Metal cold hot cut circular saw blade sawtooth grinding method

A circular saw blade and sawtooth technology, applied in the field of metal processing, can solve the problems of affecting the sawing effect of the saw blade, easy to wear or chip, and the cutting life is not as good as the new one, so as to improve the sawing effect, reduce the processing cost, and eliminate the sawtooth. The effect of easy wear or chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

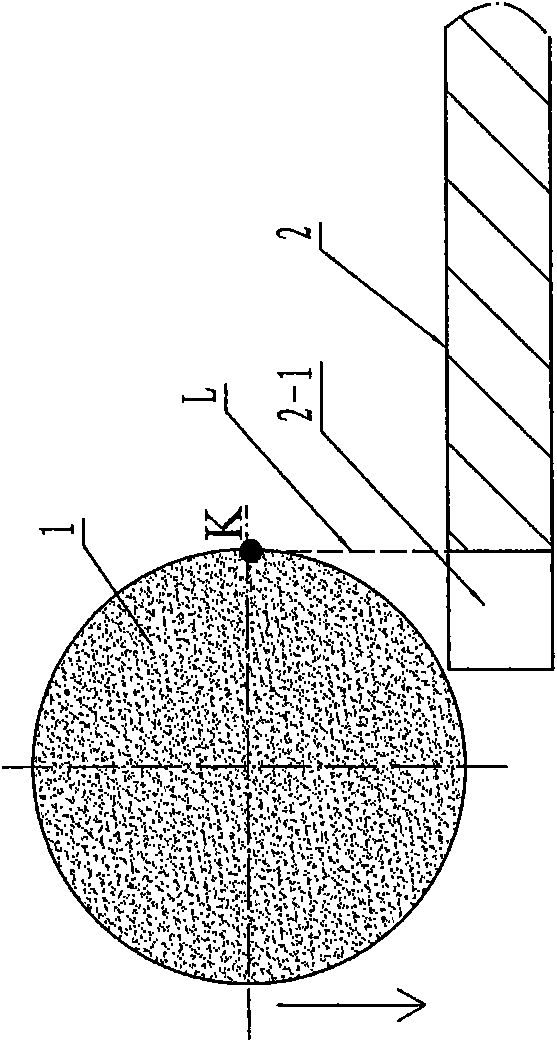

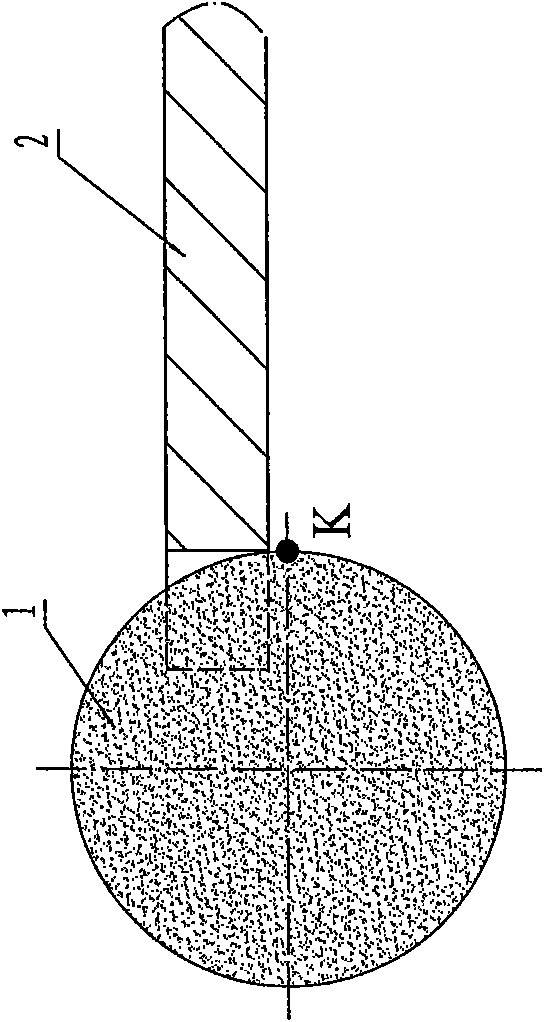

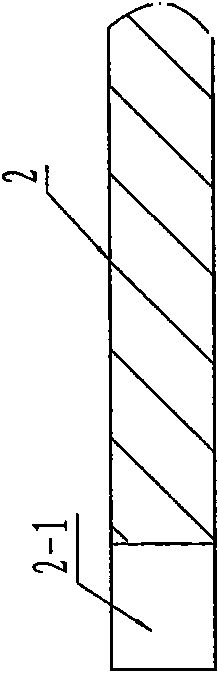

[0021] The method of the present invention can be used for grinding metal cold and hot cutting circular saw blades of various tooth types, and the process is as follows: a. The saw blade to be ground is installed on the grinding machine, and the installed saw blade can rotate freely without hindrance. b. see Figure 4 , select the grinding wheel 1 that matches the sawtooth 2-1 profile of the saw blade 2 to be ground, and install the grinding wheel. c. The grinding wheel rotates to grind each saw tooth of the saw blade to be ground one by one. When grinding each saw tooth, the feeding direction of the grinding wheel is along the axial direction of the saw blade to be ground; see figure 1 , the position of the grinding wheel 1 relative to the sawtooth 2-1 before the axial feed should meet the following requirements: the K point with the closest distance from the outer circumference of the grinding wheel to the sawtooth is located on the extension line L of the tooth root of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com