Processing method for inclined planes and inclined plane hole systems of V-shaped machine engine body

A processing method and body technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of V-type diesel engine body processing difficulties and other problems, and achieve the effects of wide processing application, cost saving and processing efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

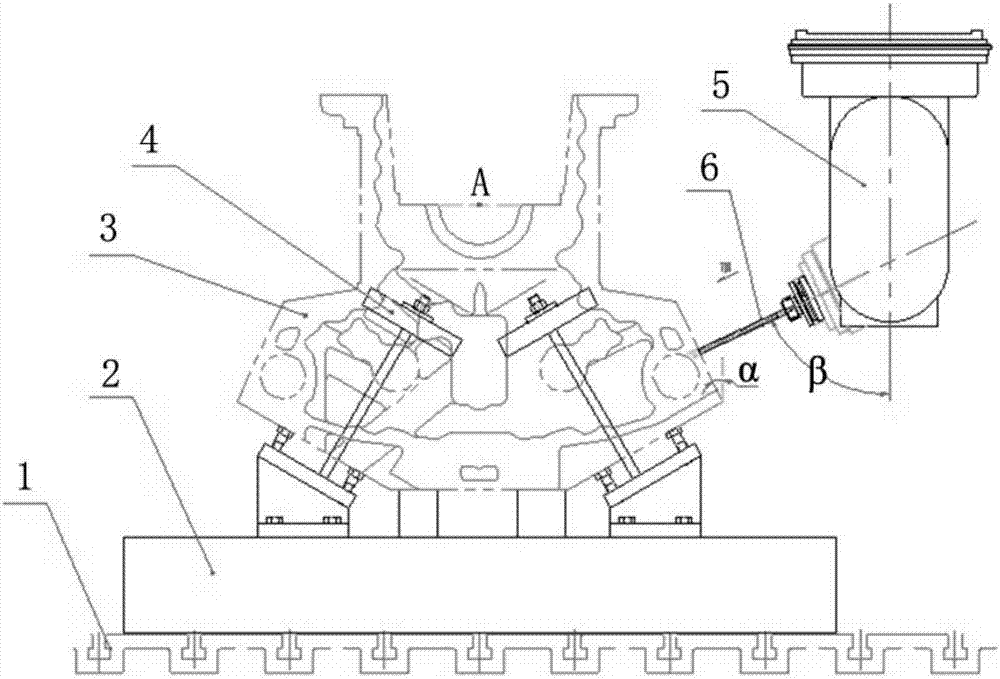

[0023] refer to figure 1 , a V-type machine body inclined plane and inclined plane hole system processing method, the specific steps are as follows:

[0024] (a) Install the V-shaped machine body 3 on the V-shaped machine body boring and milling tooling 2, place the two as a whole on the workbench of the CNC gantry boring and milling machine 1, align the inclined plane along the X-axis direction of the CNC gantry boring and milling machine and press Tighten, make the slope of the V-type machine body 3 form an angle α with the XZ plane of the CNC gantry boring and milling machine, and press the body with the pressure plate 4;

[0025] (b) Adjust the angle β of the main shaft of the universal angle head 5 to zero degrees, and measure the coordinate zero point A of the body 3 through the edge finder;

[0026] (c) Adjust the included angle β of the main shaft of the universal angle head 5, so that the universal angle head 5 and the axis of the CNC gantry boring and milling machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com