Waterproof buffer glue, and preparation method and application method thereof

A glue and polymer technology, applied in adhesives, polyurea/polyurethane adhesives, film/sheet adhesives, etc., can solve the problems of high prices and achieve low cost, cost reduction, and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

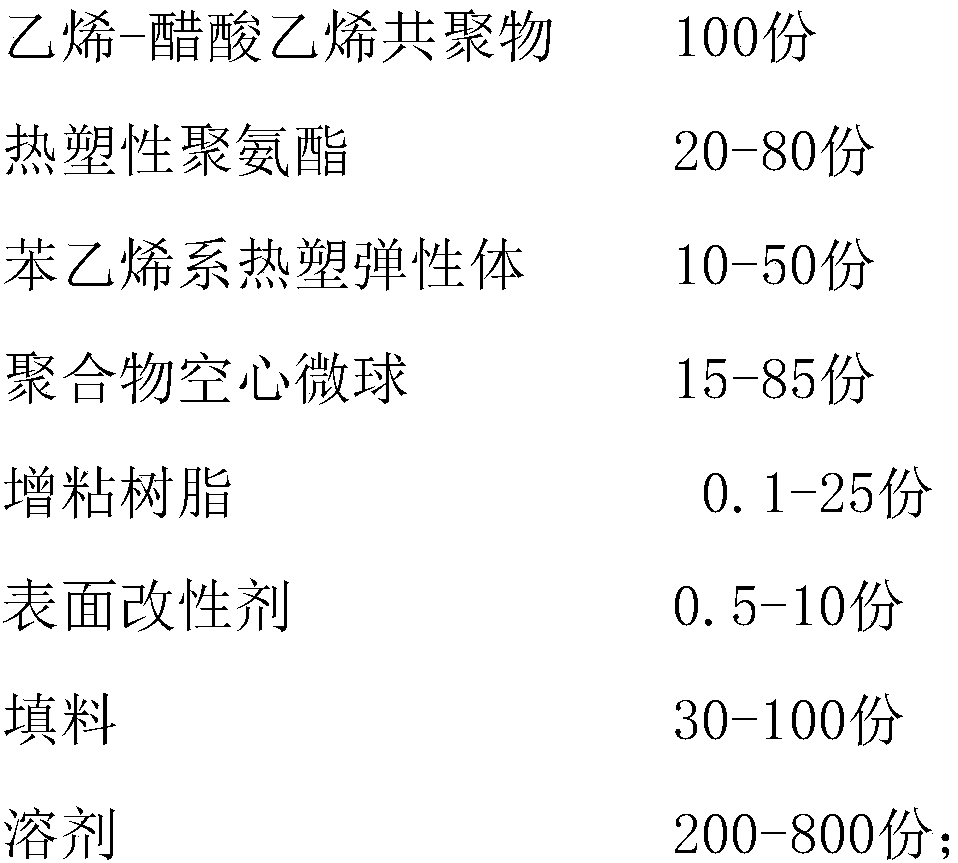

[0039] A waterproof buffer glue, comprising the following raw materials in parts by weight:

[0040]

[0041]

[0042] Wherein, the polymer hollow microspheres are foamed and expanded microspheres with a core-shell structure.

[0043] The styrene-based thermoplastic elastomer is a styrene-butadiene-styrene block copolymer.

[0044] The tackifying resin is rosin resin.

[0045] The surface modifier is a silane coupling agent; the silane coupling agent is γ-aminopropyltriethoxysilane.

[0046] The filler is compounded by glass fiber powder and inorganic cobalt blue pigment according to the mass ratio of 2:1.

[0047] The solvent is formed by compounding toluene and butanone according to the mass ratio of 2:1.5.

[0048] The preparation method of described waterproof buffer glue, comprises the following steps:

[0049] (1) Add polymer hollow microspheres, inorganic fillers, and surface modifiers to a part of the solvent in sequence, stir and disperse evenly to obtain a ...

Embodiment 2

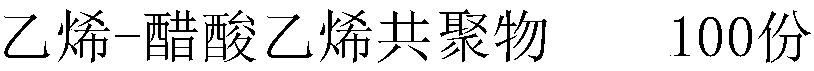

[0056] A waterproof buffer glue, comprising the following raw materials in parts by weight:

[0057]

[0058] Wherein, the polymer hollow microspheres are foamed and expanded microspheres with a core-shell structure.

[0059] The styrene-based thermoplastic elastomer is a styrene-ethylene-butylene-styrene block copolymer.

[0060] The tackifying resin is terpene resin.

[0061] The surface modifier is a silane coupling agent; the silane coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane.

[0062] The filler is an inorganic filler, and the inorganic filler is composed of quartz sand and graphite according to a mass ratio of 3:2.

[0063] The solvent is compounded by xylene and butanone according to the mass ratio of 25:18.

[0064] The preparation method of described waterproof buffer glue, comprises the following steps:

[0065] (1) Add polymer hollow microspheres, inorganic fillers, and surface modifiers to a part of the solvent in sequence, stir and disperse ev...

Embodiment 3

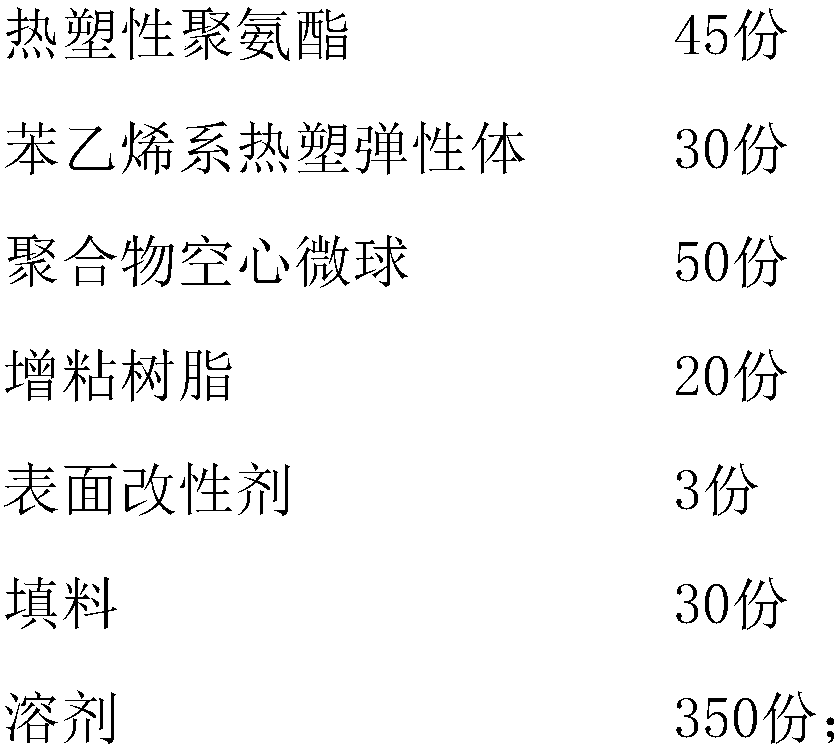

[0072] A waterproof buffer glue, comprising the following raw materials in parts by weight:

[0073]

[0074]

[0075] Wherein, the polymer hollow microspheres are foamed and expanded microspheres with a core-shell structure.

[0076] The styrene-based thermoplastic elastomer is a styrene-ethylene-butylene-styrene block copolymer.

[0077] The tackifying resin is C5 petroleum resin.

[0078] The surface modifier is a silane coupling agent; the silane coupling agent is γ-methacryloxypropyltrimethoxysilane.

[0079] The filler is an inorganic filler, and the inorganic filler is compounded by fumed silica and inorganic olive green pigment according to a mass ratio of 2:1.

[0080] The solvent is prepared by compounding ethyl ester and toluene according to the mass ratio of 12:35.

[0081] The preparation method of described waterproof buffer glue, comprises the following steps:

[0082] (1) Add polymer hollow microspheres, inorganic fillers, and surface modifiers to a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com