Oily sludge advanced treatment technology

A kind of advanced treatment and process technology, applied in water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, water/sewage multi-stage treatment, etc. Complex, unfavorable practical application and other problems, to achieve the effect of good demulsification effect, wide application range and easy industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

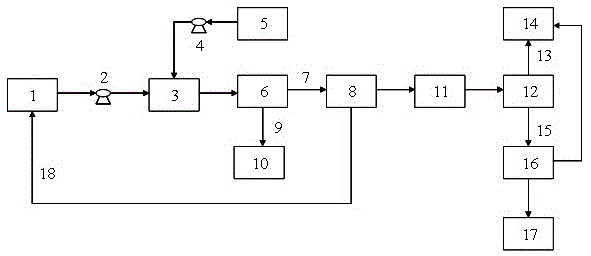

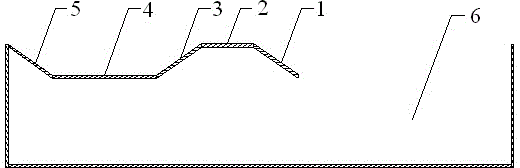

Method used

Image

Examples

Embodiment 1

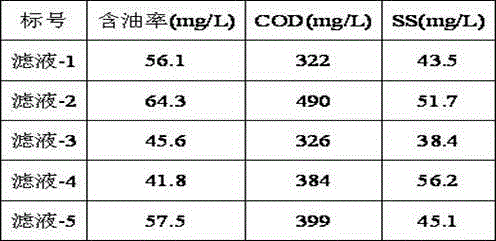

[0034] The concrete embodiment of the present invention is illustrated by taking the oil sludge at the bottom of a refinery as an example. The analysis of the oily sludge content of the feed is shown in Table 1. The weight percentage of each component of the demulsifier is: disodium fatty alcohol polyoxyethylene ether sulfosuccinate monoester (R=C 18 ) 18wt%, potassium lauryl ether phosphate (chemical formula: RO(CH 2 CH 2 O) n -PO(OK) 2 , R=C 14 , n=9) 15wt%, styrene 1wt%, oxalic acid 0.6wt%, water 65.4wt%. The dosage of demulsifier is 3% of the sludge weight. The mixing time of the demulsifier in the sludge mixing tank is 30 minutes, and the temperature of the mixing tank is controlled at about 65°C. Using the process of the present invention to treat oily sludge, the water content of the discharged mud cake is reduced to 50.3%-53.8%, and the oil content is 17.0%-21.4%, as shown in Table 2. Through material balance calculation, the volume of sludge after dehydration t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com