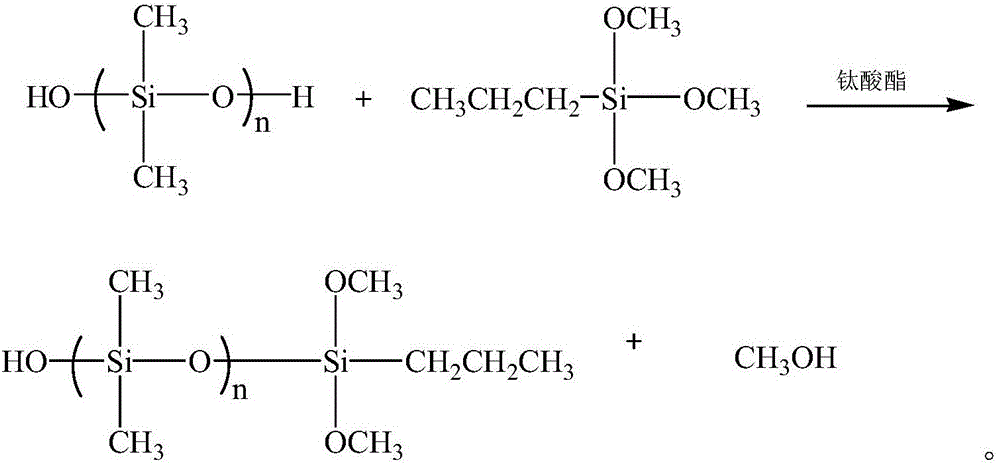

[0030] Use low viscosity hydroxy silicone oil (HO(CH 3 SiCH 3 ) 3 H, commercially available) and propyltrimethoxysilane (CH 3 CH 2 CSi(OCH 3 ) 3 , commercially available), in parts by mass of 1:1, under the action of a titanate catalyst (preferably butyl titanate, analytically pure, Shanghai Meixing Chemical Co., Ltd.), after reacting at 100°C for 4 hours, and in a vacuum The low molecular weight was removed at -0.06MPa for 2 hours, and the obtained product was used as a surface treatment agent.

[0031] (2) Surface treatment of expanded graphite

[0032] Use absolute ethanol (analytical grade) and water (distilled water) in 2:8 parts by weight, and stir evenly to obtain an ethanol solution. The surface treatment agent and the ethanol solution were prepared in parts by weight of 1:9, while stirring, acetic acid was added dropwise to adjust the pH value to 3, and stirred at room temperature for 30 minutes to obtain a s...

Embodiment 2

[0039] (1) Preparation of surface treatment agent

[0040] Use low viscosity hydroxy silicone oil (HO(CH 3 SiCH 3 ) 4 H, commercially available) and propyltrimethoxysilane (CH 3 CH 2 CSi(OCH 3 ) 3 , commercially available), in parts by mass of 1:1, under the action of a titanate catalyst (commercially available), react at 100°C for 3 hours, and delower molecular weight for 2 hours under a vacuum of -0.08MPa to obtain The product is used as a surface treatment agent.

[0041] (2) Surface treatment of expanded graphite

[0042] Use absolute ethanol (analytical grade) and water (distilled water) in 2:8 parts by weight, and stir evenly to obtain an ethanol solution. The surface treatment agent and the ethanol solution were prepared in parts by weight of 1:9, while stirring, acetic acid was added dropwise to adjust the pH value to 4, and stirred at room temperature for 30 minutes to obtain a surface treatment agent solution, the content of which was 10%. Add the expanded gra...

Embodiment 3

[0049] (1) Preparation of surface treatment agent

[0050] Use low viscosity hydroxy silicone oil (HO(CH 3 SiCH 3 ) 5 H, commercially available) and propyltrimethoxysilane (CH 3 CH 2 CSi(OCH 3 ) 3 , commercially available), according to the mass fraction of 1:1, under the action of a titanate catalyst (commercially available), react at 100°C for 4 hours, and delower the molecule under vacuum -0.08MPa for 2 hours to obtain The product is used as a surface treatment agent.

[0051] (2) Surface treatment of expanded graphite

[0052] Use absolute ethanol (analytical grade) and water (distilled water) in 2:8 parts by weight, and stir evenly to obtain an ethanol solution. The surface treatment agent and the ethanol solution were prepared in parts by weight of 1:9, while stirring, acetic acid was added dropwise to adjust the pH value to 5, and stirred at room temperature for 30 minutes to obtain a surface treatment agent solution, the content of which was 10%. Add the expan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com