Reverse cold extrusion mold for car rear transversal stabilizer bar casing tube

A stabilizer bar and reverse extrusion technology, applied in the field of metal material plastic forming molds, can solve problems such as inconvenient installation and adjustment of punches, complex structure of extrusion punches, and difficulty in processing and manufacturing, and achieve a wide range of process applications and excellent structure Simple, long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

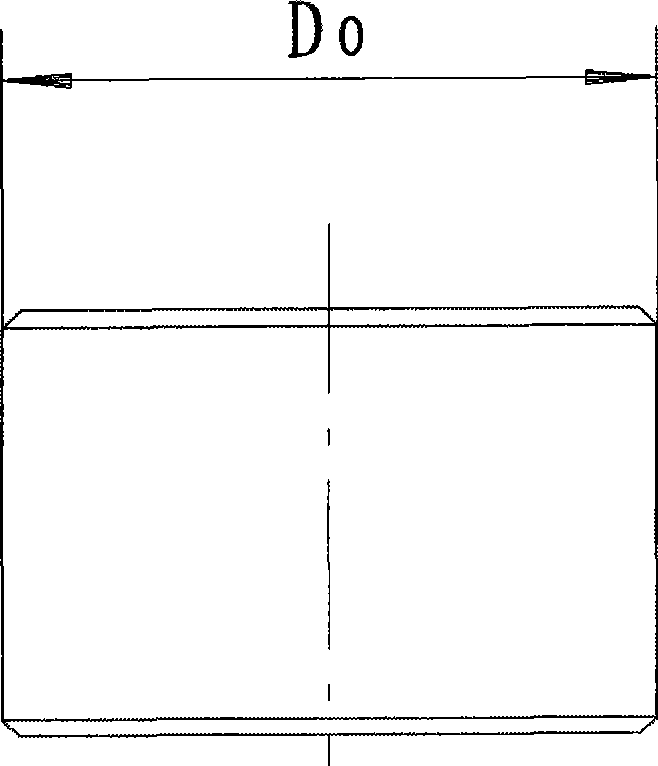

[0025] figure 1 It is a schematic diagram of the blank of the rear stabilizer bar casing to be processed. The blank is cylindrical with a diameter of D 0 is 36mm.

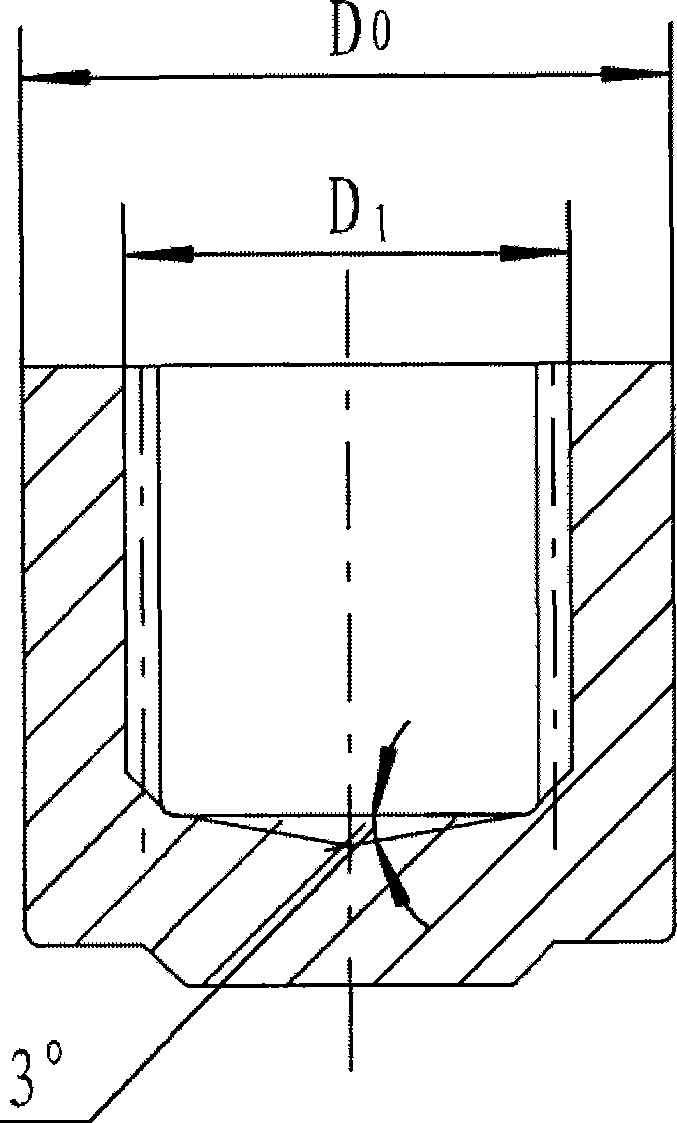

[0026] Figure 2A , Figure 2B It is a schematic diagram of the extrusion part of the rear stabilizer bar sleeve formed by reverse extrusion of the present invention, and the inner diameter of the spline tooth bottom is D 1 is 26.2mm, the tooth length is 26.5mm, the modulus is 0.78, the number of teeth is 32 (right piece) and 30 (left piece), the pressure angle is 45°, the bottom is 3°cone angle, and the casing outer diameter is D 0 is 36±0.5mm, and the height is 36.5mm.

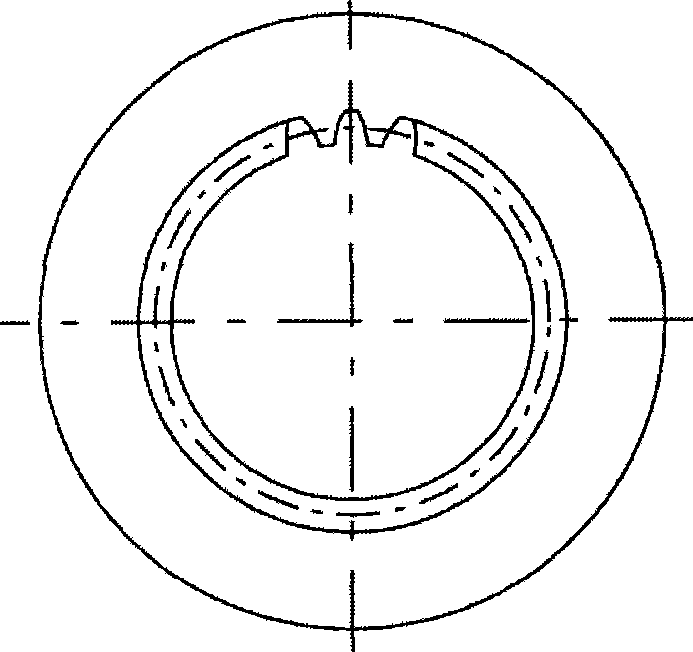

[0027] Such as image 3 As shown, the die of the present invention includes a reverse extrusion die, an ejector, a reverse extrusion punch and a guide;

[0028] The reverse extrusion die is composed of a lower template 1, a lower die base 4, a lower backing plate 5, a die base 7, a die 8, a die bottom ring 21, a prestressed ring 9, an outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com