Electrolytic machining tool used for flexible part

A technology for processing tools and flexible parts, which is applied in the field of electrolytic processing tools, can solve problems such as difficult quality and precision assurance, mechanical cutting force, and poor mechanical properties of parts, so as to optimize the processing process, improve the flow field, and prevent leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

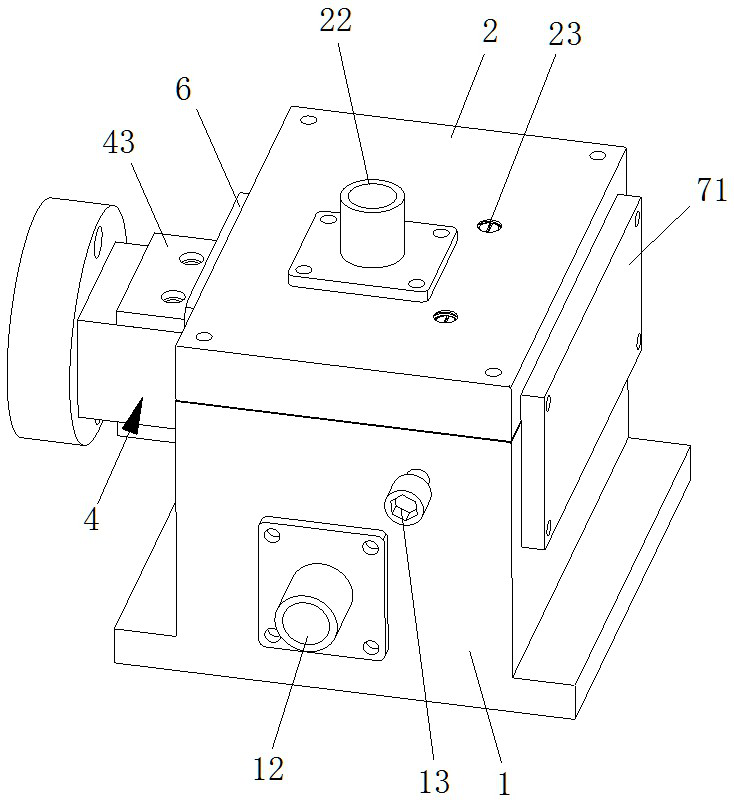

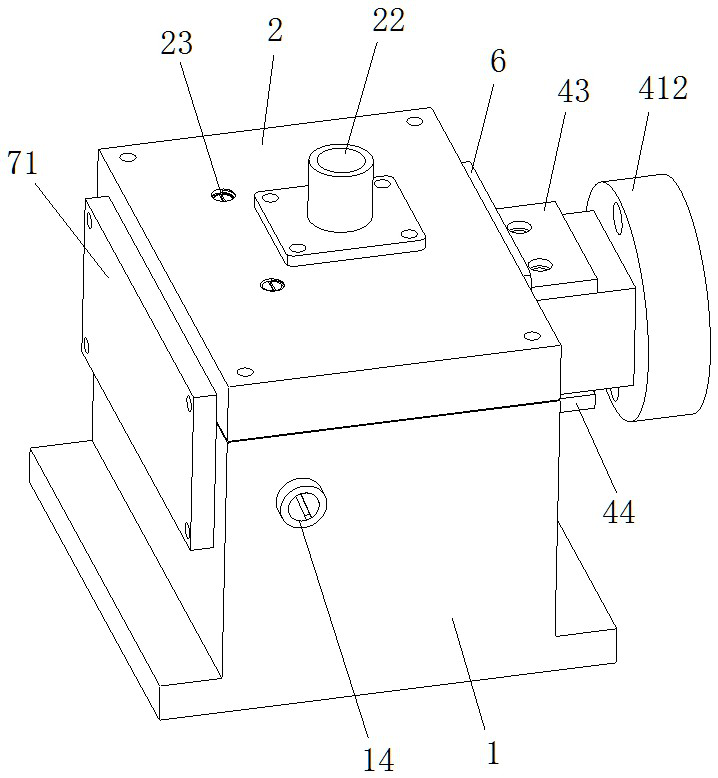

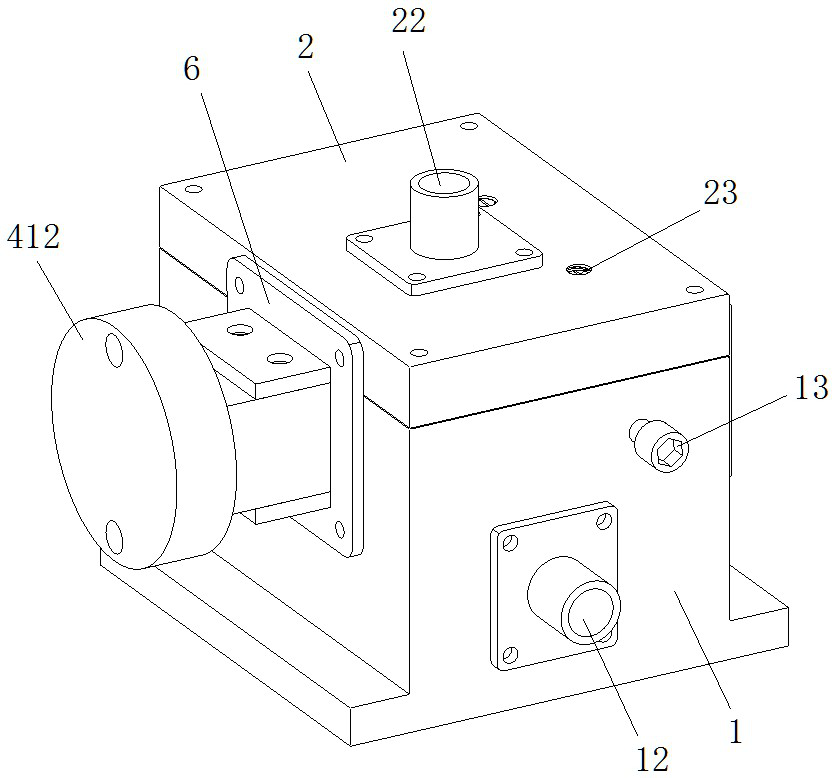

[0044] The present invention will be further described below in conjunction with accompanying drawing:

[0045] Such as Figure 1 to Figure 4 , Figure 7 ~ Figure 9 The shown electrolytic machining tool for flexible parts includes a base 1 and a cover plate 2 matched with the base 1, the base 1 and the cover plate 2 are equivalent to a clamp body, and the base 1 and the cover plate 2 are connected by hexagon socket bolts connection, the base 1 is provided with a tank body 3 that runs through the left and right sides of the base 1, the tank body 3 includes a first tank body 31 that matches the electrolytic machining cathode 4 and a second tank body 32 that matches the component 5 to be processed, The component 5 to be processed is limited by the positioning and clamping device to move and rotate in the second groove body 32, the first groove body 31 is perpendicular to the groove length direction of the second groove body 32 and the first groove body 31 is connected to the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com