Processing device used for vacuum coating

A processing device and vacuum coating technology, which are applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, can solve the problem of impure components of the coating layer of the substrate, affecting the stability of the performance of the substrate, and affecting the substrate performance. Quality life and other issues, to achieve the effect of improving quality and normal life, reducing impact, and connecting firmly and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe in detail the technical content and structural features of the processing device for vacuum coating of the present invention, further description will be made below in conjunction with the embodiments and accompanying drawings.

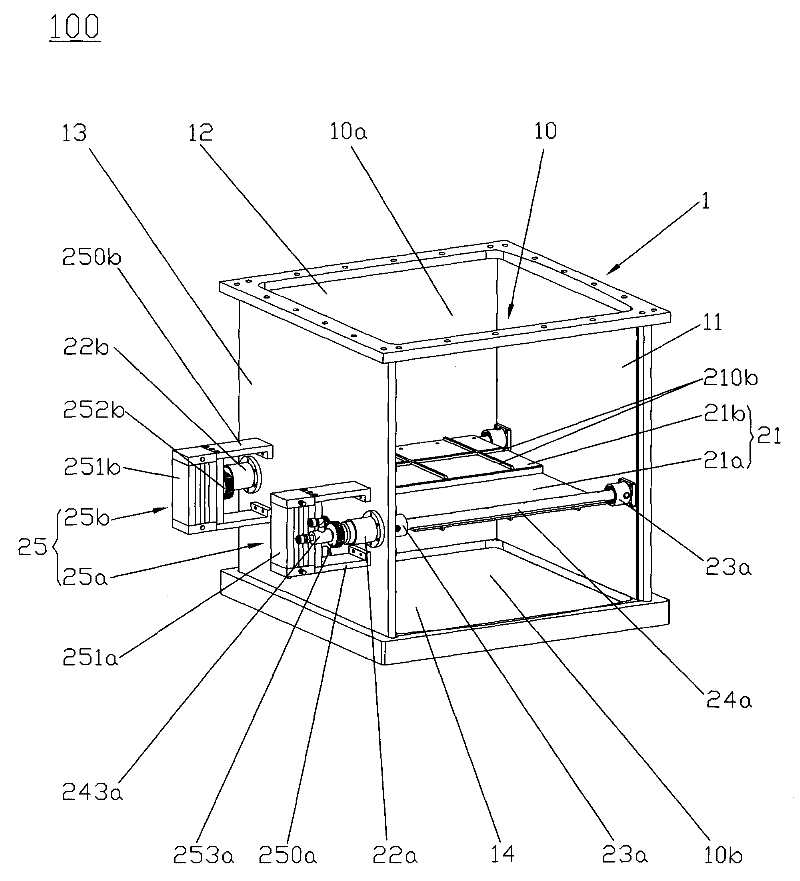

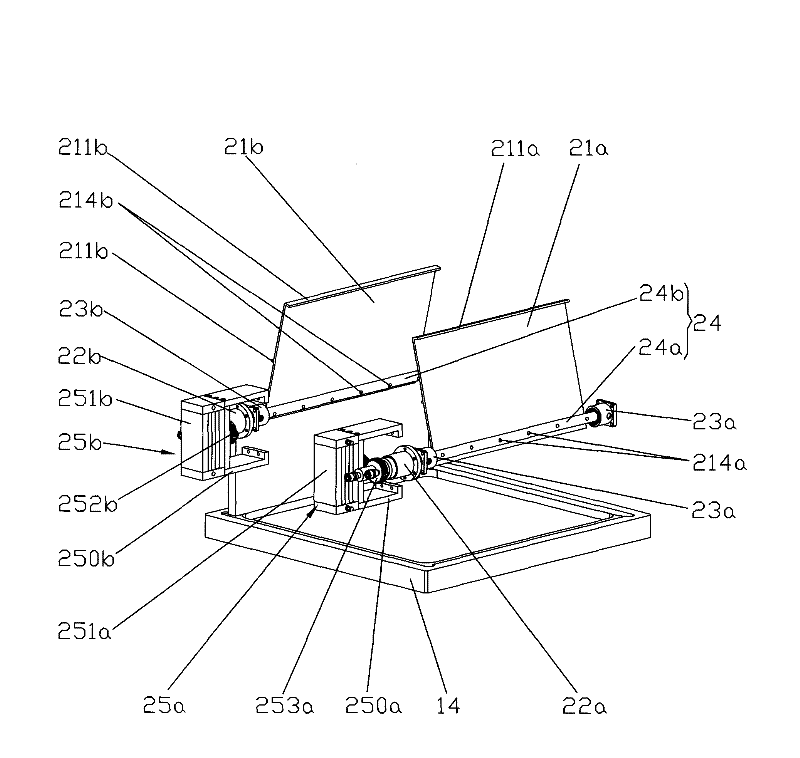

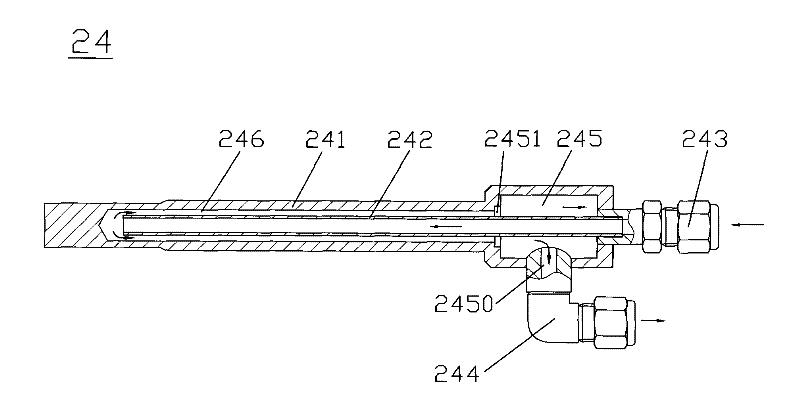

[0023] First, see figure 1 and figure 2 . exist figure 1 and figure 2Among them, the processing device 100 for vacuum coating of the present invention is used in the vacuum coating process of organic light emitting diodes, which includes a cabinet 1, a processing board and an evaporation source (not shown in the figure). This cabinet body 1 is formed by the sealing connection of left side plate 13, right side plate 11, front door plate (not shown in the figure), rear plate 12, bottom plate 14 and top plate (not shown in the figure), and above-mentioned left side plate 13. The right side panel 11 , the front door panel, the rear panel 12 , the bottom panel 14 and the top panel form the sealed chamber 10 of the cabinet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com