Vitrified tile paving structure and paving method thereof

A vitrified brick and paving technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of insufficient strength of the base surface, large thickness of adhesive, hollowing of vitrified bricks, etc., and achieve less consumption per unit area , Sealing and curing speed is fast, and the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] 1) Preparation of gum:

[0057] a. Weigh each component according to the following percentage by weight: styrene-butadiene emulsion 42%, styrene-acrylic emulsion 34%, water 20%, reinforcing agent 2.0%, anti-fungal agent 0.5%, defoamer 1.0% and water repellent 0.5% %, and then mix and stir the weighed components to make liquid material components.

[0058] b. each component is weighed by the following percentage by weight: Portland cement 48%, river sand 48%, cellulose ether 0.5%, water reducer 0.5%, organosilicon powder 1.5% and nano silicon oxide 1.5%, then Mix and stir the weighed components to make powder components.

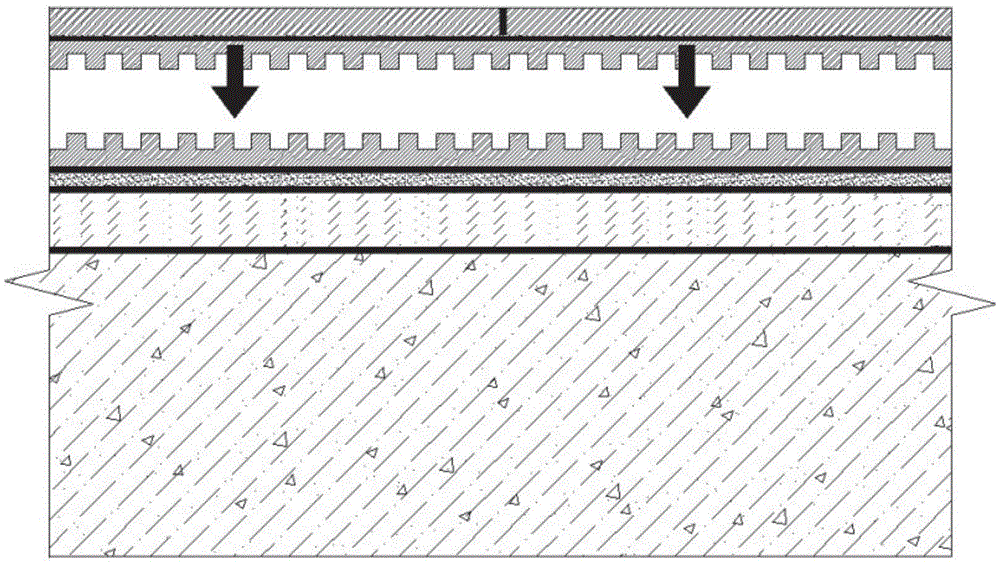

[0059] 2) Treatment of vitrified tiles: clean up the dust, dirt, oil stains, release agent residues, etc. Mix evenly with a weight ratio of 1:2.5 and apply it on the back of the vitrified tile, the thickness is about 0.5mm, and the dosage is about 0.5Kg / m 2 , the surface drying time at room temperature is 1 hour, and the natural curing time is not l...

Embodiment 2

[0067] 1) Preparation of gum:

[0068] a. Weigh each component according to the following weight percentage content: styrene-butadiene emulsion 45%, styrene-acrylic emulsion 31%, water 20%, reinforcing agent 2.5%, anti-fungal agent 0.5%, defoamer 0.5% and water repellent 0.5% %, and then mix and stir the weighed components to make liquid material components.

[0069] b. each component is weighed by the following percentage by weight: Portland cement 50%, river sand 46%, cellulose ether 0.5%, water reducer 0.5%, organosilicon powder 1.5% and nano silicon oxide 1.5%, then Mix and stir the weighed components to make powder components.

[0070] c. Mix and stir the prepared liquid component and powder component in a weight ratio of 1:2 to form a back glue.

[0071] 2) Treatment of vitrified tiles: clean up the dust, dirt, oil stains, release agent residues, etc. On the back of vitrified tiles, the thickness is about 0.3mm, and the dosage is about 0.3Kg / m 2 , the surface drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com