Preparation method of Gr23 titanium alloy wire for powder preparation

A technology of titanium alloy wire and wire material, which is applied in the field of titanium alloy processing, can solve the problems of residual scale, elongated longitudinal structure, and difficulty in controlling the surface α pollution layer, etc., and achieve the effect of bright surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method for powder-making Gr23 titanium alloy wire, specifically comprising the following steps:

[0037] Step 1, wire hot drawing:

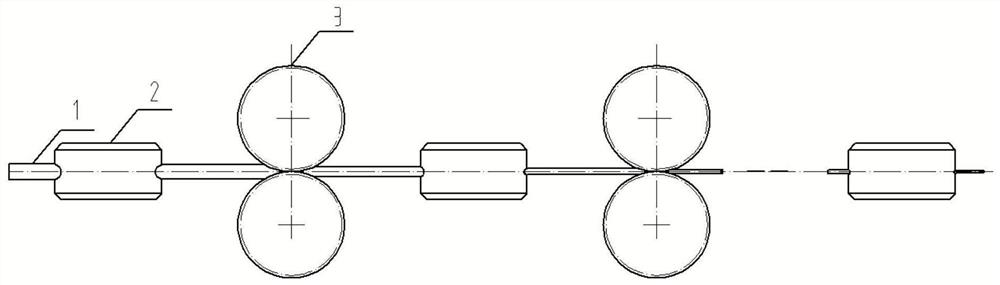

[0038] The annealed Gr23 titanium alloy wire billet (such as figure 1 Shown); heating with a tubular resistance furnace, the heating temperature is below the phase transition point 90 ℃ ~ 130 ℃, the drawing speed is (4 ~ 16) m / min, the hot drawing pass is 4 ~ 6 passes, each The deformation of each pass is 5.5%-20%, and the cumulative deformation of hot drawing is 39.5%-53%. After hot drawing, the R-state cold-drawn wire billet 1 with an oxidized surface is obtained;

[0039] Step 2, roll die cold drawing, pickling:

[0040] For the cold-drawn wire billet 1 obtained in step 1, two passes of cold drawing are adopted with a double roller die, the deformation of each pass is 6% to 9%, and the cumulative deformation of drawing by the roller die is 12% to 17%. After drawing, the oxide scale on the surface of the wire material h...

Embodiment 1

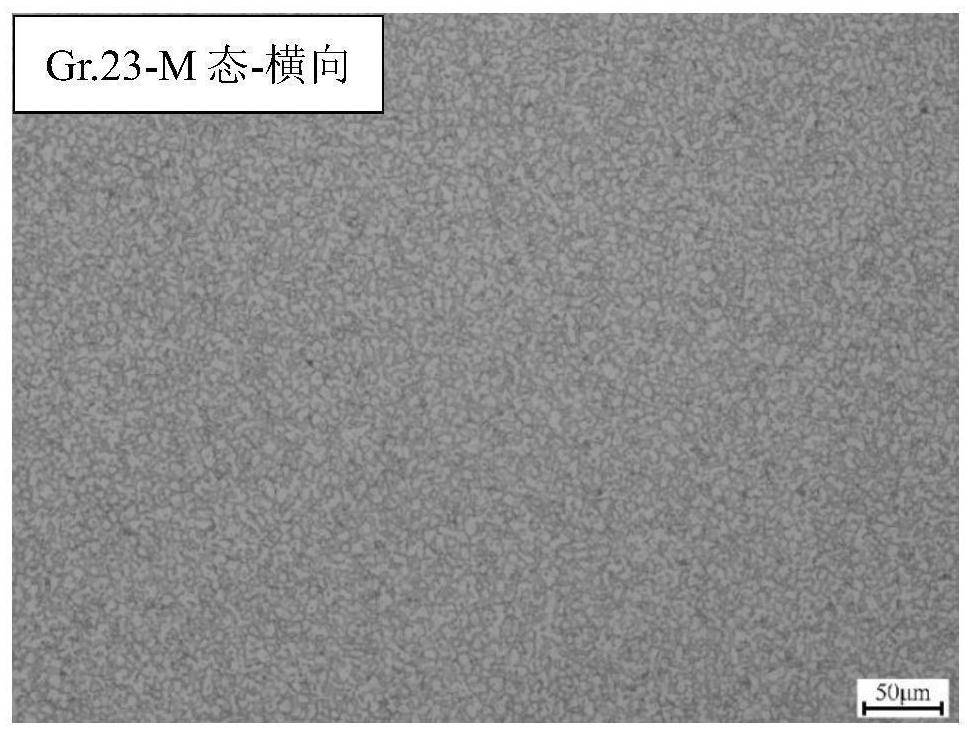

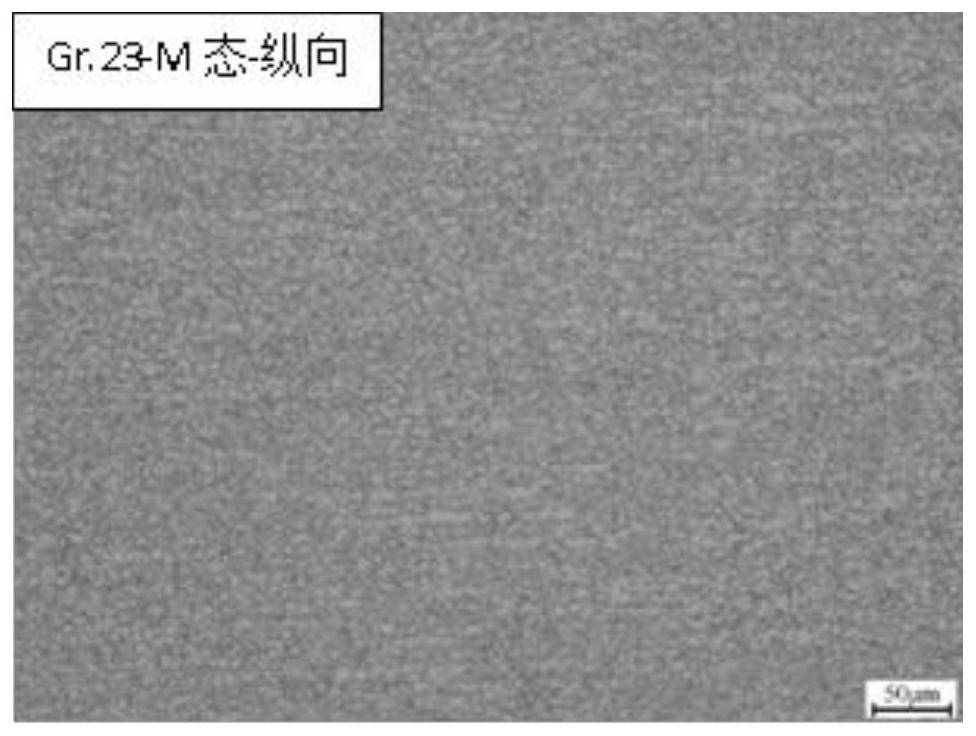

[0049] Step 1: Use an annealed Φ7.5mm Gr23 titanium alloy round wire blank with uniform horizontal and vertical structures, and heat it with a tubular resistance furnace. The heating temperature is 130°C to 120°C below the phase transition point, and the number of hot drawing passes is 5. Passes, the amount of deformation per pass is 9% to 18%, the hot drawing speed is (4 to 6) m / min, and the hot drawing is to Φ5.15mm.

[0050] In step 2, the silk blank obtained in step 1 is cold-drawn for 2 passes with a duplex roller die, and the deformation of each pass is 8% to 9%, and drawn to Φ4.7mm. Cleaning with acid solution after drawing, pickling and its volume ratio HF:HNO 3 :H 2 O=1:2:7. Obtain silk blanks with no scale and no α-pollution layer pickling surface.

[0051] Step 3: Perform intermediate annealing on the Φ4.7mm pickled surface silk blank obtained in step 2 with a vacuum heat treatment furnace. -2 Pa, the holding time is 60min-90min, and the cold continuous rolling ...

Embodiment 2

[0055] Step 1: Use an annealed Φ3.15mm Gr23 titanium alloy round wire billet with uniform horizontal and vertical structures, and heat it with a tubular resistance furnace at a temperature of 120°C to 110°C below the phase transition point, and the number of hot drawing passes is 4. Passes, the amount of deformation in each pass is 10% to 20%, the hot drawing speed is (6~8) m / min, and the hot drawing is to Φ2.275mm.

[0056] In step 2, the silk blank obtained in step 1 is cold-drawn for 2 passes with a duplex roller die, and the deformation of each pass is 7%-8%, and drawn to Φ2.11mm. Cleaning with acid solution after drawing, pickling and its volume ratio HF:HNO 3 :H 2 O=1.2:3:10. Obtain silk blanks with no scale and no α-pollution layer pickling surface.

[0057] Step 3: The Φ2.11mm pickling surface silk billet obtained in step 2 is subjected to intermediate annealing in a vacuum heat treatment furnace, the holding temperature is 715°C-730°C, and the vacuum degree in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com