Bullet-proof plate with buffering isolation layer and manufacturing method thereof

A technology of isolation layer and bulletproof plate, applied in protective equipment, offensive equipment, armor plate structure and other directions, can solve the problems of long heat preservation and pressure holding time, low production efficiency, high surface density, and achieve less thickness specifications and improved production efficiency , the effect of low areal density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

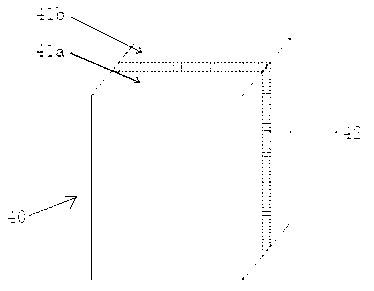

[0044] see figure 1 As shown, the bulletproof board 10 with a buffer isolation layer includes two layers of curved UHMWPE fiber bulletproof substrates 11a, 11b and a buffer isolation layer 12 disposed between the two layers of bulletproof substrates 11a, 11b.

[0045] see figure 1 , prepare the bulletproof board 10 containing the buffer isolation layer, the preparation method is: use ultra-high molecular weight polyethylene fiber as material, and prepare the bulletproof substrate by pressing and cutting. The two layers of bulletproof substrates 11a, 11b are stacked, and a certain space is left between the two layers of bulletproof substrates 11a, 11b and fixed. The medium of the buffer isolation layer 12 between the two bulletproof substrates 11a, 11b is air. The bulletproof board 10 with a buffer isolation layer is formed by stacking two layers of bulletproof substrates 11a and 11b, with a buffer isolation layer 12 between the two layers of bulletproof substrates 11a and 11...

Embodiment 2

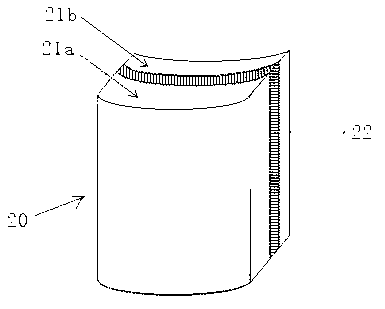

[0049] see figure 2 As shown, the bulletproof board 20 with a buffer isolation layer includes two layers of curved UHMWPE fiber bulletproof substrates 21a, 21b and a buffer isolation layer 22 disposed between the two layers of bulletproof substrates 21a, 21b.

[0050] see figure 2, prepare the bulletproof board 20 containing the buffer isolation layer, the preparation method is: use ultra-high molecular weight polyethylene fiber as material, prepare the bulletproof substrate by pressing and cutting, and cut the polyethylene foam material according to the designed size. The two layers of bulletproof substrates 21a, 21b are laminated with polyethylene foam. The medium of the buffer isolation layer 22 between the two bulletproof substrates 21a, 21b is polyethylene foamed cotton. The bulletproof board 20 with a buffer isolation layer is formed by stacking two layers of bulletproof substrates 21a and 21b, and a buffer isolation layer 22 is formed between the two layers of bulle...

Embodiment 3

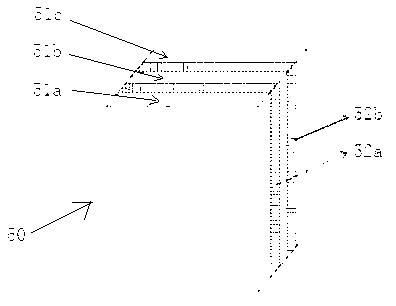

[0054] see image 3 As shown, the bulletproof board 30 containing the buffer isolation layer includes a curved plate-shaped ceramic bulletproof substrate 31a, two layers of curved plate-shaped ultra-high molecular weight polyethylene fiber bulletproof substrates 31b, 31c, and two layers of curved plate-shaped The buffer isolation layer 32 between the ultra-high molecular weight polyethylene fiber bulletproof substrates 31b, 31c.

[0055] see image 3 , to prepare the bulletproof board 30 containing the buffer isolation layer, the preparation method is: using bulletproof ceramics as the material, and preparing the ceramic bulletproof substrate 31a by cutting. Using ultra-high molecular weight polyethylene fibers as materials, the ultra-high molecular weight polyethylene fiber bulletproof substrates 31b and 31c are prepared by pressing and cutting. Two layers of ultra-high molecular weight polyethylene fiber bulletproof substrates 31b, 31c are stacked, and a certain space is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com