Nickel-cobalt-manganese core-shell structure precursor, preparation method thereof and positive electrode material

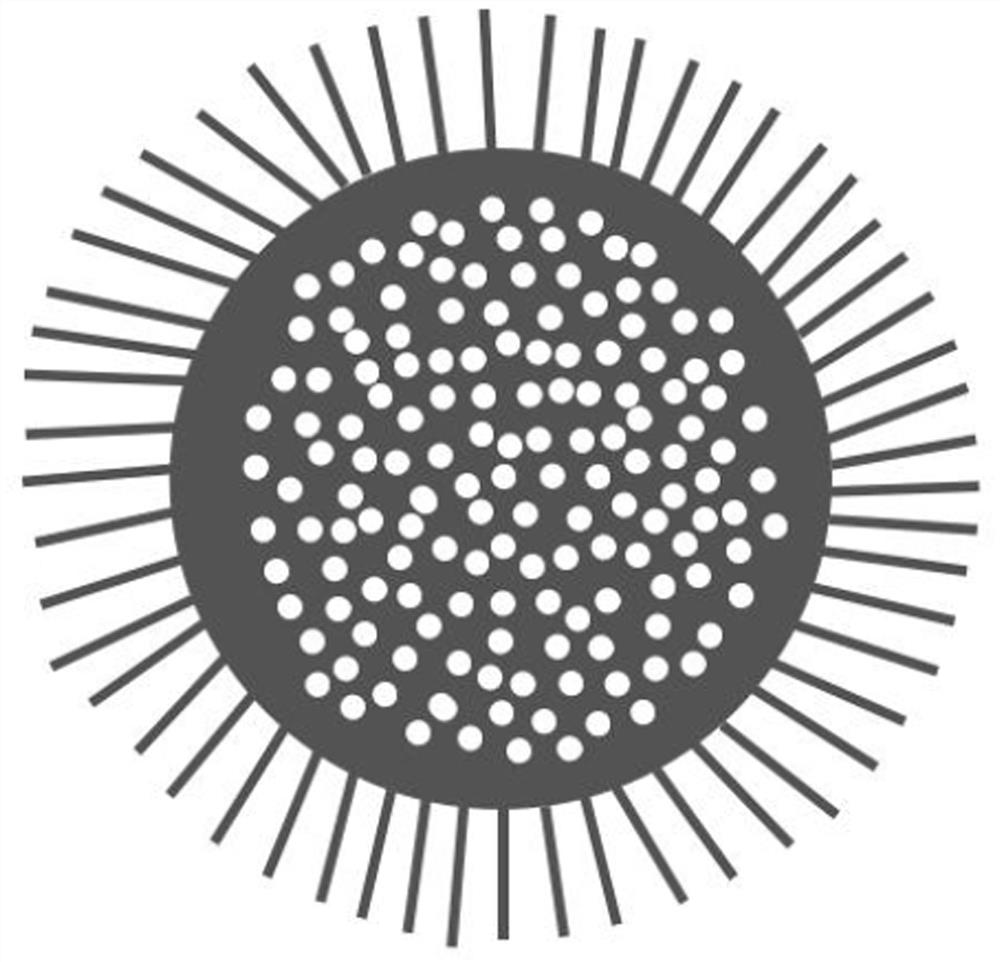

A core-shell structure and cathode material technology, which is applied to nickel-cobalt-manganese core-shell structure precursors and their preparation, and the field of cathode materials, can solve the problems of low tap density of precursors, high content of Na and S in precursors, and poor crystallinity. , to achieve the effect of adjustable core size, wide process application range and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation method of nickel-cobalt-manganese core-shell structure precursor:

[0037] Preparation total metal concentration is the nickel sulfate, cobalt sulfate, manganese sulfate solution of 2mol / L, nickel, cobalt, manganese molar ratio 35:35:30, the sodium hydroxide solution of preparation 2mol / L, the ammonia solution of preparation 6mol / L as Complexing agent. Add pure water to the reactor with a volume of 100L, control the temperature at 40°C, adjust the pH value to 12.0 with alkali, adjust the ammonium ion concentration to 5g / L with ammonia water, and continuously feed nitrogen into the reactor.

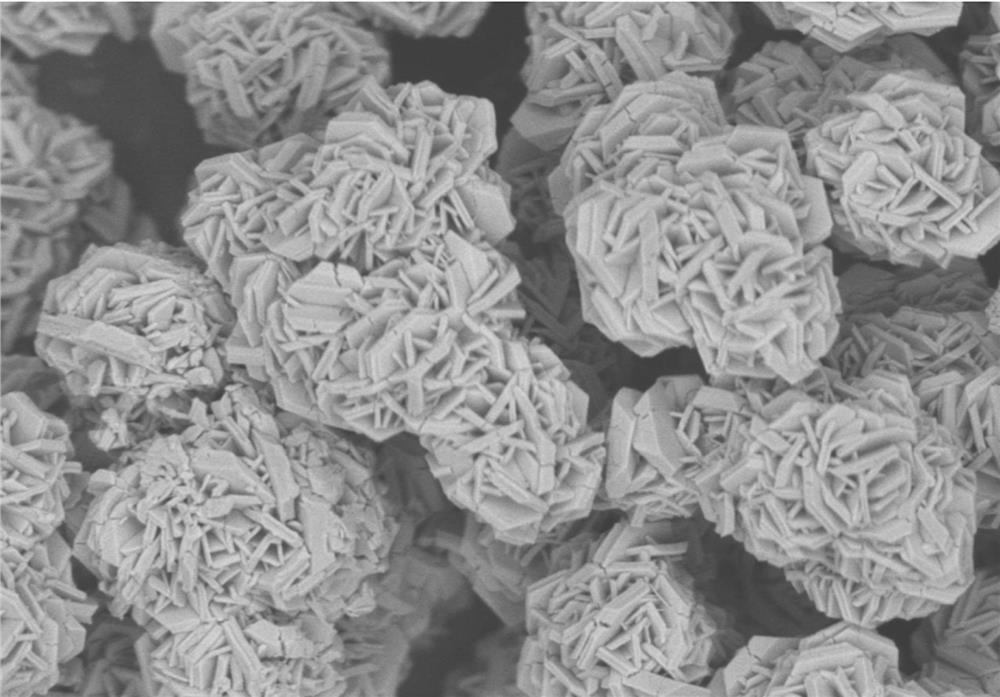

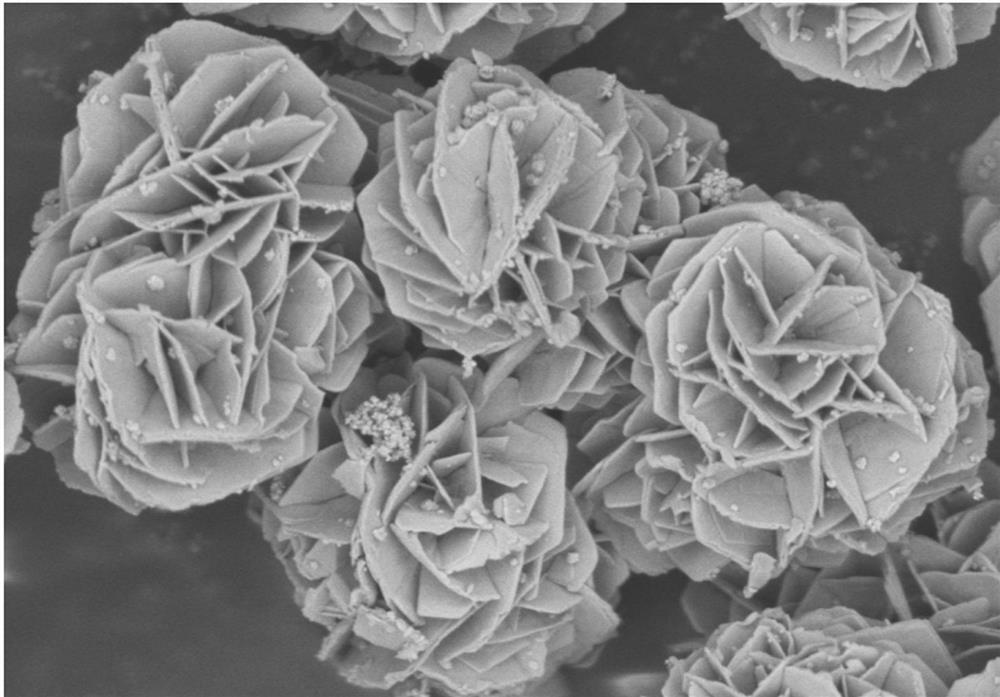

[0038] In the first stage, the pH value is controlled at 11.2-12.0, the linear stirring speed is controlled at 7.0m / s, the metal salt feed flow is controlled at 20mL / min, the ammonium ion concentration is controlled at 5g / L, the temperature is controlled at 40°C, and nitrogen atmosphere, after the precursor particles grow to 2.0 μm, switch the reaction conditions and en...

Embodiment 2

[0040] Preparation method of nickel-cobalt-manganese core-shell structure precursor:

[0041] Prepare the nickel sulfate, cobalt sulfate, manganese sulfate solution that total metal concentration is 2mol / L, nickel, cobalt, manganese mol ratio 50:20:30, prepare the sodium hydroxide solution of 2mol / L, prepare the ammonia solution of 6mol / L as Complexing agent. Add pure water to the reactor with a volume of 100L, control the temperature at 60°C, adjust the pH value to 12.0 with alkali, adjust the ammonium ion concentration to 5g / L with ammonia water, and continuously feed nitrogen into the reactor.

[0042] In the first stage, the pH value was controlled at 11.3-12.0, the linear stirring speed was controlled at 5.5m / s, the metal salt feed flow rate was controlled at 30mL / min, the ammonium ion concentration was controlled at 5g / L, the temperature was controlled at 60°C, and nitrogen atmosphere, after the precursor particles grow to 3.0 μm, switch the reaction conditions and enter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com