Erosion deposition test device and test method with multi-characteristic pipe sections, multi-angle positions, and controllable particle concentration

A particle concentration and testing device technology, applied in the direction of analyzing materials, instruments, etc., can solve the problem of not being able to realistically simulate the erosion and deposition of particle concentration, and achieve the effect of ensuring the accuracy of element replacement testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

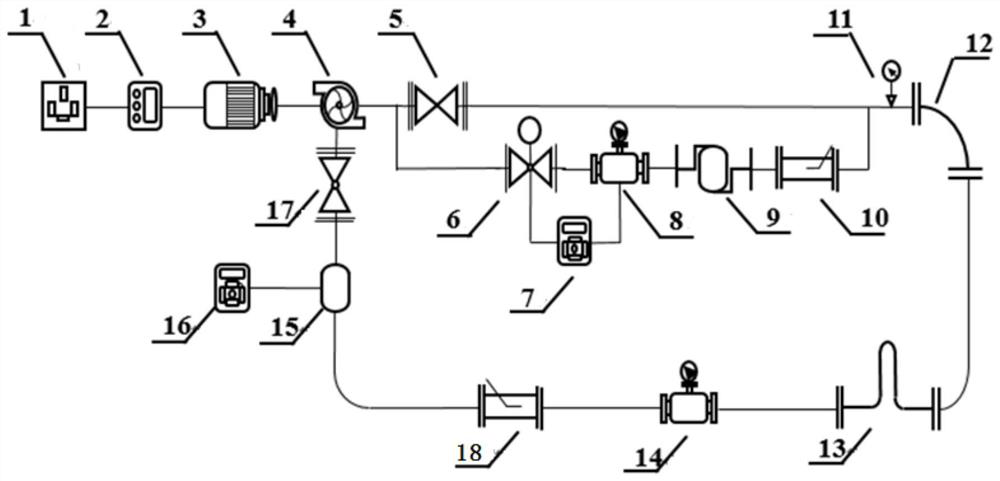

[0040] Example 1: see Figure 1 to Figure 4 , the erosion deposition testing device with multi-characteristic pipe sections, multi-angle positions and controllable particle concentration in this embodiment includes a power unit, a main pipeline of a circulation pipeline and a desalination bed branch.

[0041] Wherein, the power unit includes a frequency converter 2, a three-phase motor 3 and a centrifugal pump 4; the input end of the frequency converter 2 is connected to the three-phase power supply 1, and the output end is connected to the three-phase motor 3, which is changed by changing the frequency of the output power supply The speed of the three-phase motor 3 is controlled by means of a method, so as to achieve the purpose of controlling the flow rate of the pipeline medium; the three-phase motor 3 is connected to the frequency converter 2 in front and the centrifugal pump 4 in the rear to provide power for the centrifugal pump 4; the water inlet of the centrifugal pump ...

Embodiment 2

[0050] Example 2: see Figure 1 to Figure 4 , the multi-featured pipe section, multi-angle position, and controllable particle concentration erosion deposition test method of this embodiment, the method is based on the erosion deposition with multi-featured pipe section, multi-angle position, and controllable particle concentration described in Example 1 The test equipment is realized, including:

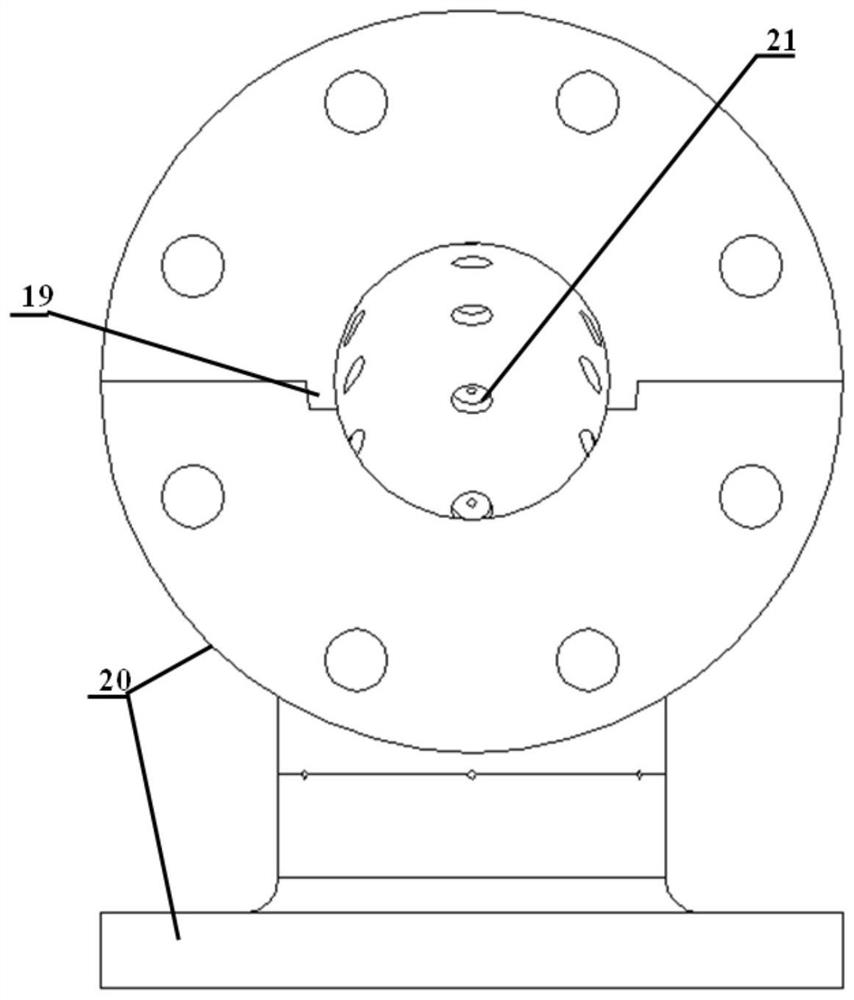

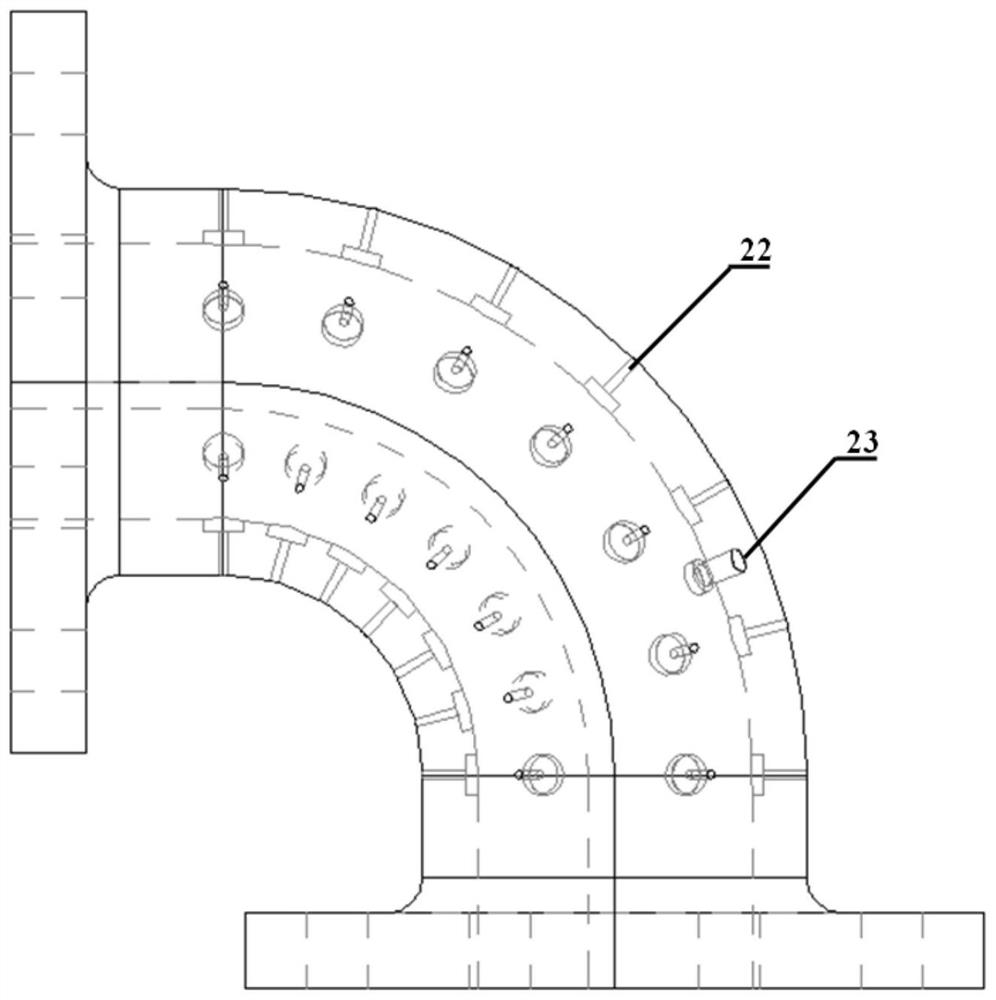

[0051] The first step: paste the test sample in the test piece installation hole 21 in the 90° test elbow 12 and the flexible test pipe section 13, install the wire in the wire through hole 22, connect the wire with the test sample, and connect the reference electrode hole and auxiliary A reference electrode and an auxiliary electrode are inserted into the electrode hole 23. During the test, the test sample is connected to the electrochemical workstation through wires respectively, and the reference electrode and the auxiliary electrode are connected to the electrochemical workstati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com