Transmission platform for semiconductor wafer processing

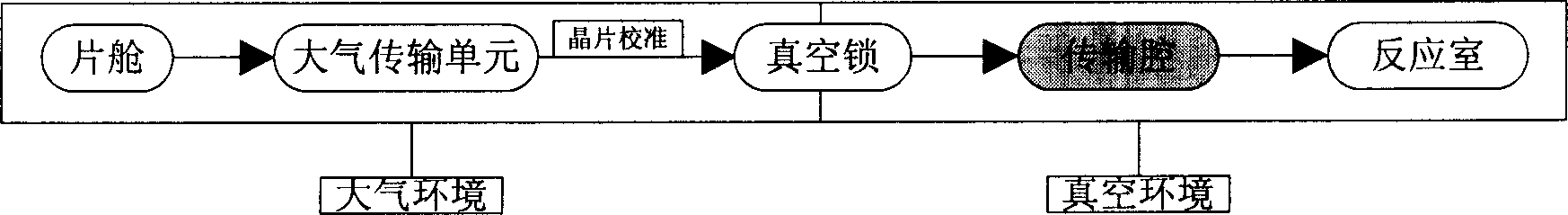

A technology of wafer processing and transmission platform, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of limited number of wafers, difficult to improve production efficiency, etc., to achieve good compatibility, improve output rate, reduce the effect of exchange frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Those of ordinary skill in the relevant technical field can also make various changes and modifications without departing from the spirit and scope of the present invention. Therefore All equivalent technical solutions also belong to the category of the present invention, and the scope of patent protection of the present invention should be defined by each claim.

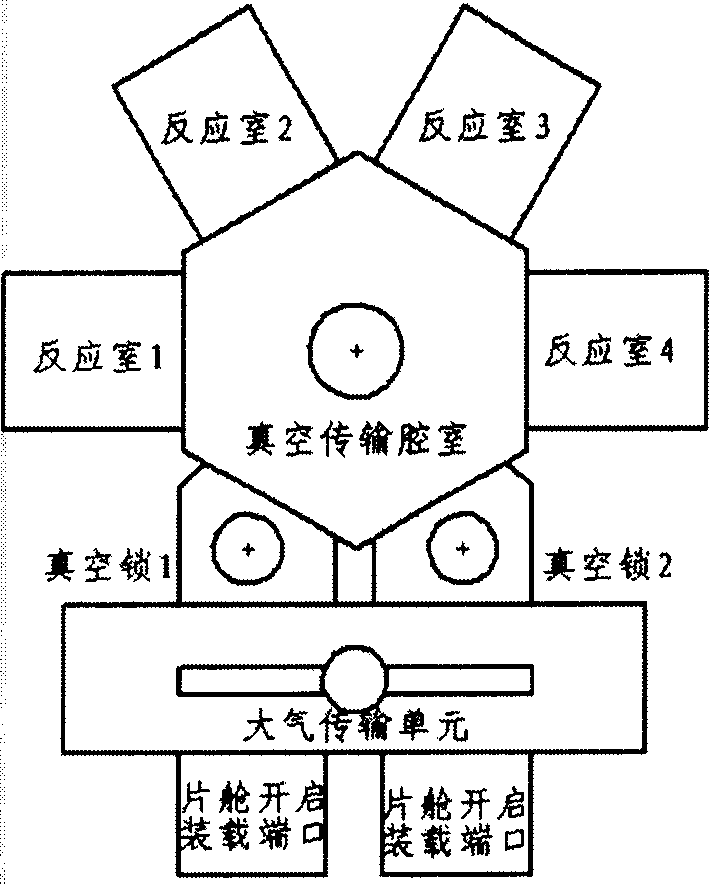

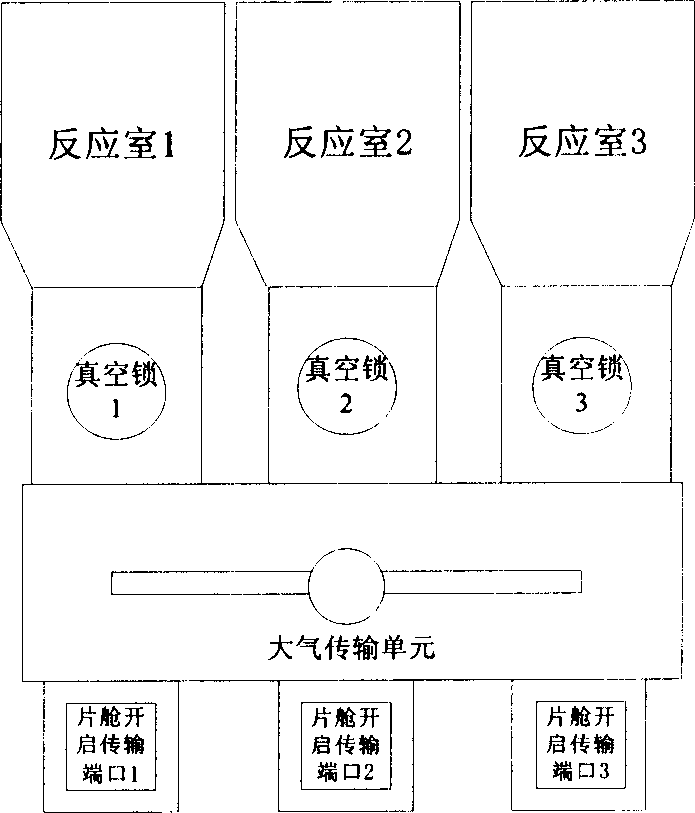

[0026] Such as Figure 5 As shown, a transmission platform for semiconductor wafer processing includes two wafer cabins with open loading ports, first to sixth reaction chambers, and an axisymmetric hexagonal structure vacuum transmission chamber, which adopts an axisymmetric non-regular hexagonal structure. Arrange two vacuum manipulators R1, R2 on the polygonal axis in the vacuum transfer chamber, and arrange two wafer temporary storage areas P1, P2 symmetrically perpendicul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com