Ring Polishing Disc Correction Method and Pitch Formula for Ultra-Low Scattering Mirror of Laser Gyroscope

A technology of laser gyroscope and mirror, applied in the field of high-precision laser gyroscope, to achieve the effect of solving processing efficiency

Inactive Publication Date: 2014-04-23

FLIGHT AUTOMATIC CONTROL RES INST

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

method and asphalt formula

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0080]

Embodiment 2

[0097]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

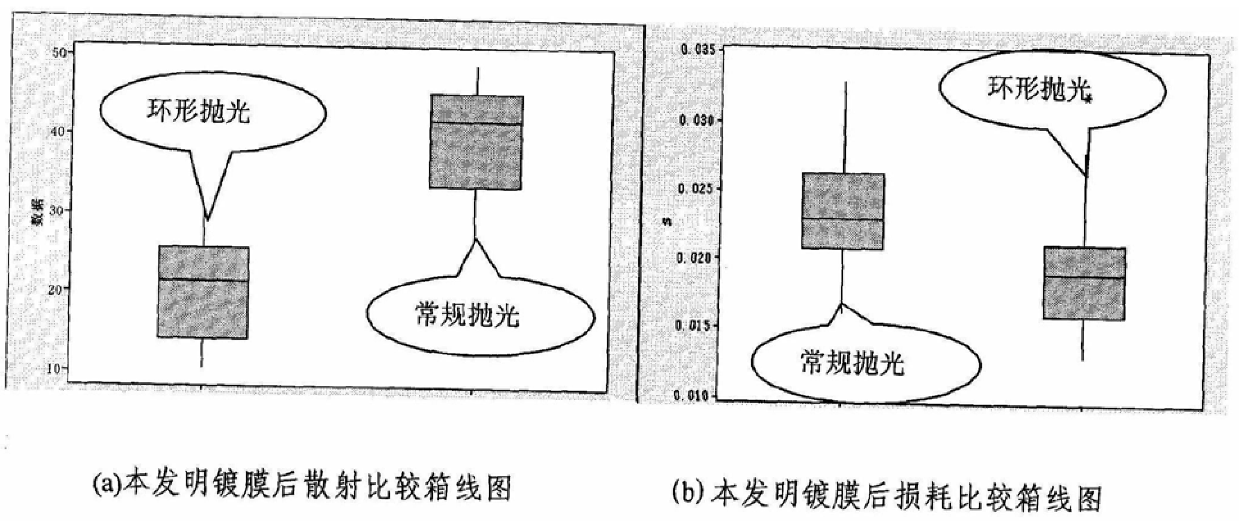

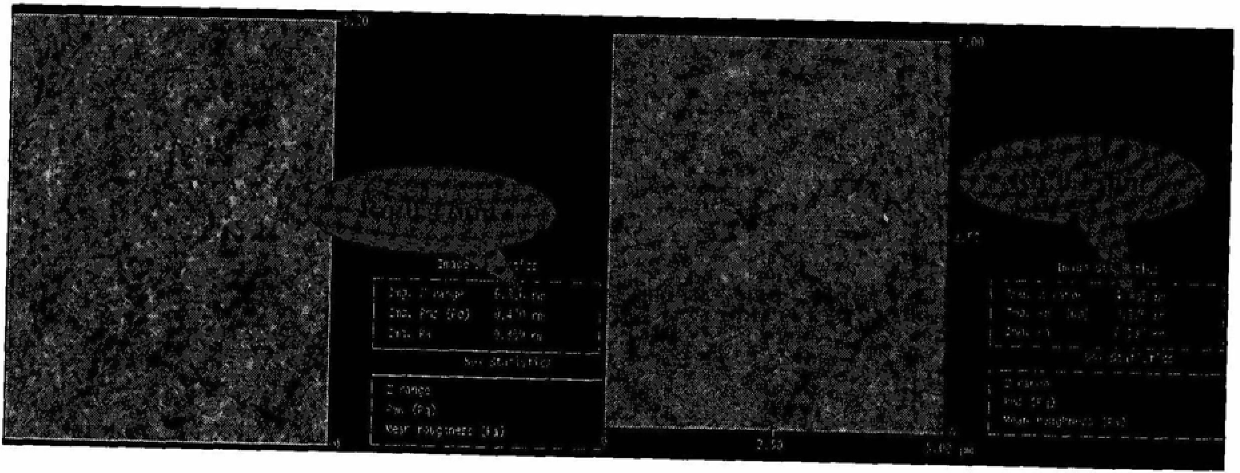

The invention relates to a method for correcting an annular polishing disc and its asphalt formula, in particular to a method for correcting an annular polishing disc suitable for a high-precision laser gyroscope with extremely low scattering mirrors and its asphalt formula. The present invention adopts mechanical turning tool to turn asphalt surface, groove shape determination, correction parameter control, etc., to form a set of methods for correcting polishing discs; adopt the asphalt with grades 82# and 73# produced by Global Optics in the United States, and the required asphalt ratio Be 82#: 73#=1 / 3~3 / 5. Apply the polishing disc made by the asphalt formula of the present invention and apply it in the technological process of annular polishing in combination with the ring polishing disc correction method, the Rq of the processed parts is as follows; N=0.2; ΔN=0.1; the surface defect is 0 grade; Very low scattering substrate coating requirements are met. It has played a positive role in improving the accuracy, reliability and stability of high-precision laser gyroscopes.

Description

Ring Polishing Disc Correction Method and Pitch Formula for Ultra-Low Scattering Mirror of Laser Gyroscope technical field The present invention relates to a kind of correction method of annular polishing disc and pitch formula thereof, especially about high-precision laser top Modification method and asphalt formulation of annular polishing disk for spiral extremely low scattering mirror. Background technique Laser gyroscope very low scattering reflector is as the core component of laser gyroscope, plays an important role to the precision of laser gyroscope system critical use. The reflectivity of the mirror surface determines the accuracy of the laser gyro system, the scattering is reduced, and the reflection rate also increased. The size of the scattering is one of the most important factors affecting the accuracy of the laser gyroscope. The smaller the scattering, the better the accuracy of the gyro system. The higher the accuracy. The factors affecting scatte...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B24B13/01B24D3/00C08L95/00

Inventor 宋晓莉李顺增邓小兵

Owner FLIGHT AUTOMATIC CONTROL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com