Sulfur-containing and bismuth-containing free cutting stainless steel and preparation method thereof

An easy-cutting, stainless steel technology, applied in the direction of furnace types, furnaces, electric furnaces, etc., can solve the problems of poor steel processing performance and failure to mass produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

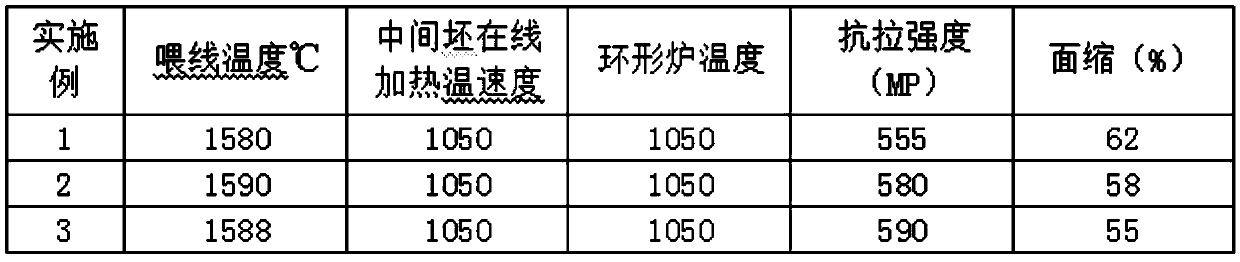

Examples

Embodiment Construction

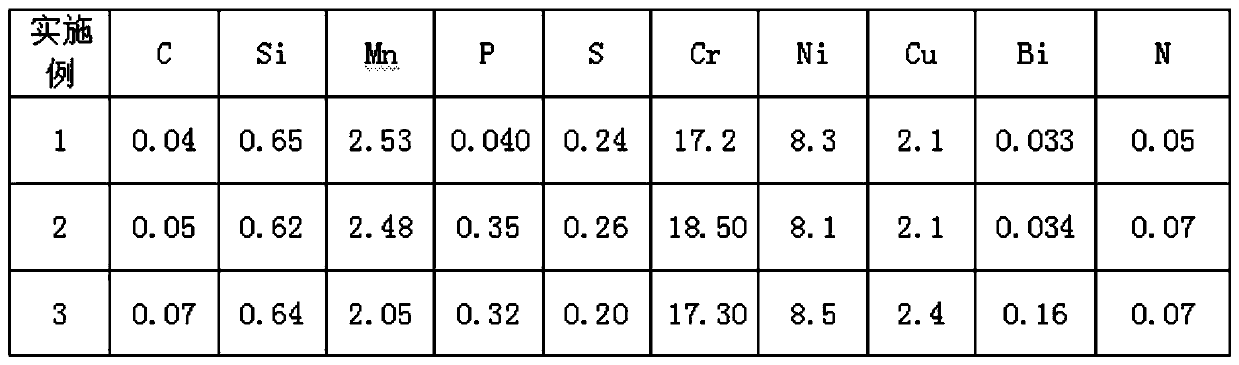

[0014] The sulfur-containing and bismuth-containing free-cutting stainless steel (303CuB) of the present invention, by weight percentage, comprises:

[0015] C: ≤0.08%, Si: 0.5~1.0%, Mn: 2.0~3.0%, P≤0.06%, S: 0.20~0.35%, Ni: 8.5~1.0%, Cr: 17.0~19.0%, Cu: 2.0~ 3.0%, Bi: 0.02-0.2%, N: ≤0.07%, and the rest are iron and unavoidable impurities.

[0016] Among them, carbon is an element that strongly forms austenite in austenitic stainless steel, which can stabilize and expand the austenite phase region and increase the hot workability of austenitic stainless steel. High carbon can significantly improve the solid solution of austenitic stainless steel Strength increases the tendency of pitting corrosion of austenitic stainless steel, so C is controlled at 0-0.08%.

[0017] Chromium can promote the passivation of austenitic stainless steel and maintain a stable passivation state, improve the resistance of steel to oxidizing media and acid chloride media, and improve the resistance o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com