High-speed ultrasonic vibration assistant air drill

A technology of ultrasonic vibration and air drilling, which is applied in the direction of vibrating fluid, portable drilling rig, drilling/drilling equipment, etc., which can solve the problem of unsuitable drilling and processing of deep and small holes, restricting the wide application of air drilling, and low speed of air drilling And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This example is a high-speed ultrasonic vibration assisted air drill.

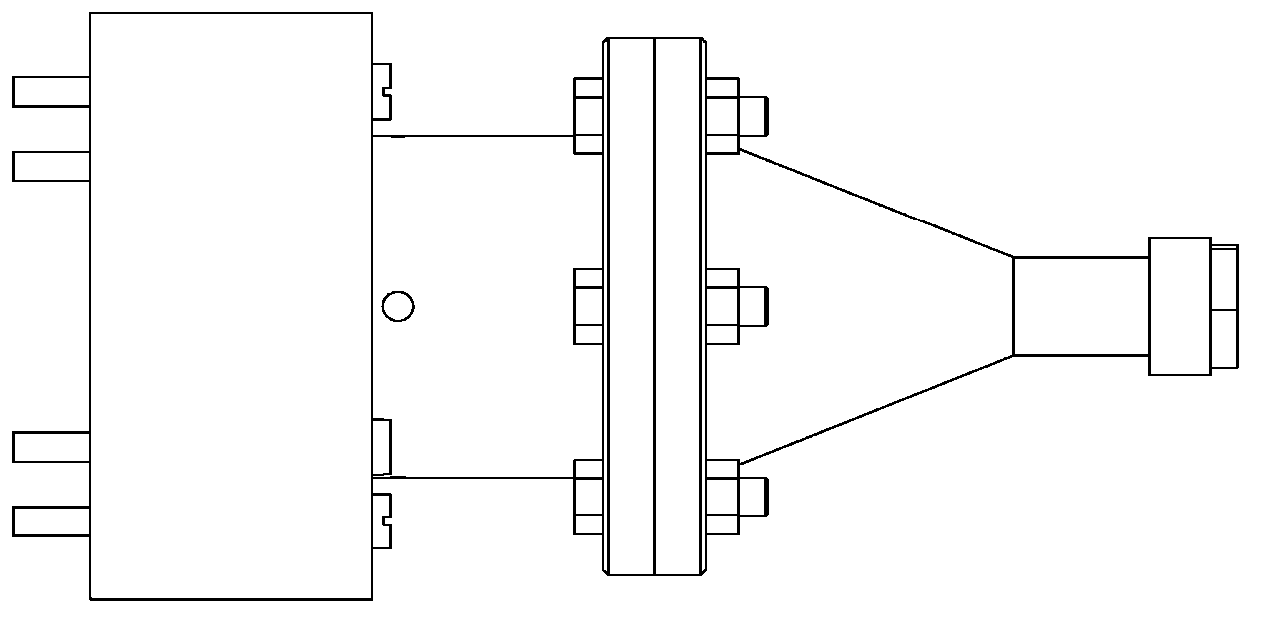

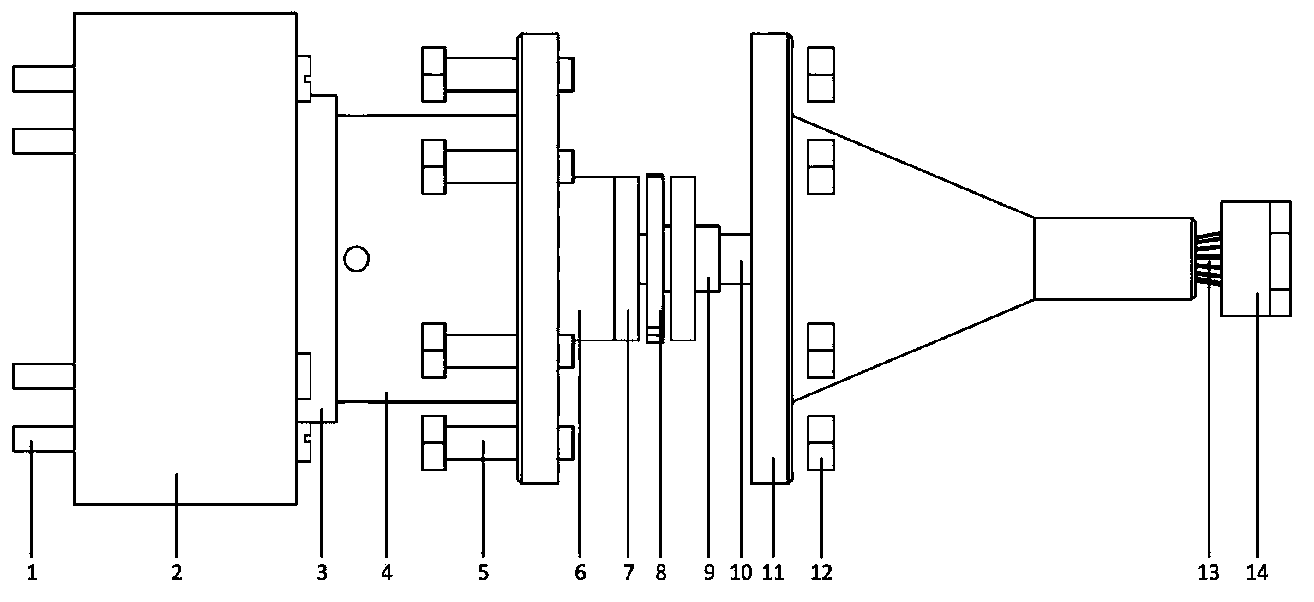

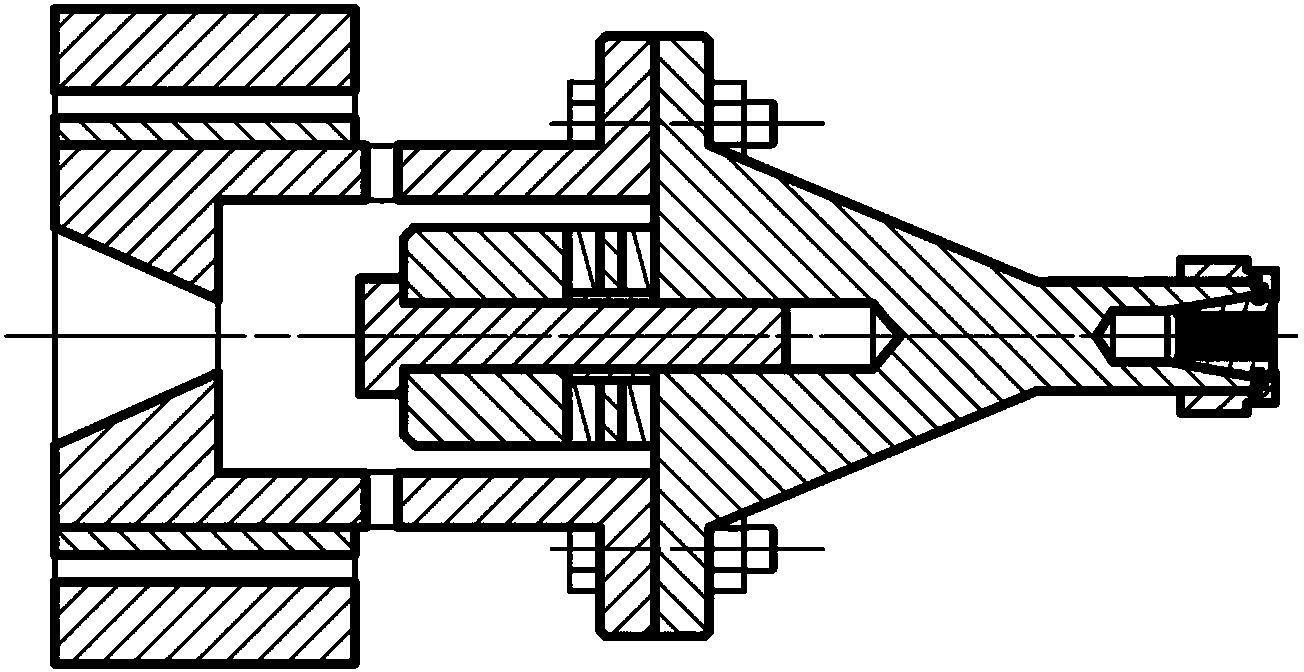

[0025] refer to figure 1 , figure 2 , image 3 , the high-speed ultrasonic vibration assisted air drill of the present invention is composed of an ultrasonic generator, an ultrasonic wireless power transmission mechanism, a connecting mechanism, an ultrasonic transducer mechanism, an ultrasonic luffing mechanism and a drill bit clamping mechanism. Tight bolt connection; the drill bit clamping mechanism and the ultrasonic horning mechanism are connected through the thread at the front end of the horn; the ultrasonic transducer mechanism and the connecting mechanism are connected through the end face flange; The primary side of the device, the electric energy is transmitted to the secondary side of the power transmission device through electromagnetic induction, and the lead wire from the secondary side is transmitted to the ultrasonic transducer inside the connecting mechanism through the small ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com