Flux-free Joining of Aluminium Composite Materials

a technology of composite materials and aluminium, which is applied in the direction of soldering equipment, manufacturing tools, light and heating equipment, etc., can solve the problems of poor brazing results and unnecessarily high material loss, and achieve no significant gain in processing speed, no significant increase in reagent reactivity, and reduced treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

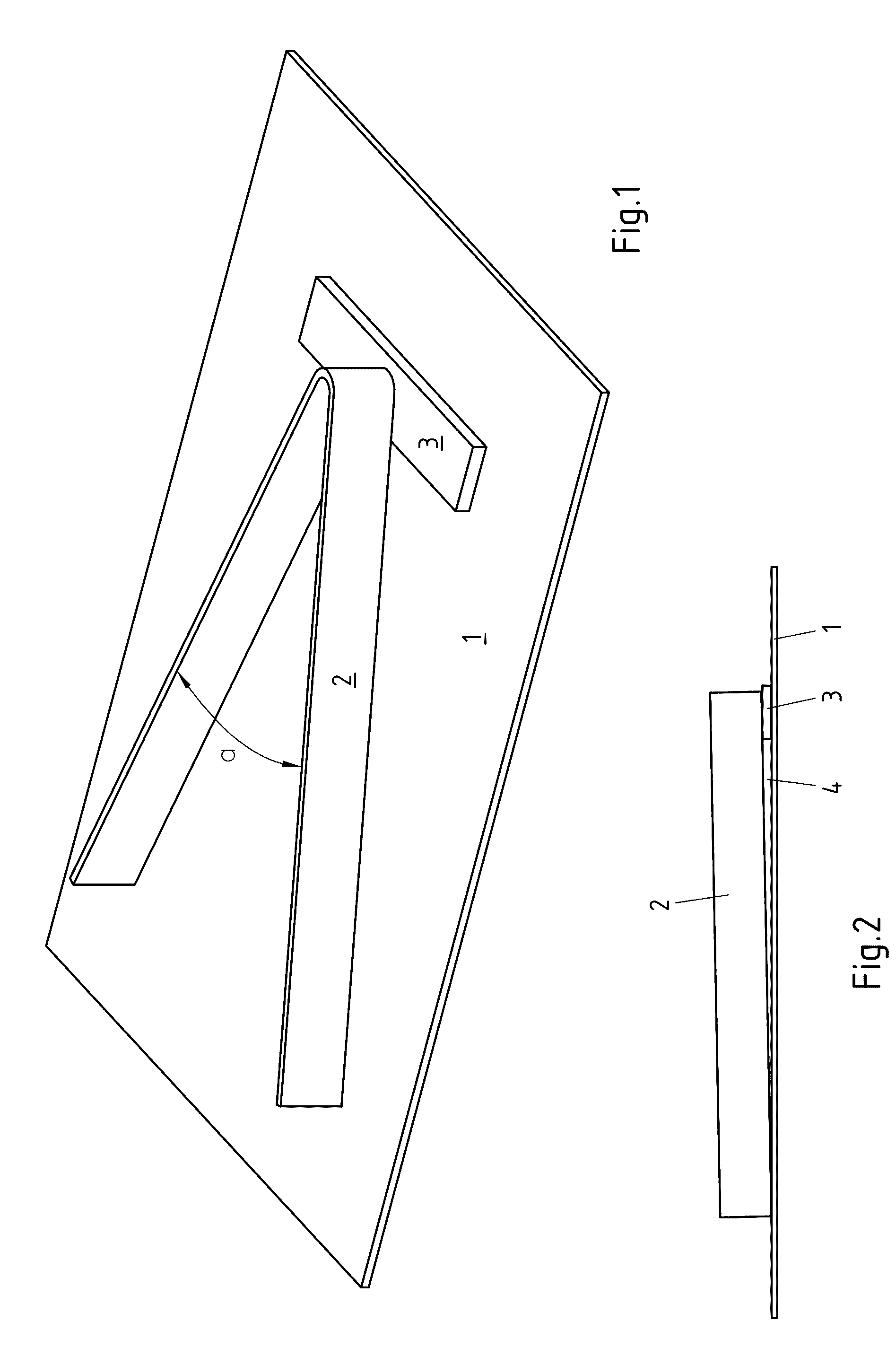

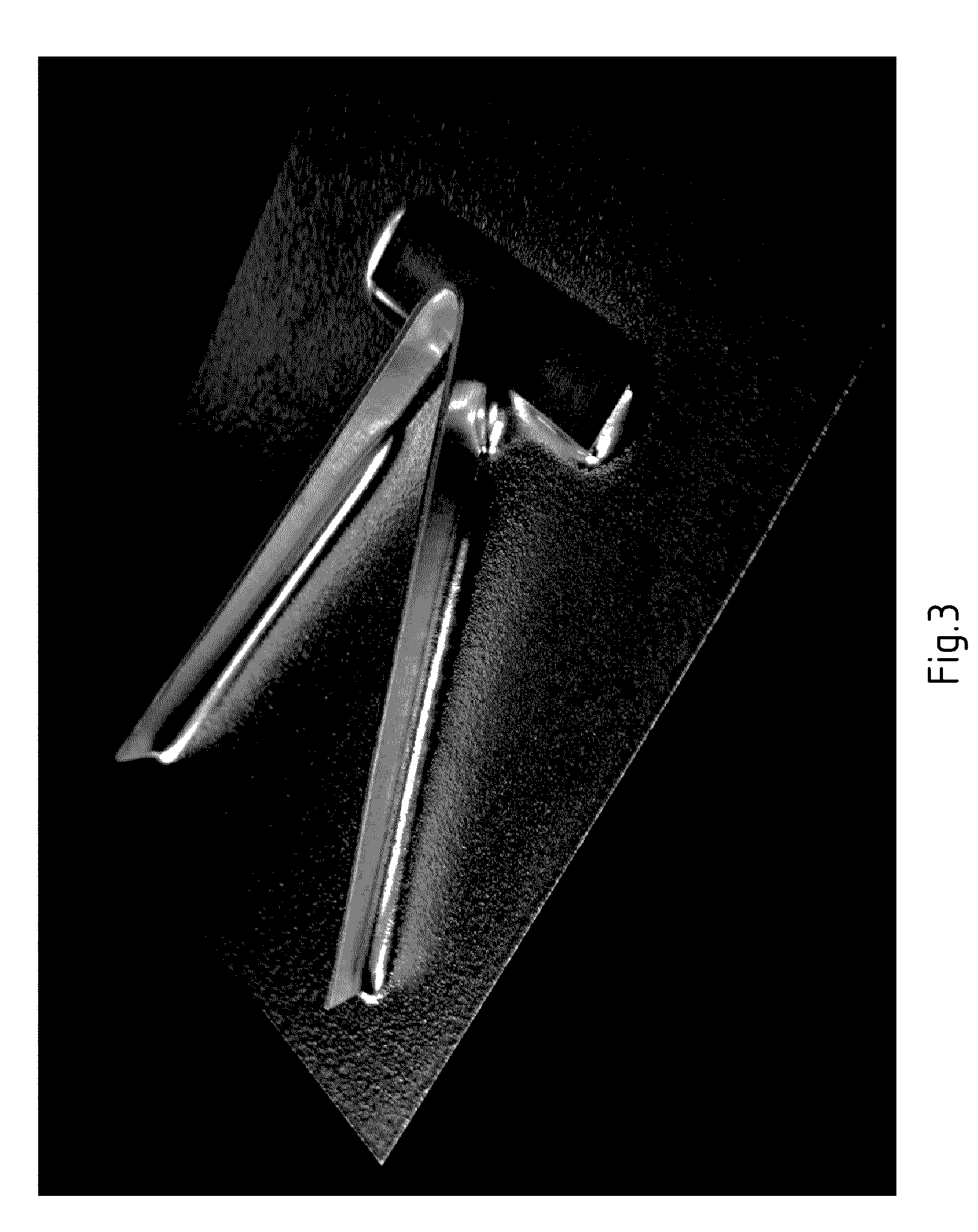

[0063]In order to investigate the advantages of the use according to the invention of the aluminium composite material, a large number of experiments were carried out with a specific brazing experimental arrangement, as illustrated in perspective view in FIG. 1. In principle the brazing experimental arrangement consists of a total of three parts, a sheet 1, an angle sheet 2 and a supporting sheet 3 for the angle sheet 2. The angle sheet 2 lies with its closed end 2a on the supporting sheet 3 arranged on the sheet 1. Both arm ends 2b on the other hand lie on the sheet 1, so that, as illustrated in the side view in FIG. 2, a varying gap is formed starting from the supporting point of the arm ends 2b of the angle sheet 3 up to the supporting point of the closed end 2a on the supporting sheet 3. The brazing joint clearance or gap 4 becomes increasingly larger starting from the angle ends 2b up to the closed end 2a of the angle sheet. Owing to the increasing brazing joint clearance 4 it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com