Patents

Literature

40 results about "Eco Pickled Surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

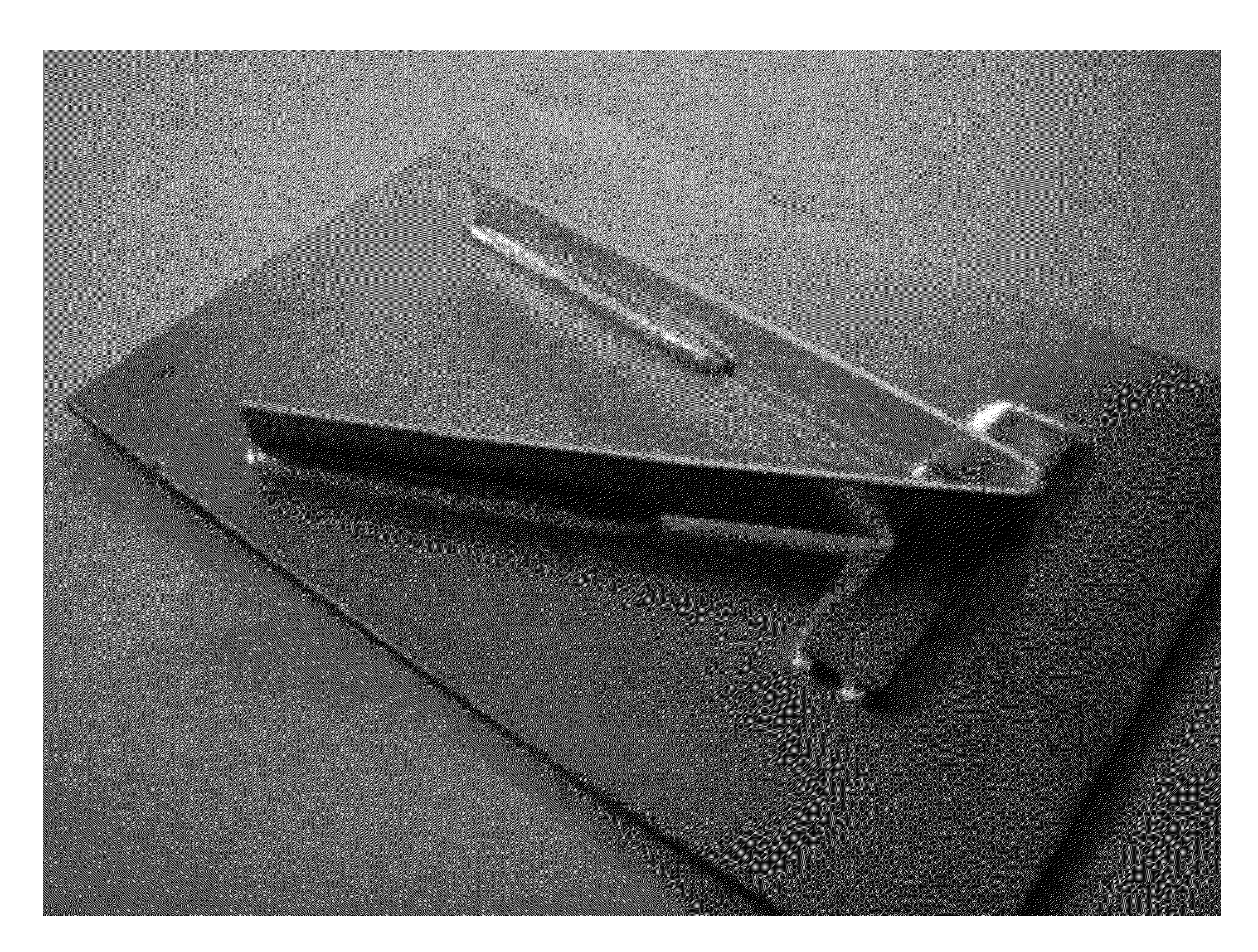

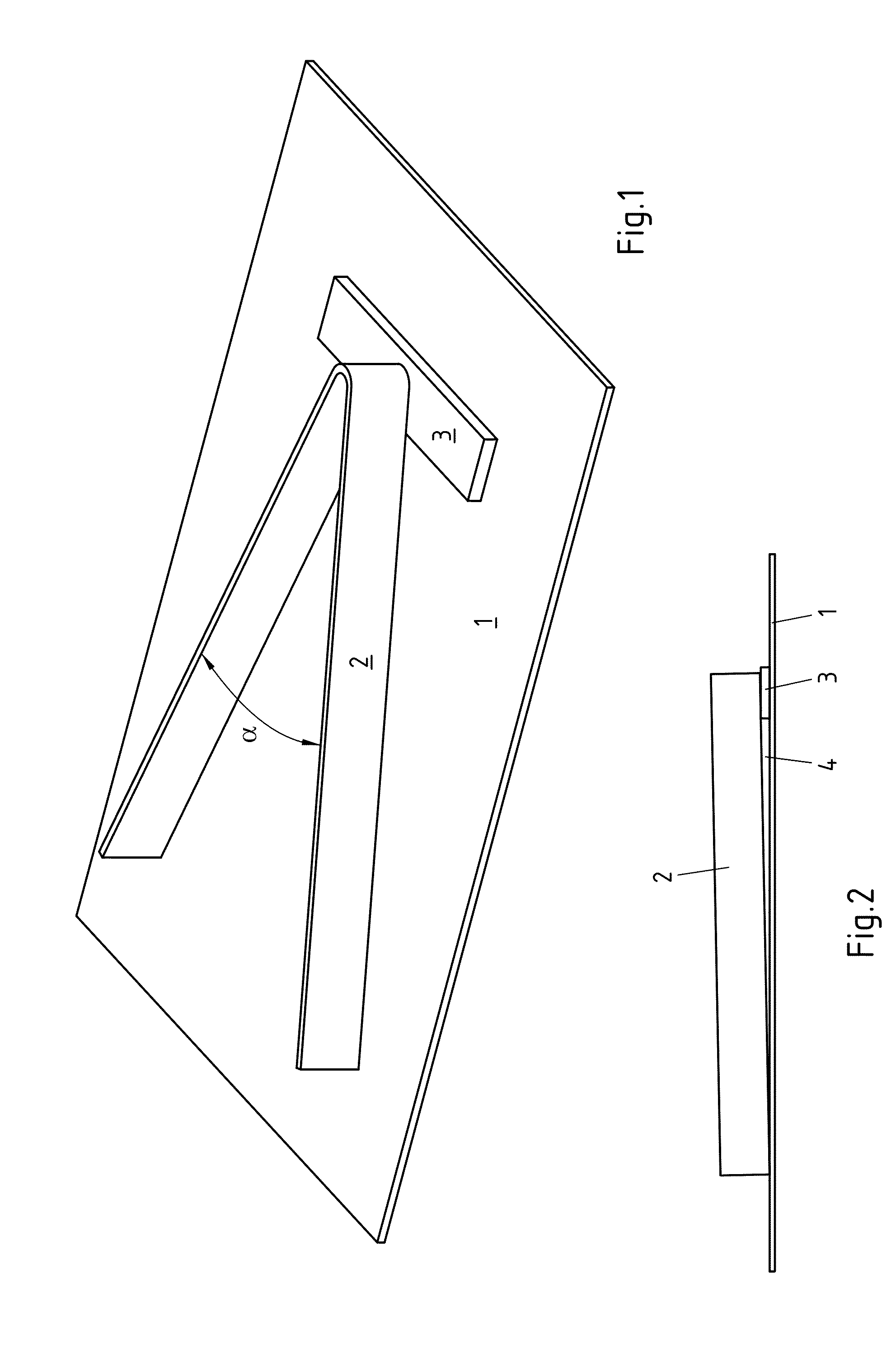

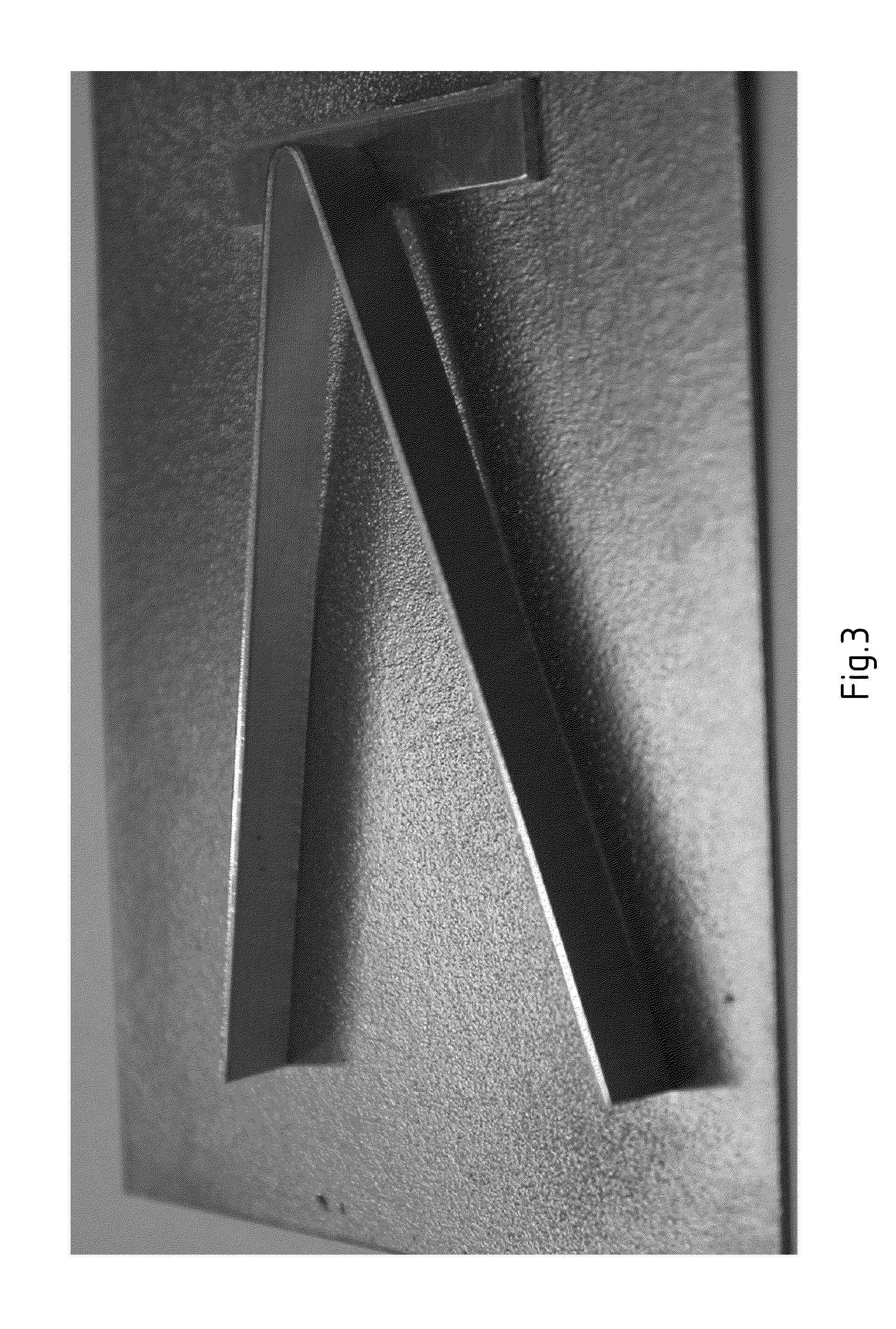

Eco pickled surface (EPS) is a process applied to hot rolled sheet steel to remove all surface oxides (mill scale) and clean the steel surface. Steel which has undergone the EPS process acquires a high degree of resistance to subsequent development of surface oxide (rust), so long as it does not come into direct contact with moisture. EPS was developed by The Material Works, Ltd., which has filed several patent applications covering the process. It is primarily intended to be a replacement of the familiar acid pickling process wherein steel strip is immersed in solutions of hydrochloric and sulfuric acids to chemically remove oxides.

Aluminium Composite Material for Fluxless Brazing

InactiveUS20150053751A1Increased durabilityLow production costFoundry mouldsWelding/cutting media/materialsShielding gasProduct gas

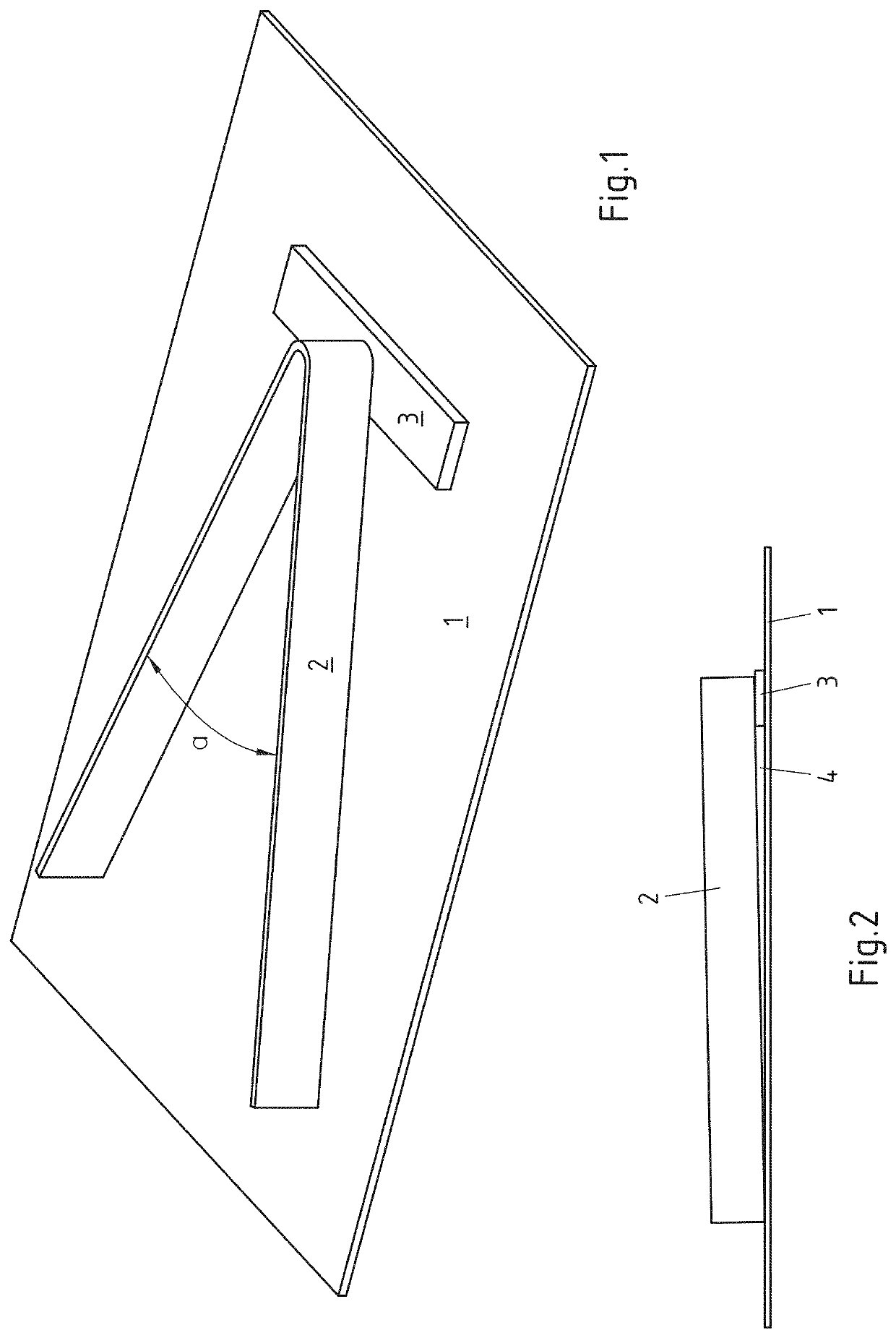

Use of an aluminium composite material consisting of at least one aluminium core alloy and at least one outer brazing layer consisting of an aluminium brazing alloy provided on one or both sides of the aluminium core alloy. Based on this prior art the object of the present invention is to provide a thermal joining process for an aluminium composite material, so that the use of fluxes can be dispensed with, this object being achieved in that the aluminium brazing layer of the aluminium composite material has a pickled surface and the aluminium composite material is used in a fluxless thermal joining process and the joining process is carried out in the presence of a protective gas.

Owner:HYDRO ALUMINIUM ROLLED PROD GMBH

Carbide-enhanced type invar alloy wire and preparing method thereof

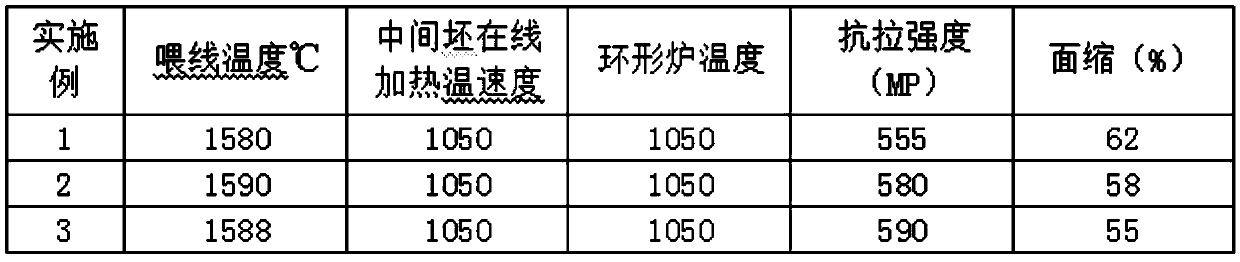

The invention relates to a carbide-enhanced type invar alloy wire and a preparing method thereof. The wire is mainly prepared from, by mass, 0.05-0.2% of C, 34-38% of Ni, smaller than or equal to 0.005% of S, smaller than or equal to 0.005% of P, 0.015-0.04% of Al, 0.1-3.5% of carbide forming elements and the balance Fe and inevitable impurities. The preparing method comprises the steps that the alloy components are prepared into a cast ingot through smelting and casting of a vacuum melting furnace, the cast ingot is forged into a round stick, the round stick is subjected to hot rolling to form a wire rod, the wire rod is subjected to cold drawing to form a wire body, and the wire body is subjected to aging heat treatment, surface acid pickling, surface finishing and other procedures. The carbide-enhanced type invar alloy wire and the preparing method thereof have the advantages that alloy raw materials are saved, the technological process is simplified, and production cost is reduced. The tensile strength of the produced alloy wire is higher than or equal to 1000 MPa, the coefficient of thermal expansion within the range of minus 100-200 DEG C is smaller than or equal to 2.6*10<-6> / DEG C, and the performance requirement of up-rating wire core products is met.

Owner:HEBEI IRON AND STEEL

Pickling method for hot rolled double-phase stainless steel plates

Provided is a pickling method for hot rolled double-phase stainless steel plates. According to the invention, pickling with two mixed acids is utilized; a mixed solution of HNO3 and HF is used for pickling both in a prepickling stage and a final pickling stage, wherein, in the prepickling stage, a prepickling solution comprises 140 to 180 g / l of HNO3 and 80 to 100 g / l of HF, the content of metal ions in acids is 5 to 40 g / l, in the final pickling stage, a final pickling solution comprises 200 to 280 g / l of HNO3 and 55 to 75 g / l of HF, and the content of metal ions in acids is 5 to 40 g / l; thesteel plates are subjected to the steps of prepickling and final pickling for 11.3 to 34 minutes. The invention enables on-line pickling time for each steel plate to be shortened to no more than 10 minutes, production efficiency to be greatly improved and pickling surface quality to meet on-site requirements and requirements of users; in the invention, steel plates continuously move forward on a roller way and do not need to swing to and fro, and the special process of passivation treatment is left out, thereby substantially reducing production cost.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

Flux-free Joining of Aluminium Composite Materials

ActiveUS20160325367A1Shorten treatment timeImprove responseWelding/cutting media/materialsWelding/soldering/cutting articlesShielding gasProduct gas

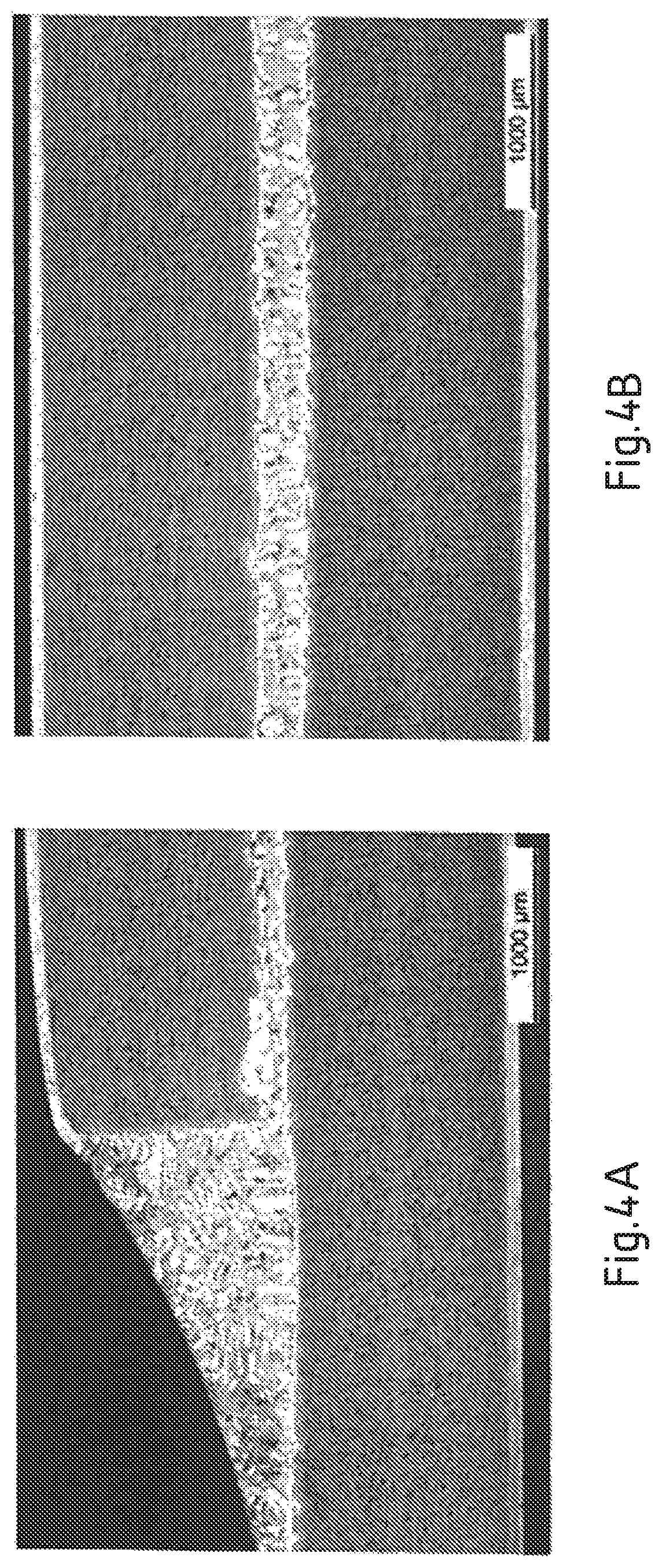

Use of an aluminium composite material in a thermal joining method, said material consisting of at least one aluminium core alloy and at least one external brazing layer consisting of an aluminium brazing alloy provided on one or both sides of the aluminium core alloy, wherein the aluminium brazing layer has a pickled surface. Reduced costs and a lower environmental impact is achieved by using an aluminium composite material in which the pickled surface of the aluminium brazing layer had been pickled by pickling with an acid, aqueous pickling solution containing at least one mineral acid and at least one complex-forming agent or a complexing mineral acid, wherein the removal of material in the pickling is between 0.05 g / m2 and 6 g / m2, the aluminium composite material is used in a flux-free, thermal joining method, and the joining method is carried out in the presence of a protective gas.

Owner:HYDRO ALUMINIUM ROLLED PROD GMBH

Pickling solution capable of removing hot-rolled corrosion-resisting alloy oxide skin and pickling method thereof

The invention relates to a pickling solution capable of removing hot-rolled corrosion-resisting alloy oxide skin and a pickling method thereof. The pickling solution comprises 10 g / L-60 g / L of sulfuric acid, 90 g / L-120 g / L of hydrochloric acid, 25 g / L-75 g / L of nitric acid and the balance of water by proportioning. The pickling method comprises the following steps of: I. soaking corrosion-resisting alloy which is annealed and is subjected to shot blasting in the pickling solution capable of removing the hot-rolled corrosion-resisting alloy oxide skin and comprising 10 g / L-60 g / L of sulfuric acid, 90 g / L-120 g / L of hydrochloric acid, 25 g / L-75 g / L of nitric acid and the balance of water by proportioning, wherein the soaking temperature is 20-90 DEG C, and the soaking time is 120-1 minute; and II. cleaning the pickled corrosion-resisting alloy by using a nylon brush or a roll brush, and then washing and airing. The pickling solution reduces environmental pollution caused by hydrofluoric acid; and due to application of the pickling method, local corrosion is not easy to generate on the surface of a pickled surface.

Owner:TAIYUAN IRON & STEEL GROUP

High tensile strength hot dip plated steel sheet and method for production thereof

InactiveCN1395623AHigh tensile strengthExcellent alloying propertiesHot-dipping/immersion processesFurnace typesSheet steelElectroplating

A method for producing a high tensile strength hot dip plated steel sheet, which comprises providing a steel sheet having a Si content controlled within a specific range and comprising Nb and one or more of Cu, Ni and Mo, subjecting a rolled sheet to a recrystallization annealing to thereby form an inner oxide layer close under the surface of the steel plate, washing the surface with an acid to remove the oxides having been formed also on the surface, heating the resultant steel sheet prior to plating, and then subjecting the sheet to a hot dip plating. The inner oxide layer formed during annealing acts as a barrier against diffusion of Si, Mn and the like during the heat treatment prior to plating, which results in marked reduction of the formation of oxides of Si, Mn and the like. Accordingly, the method can be used for producing a high tensile strength hot dip plated steel sheet which exhibits markedly excellent plating characteristics.

Owner:JFE STEEL CORP

Silvery bright steel wire acid-washing-free and drawing treatment process

InactiveCN106583476AImprove rust removal effectReduce work hardeningExtrusion cleaning devicesSanderAcid washing

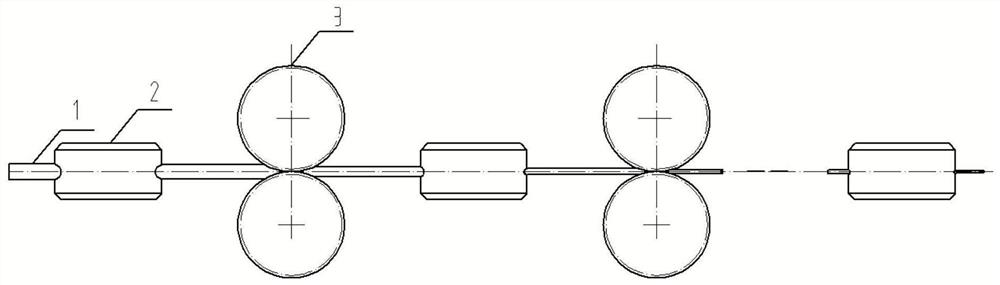

The invention discloses a silvery bright steel wire acid-washing-free and drawing treatment process. The silvery bright steel wire acid-washing-free and drawing treatment process comprises the following steps: (1) mechanically shelling: enabling a wire material to pass through a plurality of rolling wheels which mutually form angles by a mechanical rust-removing device; (2) brushing, sweeping and polishing: increasing a belt sander after the wire material is mechanically shelled and before the wire material enters a mould box, and brushing, sweeping and polishing residual oxide on the surface of the wire material as required; and (3) drawing: adopts a rolling and drawing mould and a pressure mould to cooperate with each other. Through mutual cooperation of the rolling wheels and the belt sander, the rust-removing effect of the wire material is obviously improved and the produced finished product achieves the effect that the surface is silvery bright; meanwhile, the existing acid-washing surface treatment process is replaced, so the production efficiency is improved; and a drawing process which combines the rolling and drawing mould with the pressure mould is adopted, so in the wire material drawn by the process, the processing hardening degree is low, the oxide skin residual ratio is low, the surface flatness is high, the surface lubricating film coverage rate is high, one thin layer of film covers the surface of the wire material, and the subsequent re-processing and cleaning effects are good.

Owner:DONGGUAN KELEE STEEL WIRE

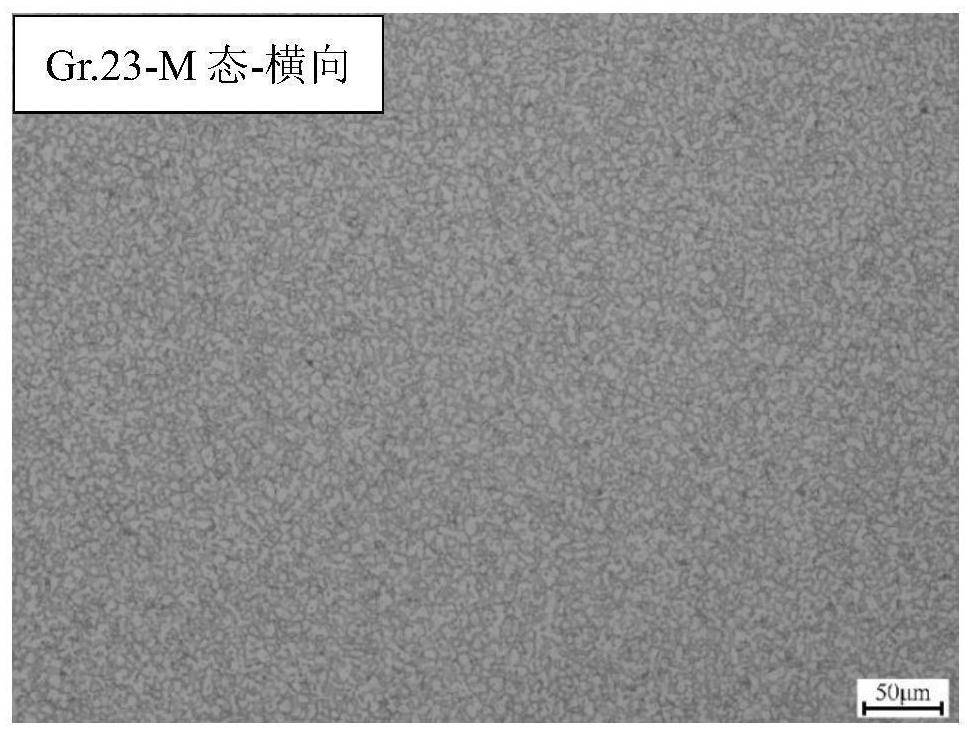

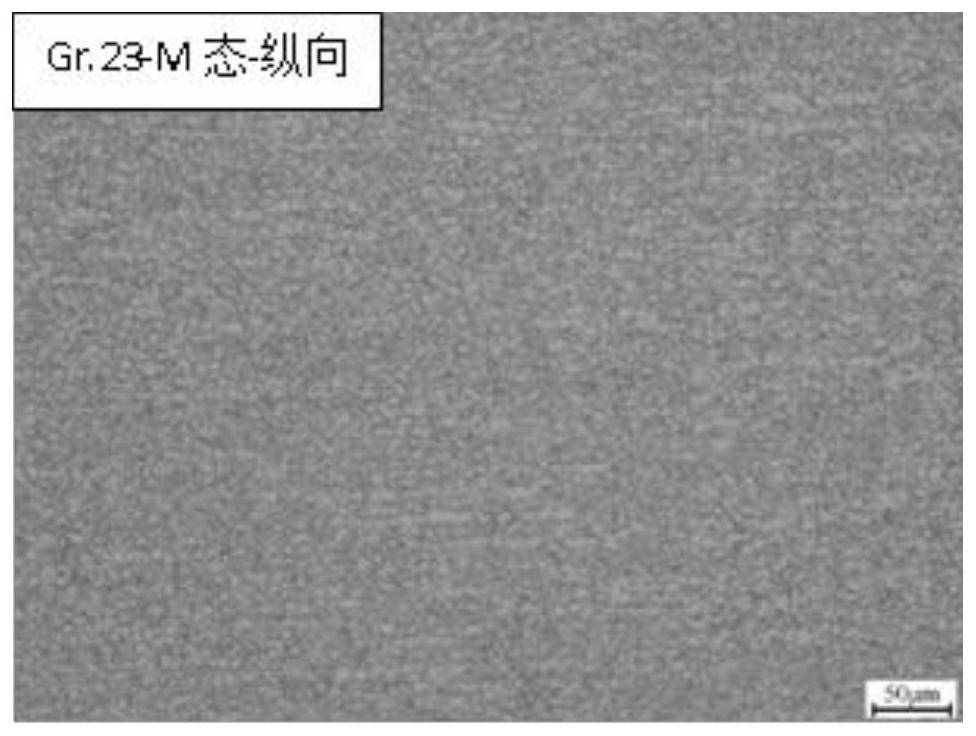

Preparation method of Gr23 titanium alloy wire for powder preparation

ActiveCN111644462AGuaranteed surface purityAvoid passingGrain treatmentsMetal rolling arrangementsSurface oxidationHeating furnace

The invention discloses a preparation method of a Gr23 titanium alloy wire for powder preparation. The preparation method comprises the steps of heating a Gr23 titanium alloy wire blank with uniform transverse and longitudinal structures through a tube heating furnace below the phase transformation point, and conducting multi-pass drawing to obtain a wire blank with the oxidized surface; conducting multi-pass cold drawing on the wire blank through a roller die, and conducting acid pickling through an acid solution to obtain the wire blank without oxide skin, a surface pollution layer and an acid pickling surface; conducting intermediate vacuum annealing on the wire blank to obtain a cold continuous rolled wire blank with the good cold workability; conducting cold continuous rolling on thecold continuous rolled wire blank through twelve square-pore rollers to obtain a special-shaped wire, and conducting cold drawing on the special-shaped wire through a duplex roller die to form a roundwire; and conducting vacuum heat treatment on the wire to obtain the Gr23 titanium alloy wire with the bright surface. The Gr23 titanium alloy wire prepared through the method has no surface oxide skin and surface pollution layer residues, is uniform and fine in transverse and longitudinal structure, is of an equiaxial structure, has the low H content and meets the requirement for raw materials for preparing high-quality spherical powder through a plasma atomization method.

Owner:西部超导材料科技股份有限公司

Continuous pickling method of titanium bands

The invention discloses a continuous pickling method of titanium bands. The method comprises the following steps: pre-cleaning titanium bands obtained after annealing shot blasting, carrying out primary pickling treatment, carrying out intermediate cleaning treatment, carrying out secondary pickling treatment, carrying out final cleaning treatment, and drying, wherein mixed acid solutions used in the primary pickling treatment and the secondary pickling treatment are nitric acid and hydrofluoric acid mixed acid solutions, and the concentrations of nitric acid and hydrofluoric acid in the mixed acid solution used in the primary pickling treatment are different from the concentrations of nitric acid and hydrofluoric acid in the mixed acid solution used in the secondary pickling treatment. The method can improve and control pickling surface quality of the titanium bands, controls the pickling solution loss rate in real time, and realizes the win-win purpose of the pickling surface quality and the rolling yield of the titanium bands.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Production process for nuclear high-quality stainless steel medium-thickness plate

InactiveCN110923726AAvoid roughnessAvoid scratchesFurnace typesHeat treatment furnacesSolution treatmentSurface roughness

The invention discloses a production process for a nuclear high-quality stainless steel medium-thickness plate, and the production process specifically comprises the following steps of smelting, rolling, pickling, surface visual detection, unqualified product grinding and flaw detection, solid-solution treatment, pickling, surface visual detection and qualified product marking. According to the production process disclosed by the invention, pickling is firstly performed on a hot-rolled steel plate after a rolling process, and secondary oxide iron scale generated in the rolling process is removed, so that scratches and press-in defects generated on the lower surface of the steel plate in links such as a transportation roller path, a cold bed, offline transportation and transportation afterrolling is ended are avoided, the number of pickling times after solid-solution treatment is reduced, and the occurrence of a surface roughness phenomenon of the steel plate after pickling is avoided;a stainless steel product produced by the production process is good in surface quality, is uniform in color and luster, is high in product once qualification rate and demand rate, and greatly improves steel plate pickling efficiency and surface quality; and with the adoption of the production process, the once qualification rate of the steel plate is increased to be 95% or higher from 70%, the number of steel plates needing re-pickling is reduced, and production continuity and product quality stability can be guaranteed.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

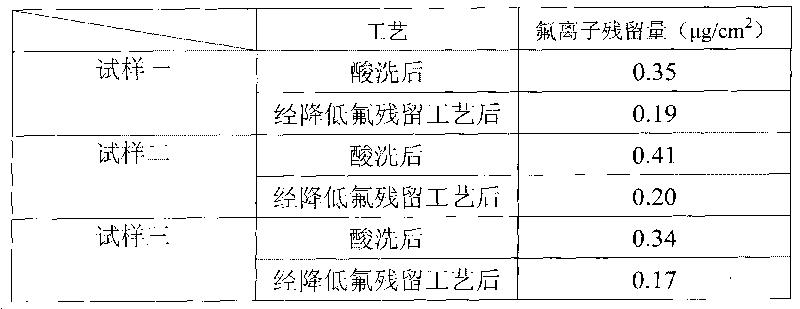

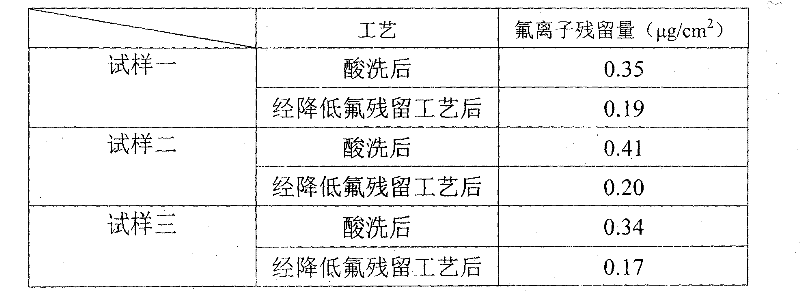

Technology for reducing fluorin residue on acid cleaned surface of zirconium alloy pipe

ActiveCN101698941AReduce fluorine residueExtended service lifeCleaning using liquidsManufacturing technologySoftened water

The invention relates to the field of a technology for reducing fluorin residue on the acid cleaned surface of a zirconium alloy pipe, comprising the following steps: sequentially rinsing the zirconium alloy pipe with NH4CO3 solution and NaOH solution; rinsing the zirconium alloy pipe with hot softened water, and washing the zirconium alloy pipe with cold softened water; and blowing and scrubbing the zirconium alloy pipe by directly blowing with high-pressure gas or blowing and beating the surface of a sponge block to lead the surface of the zirconium alloy pipe to have no moisture and water print remnant to complete the process of reducing the fluorin residue on the acid cleaned surface of the zirconium alloy pipe. The invention can effectively reduce the fluorin residue which mainly is zirconium fluoride complex on the acid cleaned surface of the zirconium alloy pipe, improves the service life of the zirconium alloy pipe, sufficiently meet the use requirement of the zirconium alloy pipe in nuclear power, improves the manufacture technology of the zirconium alloy pipe in China, and enhances the use safety of nuclear materials.

Owner:国核宝钛锆业股份公司 +1

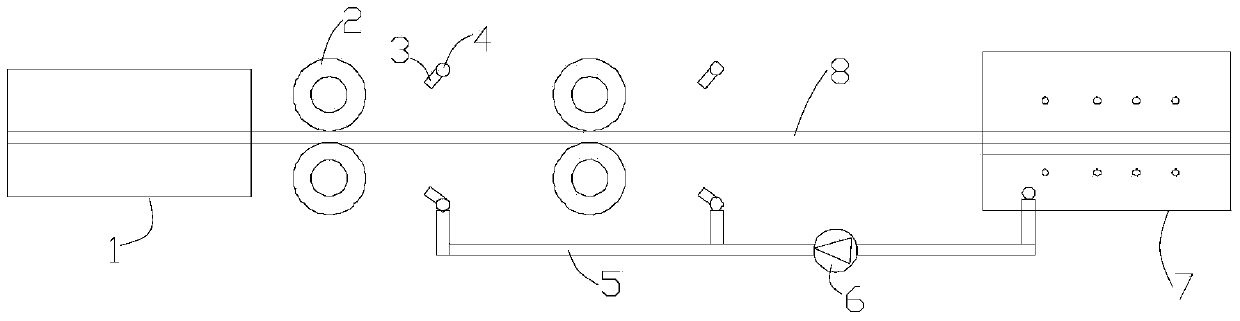

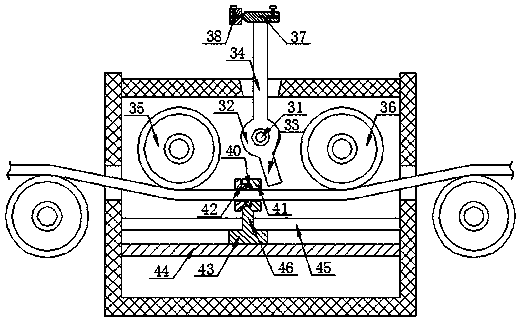

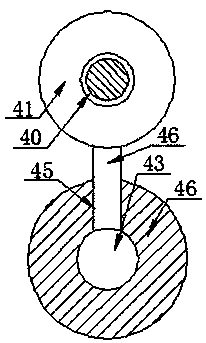

Surface watermark control device for acid pickling of hot-rolled strip steel and watermark control method

The invention discloses a surface watermark control device for an acid pickling of a hot-rolled strip steel and a watermark control method, the two of which are applied to preventing marks from being formed on the surface of the strip steel. The device comprises an acid pickling tank and a rinse tank, wherein a plurality of groups of wiping rolls arranged at intervals are arranged between the acid pickling tank and the rinse tank; a support is arranged between one group of wiping rolls corresponding to the outlet of the acid pickling tank, and the rinse tank; a plurality of nozzles for spraying acidic rinsing water to the strip steel are mounted on the support; the nozzle are connected with a water source through a water delivery pipeline. The rinse tank can be used as the water source; a rinsing water pump is mounted on the water delivery pipeline. Besides, the plurality of nozzles are arranged above and under the strip steel, respectively. The method is characterized in that the acidic rinsing water is sprayed to the surface of the strip steel mainly through the nozzles and the amount of spraying is 2-30 ml / m<2>.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

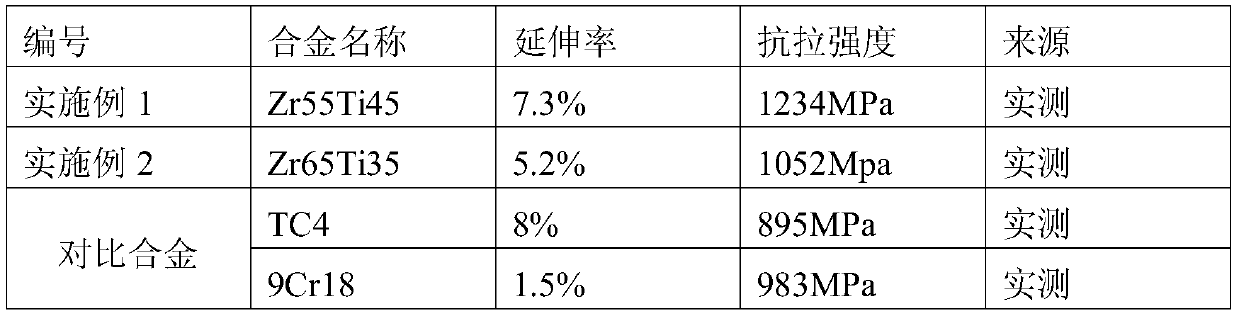

High-performance zirconium-titanium binary alloy and preparation method thereof

The invention discloses a high-performance zirconium-titanium binary alloy and a preparation method of the high-performance zirconium-titanium binary alloy. The zirconium-titanium binary alloy is composed of, by atomic percentage, 55-65% of zirconium and 35-45% of titanium. The preparation method of the high-performance zirconium-titanium binary alloy comprises the following steps that the raw materials are uniformly mixed according to atomic percentage and then the raw materials are put in a non-consumable smelting furnace for smelting, wherein a smelting furnace is filled with argon as a protective atmosphere; the repeatedly smelted ingot is subjected to high-temperature homogenization treatment, and then the ingot is subjected to multi-pass rolling deformation after being heated in a box-type resistance furnace until the deformation amount of the alloy ingot reaches 70%; after the last pass of rolling deformation, the obtained alloy sheet is placed in the atmosphere and cooled to room temperature; and the surface of the alloy sheet cooled to room temperature is subjected to peeling and acid pickling, and the final zirconium-titanium binary alloy is obtained after surface grinding. By the adoption of the high-performance zirconium-titanium binary alloy and the preparation method, the tensile strength of the high-performance zirconium-titanium binary alloy reaches more than 1,052, the elongation can reach more than 7%, compared with the prior art, the high-performance zirconium-titanium binary alloy reaches better comprehensive mechanical properties, and meanwhile, high-performance zirconium-titanium binary alloy has the beneficial effects of low density, good corrosion resistance and the like.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

Titanium belt continuous pickling method

The invention discloses a titanium belt continuous pickling method, and the method comprises the following steps: (1) precleaning, to be more specific, cleaning the upper and lower surfaces of a titanium belt treated by annealing and shot peening; (2) first pickling, to be more specific, using a nitric acid and hydrofluoric acid mixed acid liquid for continuous pickling of the precleaned titanium belt; (3) intermediate cleaning, to be more specific, cleaning the upper and lower surfaces of the firstly pickled titanium belt; (4) second pickling, to be more specific, using the nitric acid and hydrofluoric acid mixed acid liquid for continuous pickling of the intermediately cleaned titanium belt; (5) final cleaning, to be more specific, cleaning the upper and lower surfaces of the secondly pickled titanium belt; and (6) drying, to be more specific, drying the upper and lower surfaces of the finally cleaned titanium belt. The method can improve and control pickled surface quality of the titanium belt, the pickling soluble loss rate can be controlled in real time, and a win-win situation of the pickled surface quality of the titanium belt and yield of the titanium belt can be achieved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Environmental-friendly pickling solution for brass wires and preparation and application method thereof

InactiveCN108359999AGood pickling surface qualityReduce pickling costsEco Pickled SurfaceWater treatment

An environmental-friendly pickling solution for brass wires is characterized by comprising the following components including, by mass concentration ratio, 100 g / L-300 g / L of sulfuric acid, 0.1 g / L-3g / L of corrosion inhibitor, 0.1 g / L-2 g / L of a wetting agent and 0.5 g / L-5 g / L of a brightening agent and further comprises metal sulfate. The metal sulfate comprises ferric sulfate and the balance water, wherein the mass concentration of ferric ions of the ferric sulfate in the pickling solution is 10 g / L-40 g / L. The invention further discloses a preparation and application method of the picklingsolution. Compared with the prior art, the pickling solution has the beneficial effects that the pickling surface quality is good, the pickling metal loss is small, and the pickling cost is low; thepickling solution is suitable for large-batch industrialized pickling of the brass wires; the pickling solution does not contain nitric acid or nitrate, and the problems that in the pickling process,toxic and hazardous gas is generated and nitrogenous waste water treatment is difficult are thoroughly solved; meanwhile, the preparation method of the pickling solution is simple; the application method of the pickling solution is simple, easy to operate and suitable for industrialized large-scale pickling.

Owner:JINTIAN COPPER GROUP CORP NINGBO

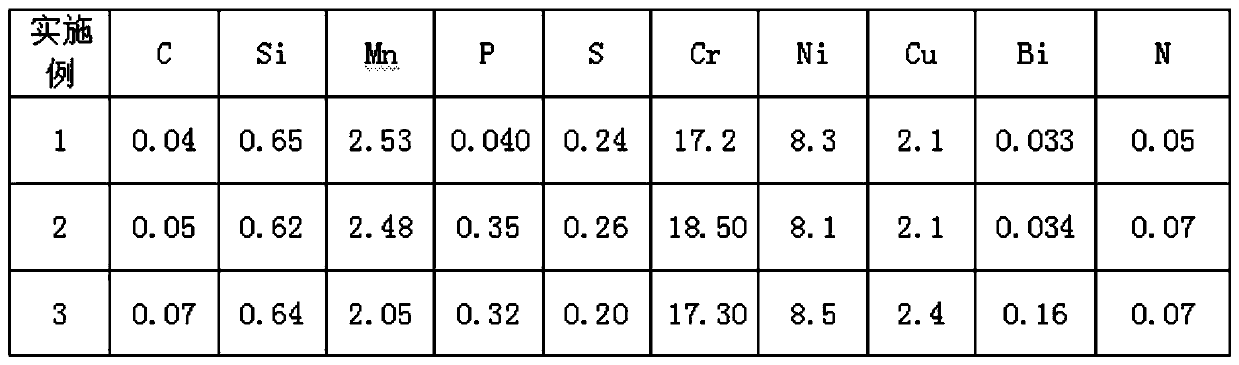

Sulfur-containing and bismuth-containing free cutting stainless steel and preparation method thereof

InactiveCN109825770AGuaranteed surface qualityLow S contentProcess efficiency improvementElectric furnaceWire rodSolid solution

The invention discloses a sulfur-containing and bismuth-containing free cutting stainless steel. The sulfur-containing and bismuth-containing free cutting stainless steel comprises less than or equalto 0.08% of C, 0.5-1.0% of Si, 2.0-3.0% of Mn, less than or equal to 0.06% of P, 0.20-0.35% of S, 8.5-1.0% of Ni, 17.0-19.0% of Cr, 2.0-3.0% of Cu, 0.02-0.2% of Bi, less than or equal to 0.07% of N and the balance of iron and inevitable impurities according to the weight percentage. The invention further discloses a preparation method of the sulfur-containing and bismuth-containing free cutting stainless steel. According to the sulfur-containing and bismuth-containing free cutting stainless steel, by using a method of adding a bismuth element, the cutting performance of a material is improved;by reducing the sulfur content and using an intermediate slab online heating and dry head rolling technology during rolling, a problem that the hot-working character becomes poor due to the adding ofbismuth is solved; solid solution adopts 1050 degrees centigrade complete solid solution process; before acid pickling of a steel wire rod, a problem that the acid pickling surface is easy to be superacid after high temperature treatment is solved through salt bath treatment.

Owner:宝钢特钢长材有限公司

Pickling solution for removing hot-rolled double-phase stainless steel oxide skin and pickling method of pickling solution

The invention provides a pickling solution for removing hot-rolled double-phase stainless steel oxide skin and a pickling method of the pickling solution, and the picking solution can be used for quickly removing the iron oxide skin on the surface of a hot-rolled double-phase stainless steel strip better. The picking method comprises the following steps: preparing the pickling solution by sequentially mixing hydrochloric acid, nitric acid and hydrofluoric acid to obtain a mixture, and standing the mixture for about half an hour after lightly mixing the mixture for about 1-2 minutes, wherein the pickling solution consists of the following components in parts by mass: 2-3 parts of hydrochloric acid with concentration being 36%-38%, 1 part of nitric acid with the concentration being 65%-68%, and not less than 1 part of hydrofluoric acid with the concentration being 40%; completely soaking a hot-rolled double-phase stainless steel sample into the prepared pickling solution for pickling for 20-35 minutes, observing the oxide skin removal condition of a plate surface, and taking out the plate surface when the oxide skin almost drops; and under tap water, clearing the residual iron oxide skin attached to the plate surface by use of a banister brush, then, flushing the plate surface for 1-2 minutes by use of hot water, quickly blow-drying the plate surface by use of an air blower, thereby obtaining a pickled solution with better degree of finish.

Owner:ZHENSHI GROUP EASTERN SPECIAL STEEL

Method for reducing roughness of hot-rolled pickled surface of 10Cr17 stainless steel

InactiveCN111575452AQuality assuranceControl Surface RoughnessAbrasion apparatusFurnace typesSurface roughnessSS - Stainless steel

The invention discloses a method for reducing the roughness of a hot-rolled pickled surface of 10Cr17 stainless steel. The method comprises the following steps that 1, annealing of a steel coil is performed, wherein cover annealing treatment is performed on a hot-rolled 10Cr17 stainless steel black skin coil, the annealing temperature is 760-850 DEG C, and the heat preservation time is 18-22 hours; 2, the shot blasting process is performed, wherein through a shot blasting machine striking angle test, the striking angle of a shot blasting head is adjusted to enable a shot blasting striking surface to be uniformly distributed on the steel strip, and the rotating speed on a transmission side is adjusted to be 25-30Hz, the rotating speed on an operation side is adjusted to be 33-38Hz; and 3, sulfuric acid and mixed acid pickling is performed, wherein sulfuric acid and mixed acid pickling is performed on the shot-blasted steel strip, the concentration of sulfuric acid is 200 g / L-280 g / L, and the concentration of hydrofluoric acid in mixed acid liquor is 0.5 g / L-1.5 g / L. The method can effectively control the surface roughness Ra of the steel strip to be less than or equal to 3.5 micronsso as to solve the contradiction problem between the pickling quality and the surface roughness of the steel strip.

Owner:SHANDONG TAISHAN STEEL GROUP

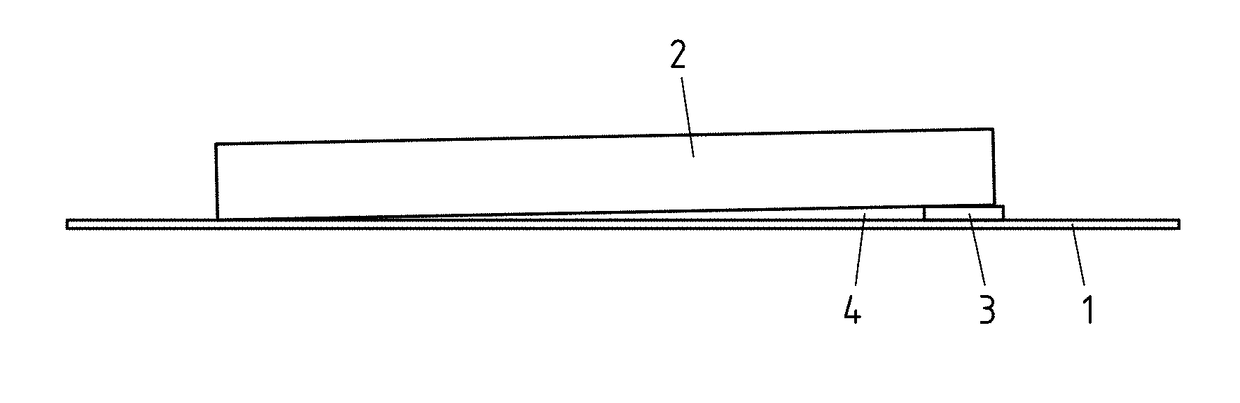

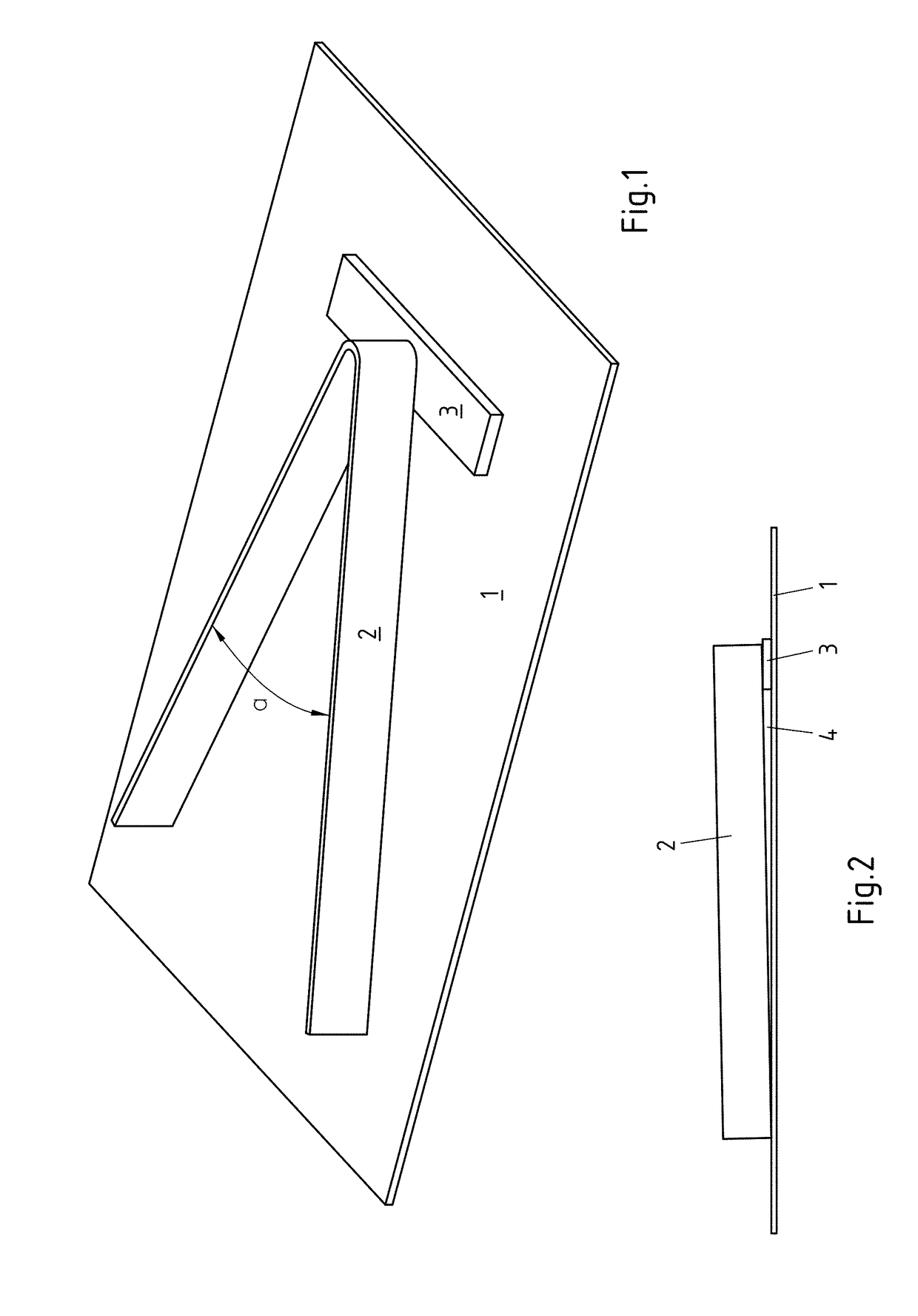

Aluminium composite material for use in thermal flux-free joining methods and method for producing same

InactiveUS20180222151A1Raise the gradeSufficient contentLamination ancillary operationsLayered product treatmentHot meltAluminum composites

Provided are embodiments of an aluminium composite material for use in thermal flux-free joining methods. The composite material has at least one core layer of an aluminium core alloy and at least one outer solder layer of an aluminium solder alloy. The aluminium solder alloy has the following composition in wt %: 6.5%≤Si≤13%, Fe≤1%, 230 ppm≤Mg≤450 ppm, Bi≤500 ppm, Mn≤0.15%, Cu≤0.3%, Zn≤3%, and Ti≤0.30% with the remainder Al and unavoidable impurities individually at most 0.05%, in total at most 0.15% and the aluminium solder layer has an alkaline pickled or acid pickled surface. The invention further relates to a method for producing an aluminium composite material, a method for the thermal joining of components, and a thermally joined construction.

Owner:HYDRO ALUMINIUM ROLLED PROD GMBH

Efficient acid pickling surface treatment method for high-strength automobile steel series strip steel

InactiveCN109023388AReduce over pickling defectsImprove welding qualityMetallic material coating processesLaser beam welding apparatusMaterials preparationStrip steel

The invention provides an efficient acid pickling surface treatment method for high-strength automobile steel series strip steel. The efficient acid pickling surface treatment method comprises the steps that material preparation is conducted, in the welding process of strip steel which is produced through continuous casting and continuous rolling, small power is used for preheating and annealing,wherein the yield strength of the strip steel is in the level of 500-800 MPa; acid pickling work is conducted, and a corrosion inhibitor and an acid pickling agent with the volume ratio being 0.5-3:1000 are placed in an acid pickling tank; rinsing work is conducted, desalted water in rinsing tanks is added in the rinsing tanks in a gradient acceleration method, and the volume ratio of a passivatorto the desalted water is 0.5-2:1000; and after the strip steel obtained after acid pickling is flattened, rolling is conducted after a tension leveler is used for correcting the plate shape, and a finished product is obtained. The efficient acid pickling surface treatment method for the high-strength automobile steel series strip steel has the beneficial effects that usage is convenient, strip steel surface blacking, insufficient acid pickling and excessive acid pickling can be effectively improved, and the strip steel quality is improved.

Owner:RIZHAO STEEL HLDG GROUP

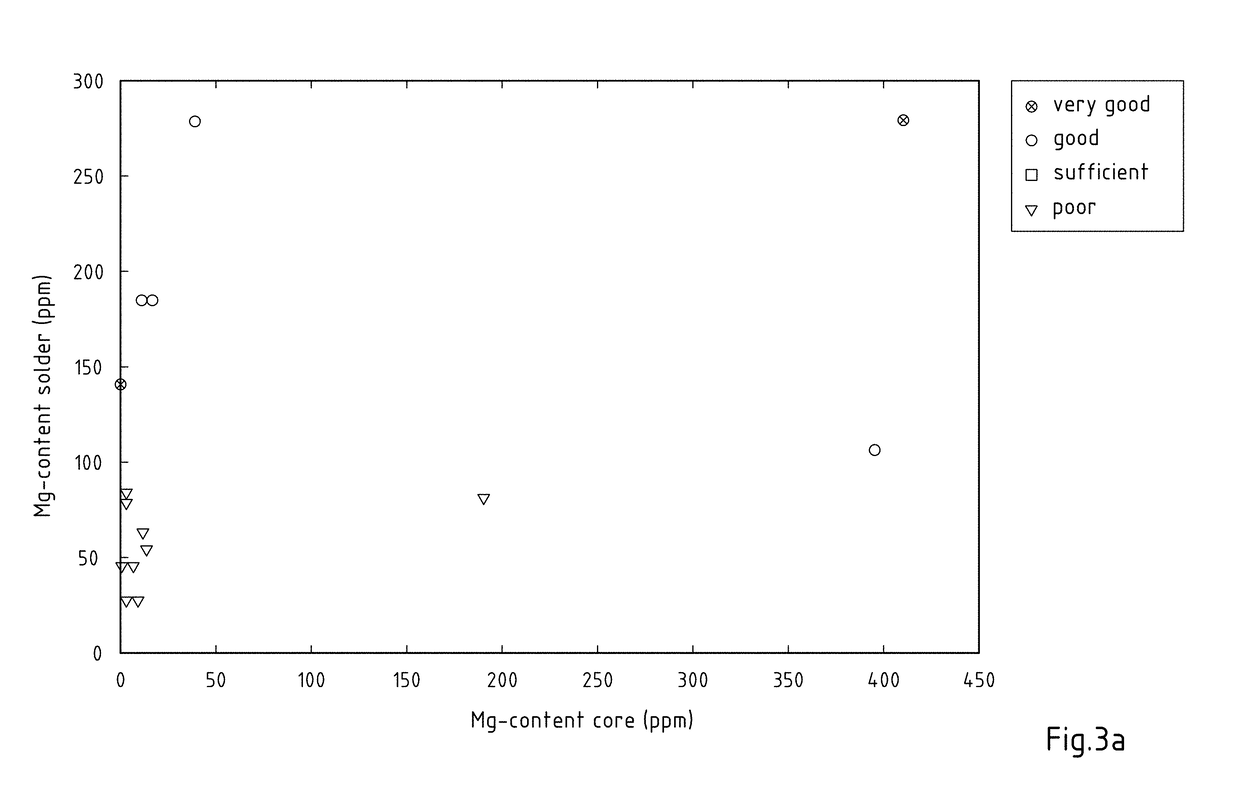

Flux-free joining of aluminium composite materials

ActiveUS10773325B2Outstanding propertyPoor resultWelding/cutting media/materialsWelding/soldering/cutting articlesPickling AgentsAluminum composites

Use of an aluminium composite material in a thermal joining method, said material consisting of at least one aluminium core alloy and at least one external brazing layer consisting of an aluminium brazing alloy provided on one or both sides of the aluminium core alloy, wherein the aluminium brazing layer has a pickled surface. Reduced costs and a lower environmental impact is achieved by using an aluminium composite material in which the pickled surface of the aluminium brazing layer had been pickled by pickling with an acid, aqueous pickling solution containing at least one mineral acid and at least one complex-forming agent or a complexing mineral acid, wherein the removal of material in the pickling is between 0.05 g / m2 and 6 g / m2, the aluminium composite material is used in a flux-free, thermal joining method, and the joining method is carried out in the presence of a protective gas.

Owner:HYDRO ALUMINIUM ROLLED PROD GMBH

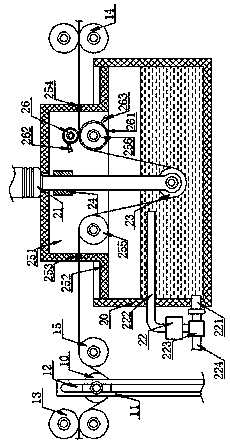

Copper wire production line for detecting and pickling surface grease

The invention discloses a copper wire production line for detecting and pickling surface grease. The copper wire production line comprises a grease detection mechanism and a lifting pickling mechanism. The grease detection mechanism comprises an upstream positioning roller, a downstream positioning roller, a friction force detection ring and a grease detection swing rod; the grease detection swingrod comprises a swing rod mounting shaft, a swing rod mounting sleeve, a swing rod detection part and a swing rod swing part; a moving contact block is fixedly arranged at the upper end of the swingrod swing part, a fixed contact block is arranged on the upstream side of the moving contact block, and a torsional spring is arranged between the swing rod mounting shaft and the swing rod mounting sleeve; the swing rod detection part is positioned at the downstream of the friction force detection ring; the lifting pickling mechanism comprises a pickling tank body and a lifting air cylinder, a piston rod of the lifting air cylinder is arranged downwards, and an immersion roller is arranged at the lower end of the lifting air cylinder. According to the invention, grease detection can be carried out on a copper wire, the copper wire can be immersed in a pickling solution when grease exists, and the copper wire does not contact the pickling solution when the grease does not exist.

Owner:芜湖恒泰有色线材股份有限公司

Pickling method for hot rolled double-phase stainless steel plates

InactiveCN102337547BOnline pickling rhythm time shortenedIncrease productivitySheet steelDouble phase

Owner:BAOSTEEL SPECIAL STEEL CO LTD

High tensile strength hot dip plated steel sheet and method for production thereof

InactiveCN100374585CHigh tensile strengthExcellent alloying propertiesHot-dipping/immersion processesFurnace typesSheet steelElectroplating

Owner:JFE STEEL CORP

Direct chromium stainless-steel pickling agent

The invention relates to a pickling agent for chromium stainless steel, in particular to a direct pickling agent for chromium stainless steel. The method solves the problems that the existing pickling agent for removing chromium stainless steel oxide scale is unreasonable, and thus pretreatment such as alkali bath is required before pickling, resulting in complicated treatment process and poor surface quality after pickling. The composition and weight ratio of the pickling agent are: 30%-80% hydrochloric acid with a concentration of 30%, 17.2%-69.7% hydrofluoric acid with a concentration of 50% or 55%, and 0.3%-3.8% corrosion inhibitor. The corrosion inhibitor can be hexamethylene tetraammonium or rhodin or LK type corrosion inhibitor. The prominent feature of the direct pickling agent for chromium stainless steel is that it can directly remove the scale of chromium stainless steel without pretreatment such as alkali bath, which simplifies the treatment process. Experiments have proved that the pickling agent has excellent protection performance on the surface of chromium stainless steel, and the pickling surface is smooth and white, which is similar to that of austenitic stainless steel. It is suitable for pickling of chromium stainless steel wire, bar, profile, pipe, plate, wire, etc. and mechanical parts in the state of heat processing and heat treatment.

Owner:李青

Technology for reducing fluorin residue on acid cleaned surface of zirconium alloy pipe

ActiveCN101698941BReduce fluorine residueExtended service lifeCleaning using liquidsManufacturing technologySoftened water

The invention relates to the field of a technology for reducing fluorin residue on the acid cleaned surface of a zirconium alloy pipe, comprising the following steps: sequentially rinsing the zirconium alloy pipe with NH4CO3 solution and NaOH solution; rinsing the zirconium alloy pipe with hot softened water, and washing the zirconium alloy pipe with cold softened water; and blowing and scrubbingthe zirconium alloy pipe by directly blowing with high-pressure gas or blowing and beating the surface of a sponge block to lead the surface of the zirconium alloy pipe to have no moisture and water print remnant to complete the process of reducing the fluorin residue on the acid cleaned surface of the zirconium alloy pipe. The invention can effectively reduce the fluorin residue which mainly is zirconium fluoride complex on the acid cleaned surface of the zirconium alloy pipe, improves the service life of the zirconium alloy pipe, sufficiently meet the use requirement of the zirconium alloy pipe in nuclear power, improves the manufacture technology of the zirconium alloy pipe in China, and enhances the use safety of nuclear materials.

Owner:国核宝钛锆业股份公司 +1

Ionic liquid compounded corrosion and fog inhibitor and preparation method and application thereof

ActiveCN112680735AWide liquid rangeImprove thermal stabilityBulk chemical productionFoaming agentIonic liquid

The invention belongs to the technical field of carbon steel pickling, and particularly relates to an ionic liquid compounded corrosion and fog inhibitor and a preparation method and application thereof. The corrosion and fog inhibitor is prepared from the following components in parts by mass: 10-40 parts of ionic liquid, 1-10 parts of a complexing agent, 0.1-1 part of a foaming agent, 0.1-1 part of a foam stabilizer, 0.05-0.1 part of a wetting agent and 60-88 parts of a solvent. Compared with the prior art, the ionic liquid compounded corrosion and fog inhibitor can reduce excessive corrosion to steel in the hydrochloric acid pickling process, the usage amount is small, and the agent cost of pickling is saved; the re-rusting time of the pickled steel is long, and the pickled surface is attractive; and meanwhile, the corrosion and fog inhibitor can also be used as a fog inhibitor to greatly reduce generation of acid fog and reduce environmental pollution, and can be widely applied to the field of hydrochloric acid pickling.

Owner:山东京博众诚清洁能源有限公司

A kind of preparation method of sintered NdFeB sheet magnet

ActiveCN106783131BReduce direct contactReduce material costsInductances/transformers/magnets manufactureMagnetic materialsMetal foilBiological activation

The invention discloses a preparation method of a sintering neodymium iron boron sheet magnet. The preparation method comprises the following steps of manufacturing a sintering neodymium iron boron blank into a sheet blank with thickness of 0.4 to 1.0mm by a mechanical processing technology; when grains at the surface layer of the sheet blank are damaged, cleaning and drying the surface of the sheet blank, packaging a black sheet by a metal bag or metal foil paper, putting into a vacuum sintering furnace, and performing heat treatment under a vacuum state; then, performing vibration, grinding and chamfering, and pickling surface activation. The preparation method has the advantages that excessive noble elements, such as cobalt, dysprosium and terbium, do not need to be added, so that the material cost of a component is hardly increased; the size critical point of the component thinning corresponding to the size fining of the grains is avoided; the cost is lower, the difficulty in technology manufacturing is little, and the degrading of anti-magnetic decay ability caused by damage to the surface grains is relieved.

Owner:NINGBO YUNSHENG +2

Silver plating method for glass mirror

The invention relates to a silver plating method for a glass mirror. The method comprises the steps of: cleaning the glass, sensitizing, super sensitizing, sliver plating, passivating, secondarily passivating, primer painting, primer baking, finish-paint painting, air cooling, surface scouring, indicating cleaning and acquiring finished product, wherein the silver plating process includes a primary silver plating and a secondary silver plating; the primary silver plating is performed before the secondary silver plating; the unit area silver mass on the glass is 100 to 200 mg / m2 after the primary silver plating; the reducing solution in the reaction solution is low speed reaction reducing solution; the unit area silver mass on the glass is 700 to 800 mg / m2 after the secondary silver plating; and the reducing solution in the reaction solution is high speed reaction reducing solution. The invention has the advantages of promoting the reflection ratio of the glass mirror and increasing the thickness.

Owner:江阴市京澄玻璃有限公司

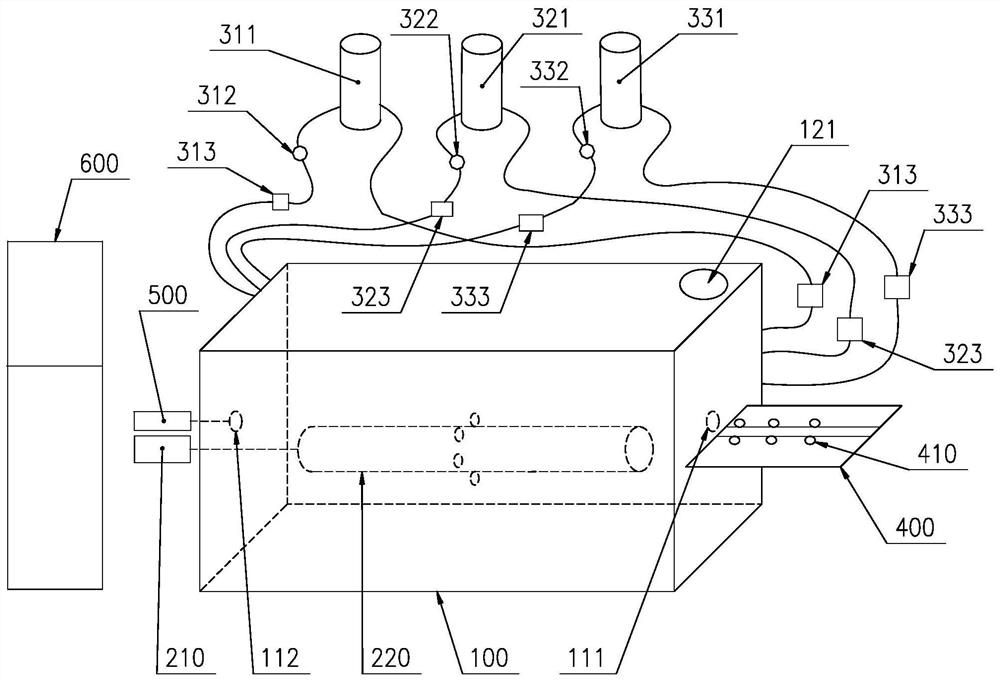

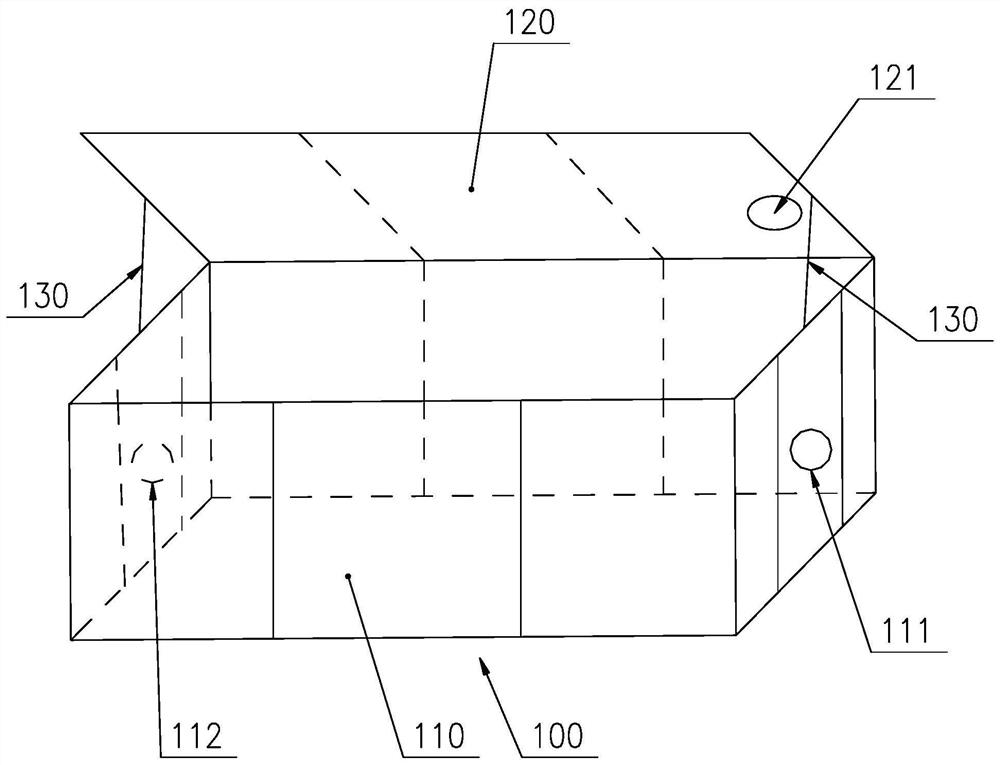

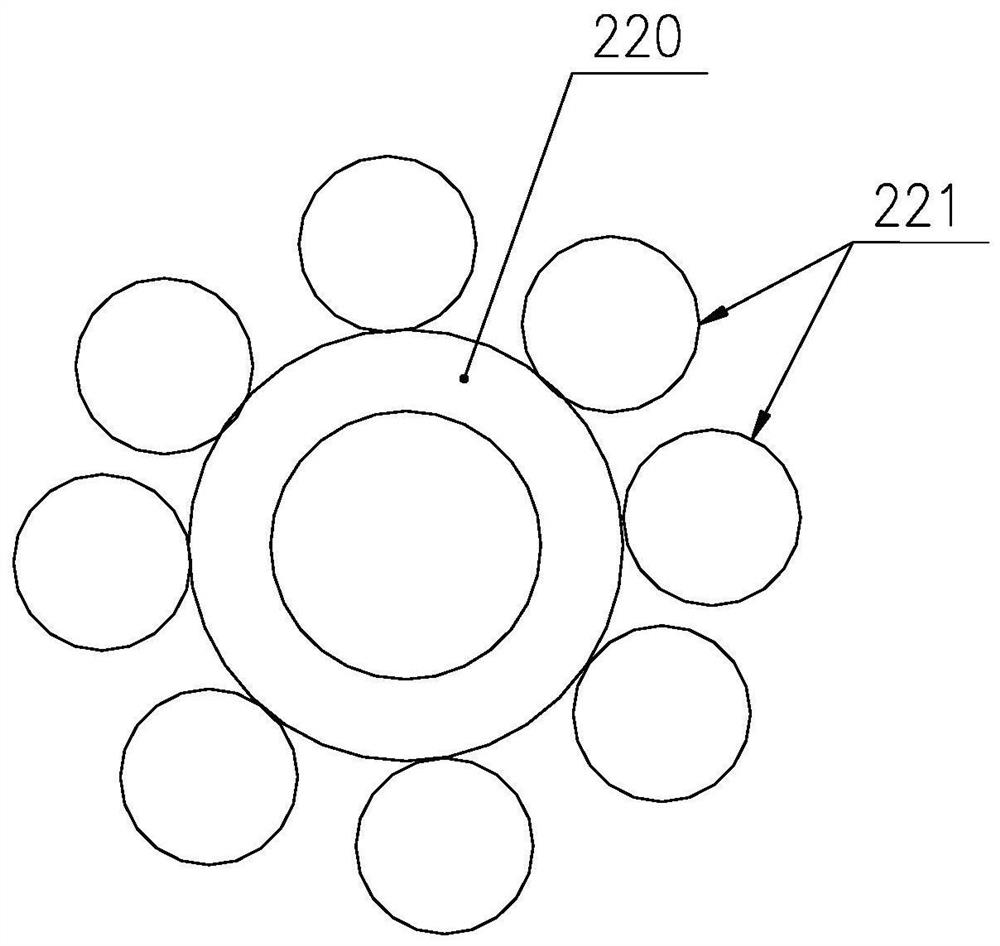

Equipment and method for continuous pickling of titanium and titanium alloy oil pipes

ActiveCN111501054BSimple structureLow costDirt cleaningCleaning using gasesProcess engineeringTitanium

The invention belongs to the field of manufacturing technology, and specifically discloses a device and method for continuous pickling of titanium and titanium alloy oil pipes, which have low safety risks and are beneficial to control the surface quality and size uniformity of oil pipe pickling. The equipment for continuous pickling of titanium and titanium alloy oil pipes includes an equipment box, an actuator, a circulation mechanism and an acid mist collection device. The equipment for continuous pickling of titanium and titanium alloy tubing can fix the tubing on the rotary shaft and drive it to rotate in the equipment box to complete the pickling, neutralization and cleaning steps, which is beneficial to ensure the surface quality and size of the tubing pickling Uniformity; at the same time, the acid liquid, neutralizing liquid and cleaning liquid are pumped separately, which can not only improve the pickling efficiency, but also reduce the labor intensity of workers and reduce the risk of corrosion damage; in addition, during the pickling process, the acid produced The mist can be pumped into the lye tank by the fan through the acid mist discharge hole for neutralization treatment, which avoids the risk of acid mist overflow and meets the environmental protection requirements.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com