Surface watermark control device for acid pickling of hot-rolled strip steel and watermark control method

A control device, hot-rolled strip technology, applied in the field of hot-rolled strip steel pickling surface watermark control device, can solve the problems of imprints on the surface of products, affecting product quality, and difficult to clean, so as to ensure the quality of the board surface and prevent imprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

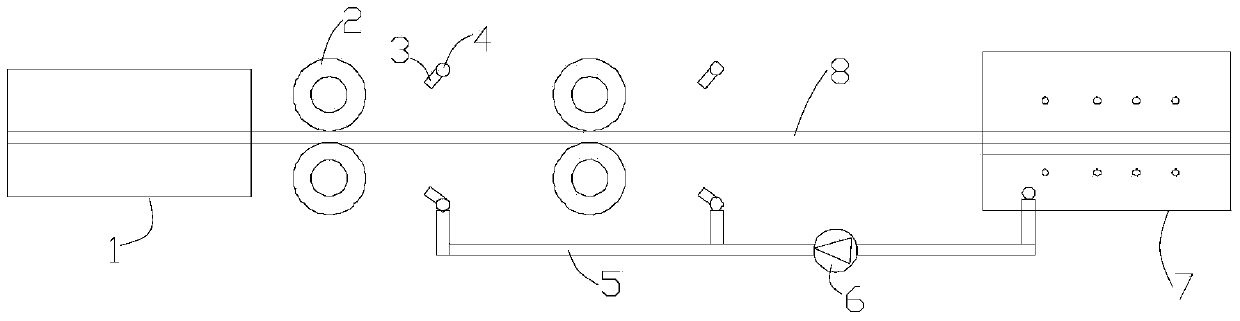

[0018] The hot-rolled strip steel pickling surface watermark control device includes a pickling tank 1 and a rinsing tank 7. There are multiple sets of squeeze rollers arranged at intervals between the pickling tank 1 and the rinsing tank 7. The outlet of the pickling tank 1 corresponds to A supporting frame 4 is arranged between a group of squeezing rollers and the rinsing tank 7, and a plurality of nozzles 3 for spraying acidic rinsing water to the strip are installed on the supporting frame 4, and the nozzles 3 are connected to the rinsing tank 7 through a water supply pipe 5, A rinsing water pump 6 is installed on the water delivery pipeline 5 , and the plurality of nozzles 3 are respectively arranged above and below the steel strip 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com