Oil-containing sludge resourceful treatment technology

A treatment process and resource utilization technology, applied in the sludge dehydration of oily sludge and crude oil recovery treatment process, can solve the problems of high cost, complicated process operation and unfavorable practical application of three-phase decanter centrifuges, and achieve improved crushing efficiency. Milky effect, excellent biodegradability, good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

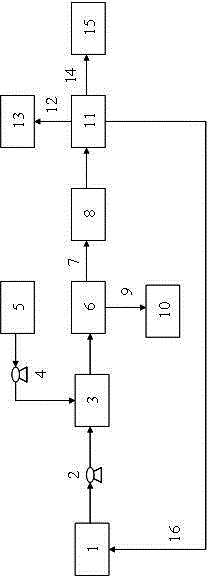

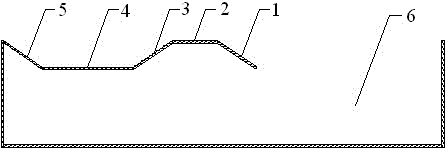

Method used

Image

Examples

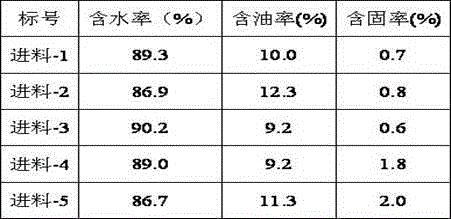

Embodiment 1

[0034] The concrete embodiment of the present invention is illustrated by taking the oil sludge at the bottom of a refinery as an example. The oily sludge content analysis of the feed is shown in Table 1. The weight percentages of the components of the demulsifier are: sodium lauryl alcohol ether carboxylate 15wt%, sodium silicate 20wt%, sodium chloride 2wt%, sodium hydroxide 1wt% , Water 62wt%, demulsifier dosage is 3% of sludge weight. The mixing time of the demulsifier in the sludge mixing tank is 30 minutes, and the temperature of the mixing tank is controlled at about 60°C. Using the process of the present invention to treat oily sludge, the water content of the discharged mud cake is reduced to 51.1%-54.9%, and the oil content is 16.9%-22.3%, as shown in Table 2. Through material balance calculation, the volume of sludge after dehydration treatment is reduced by at least 10 times, which greatly reduces the difficulty of subsequent sludge treatment. The contents of chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com