Strong magnetic variation gradient magnetic separator of inner permanent magnetic cylinder

A gradient magnetic separation and inner cylinder technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of low operating safety factor, no fine-tuning function of adjusting the magnetic gap distance, and affecting the separation effect, etc., to achieve Improve the effect of sorting index and grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

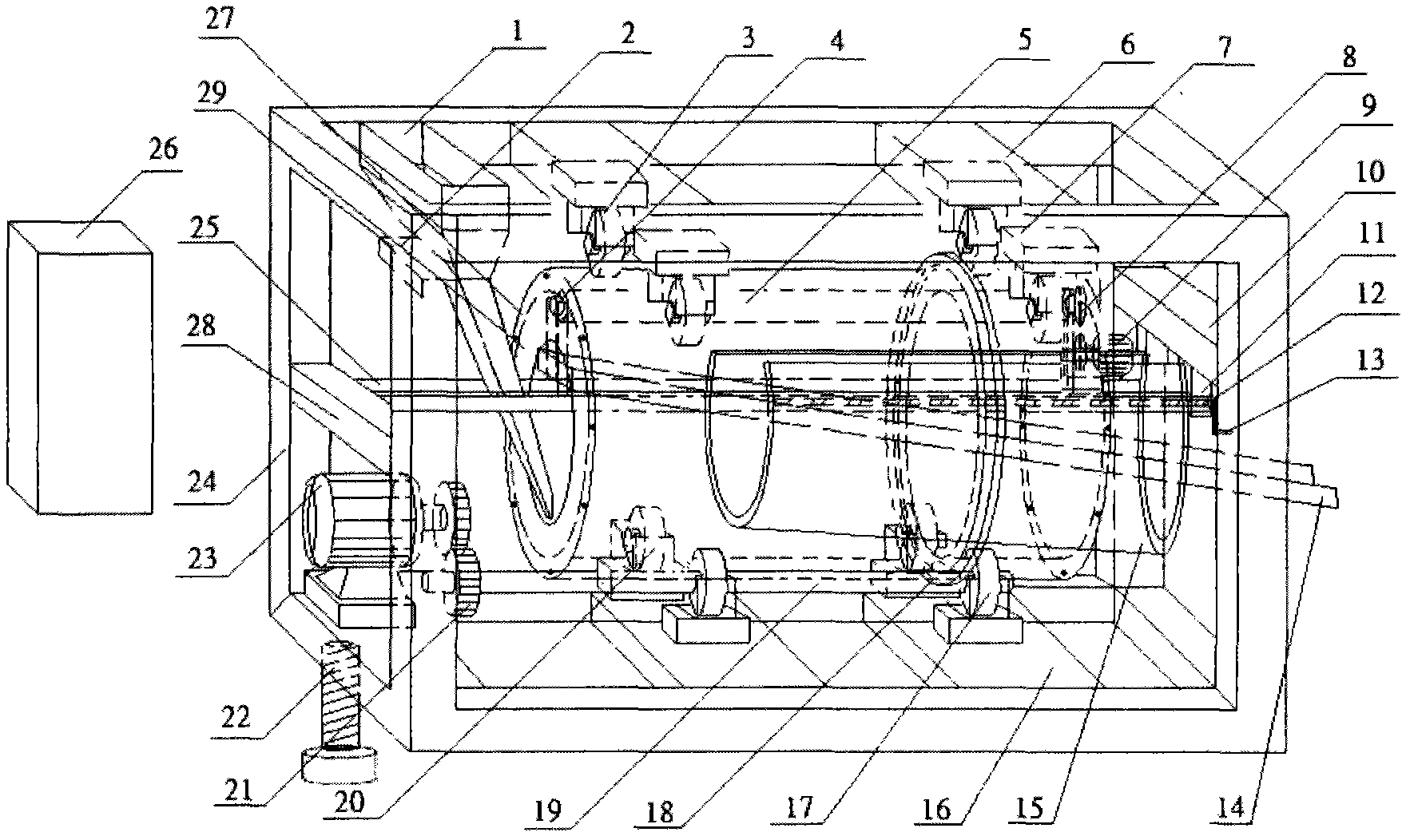

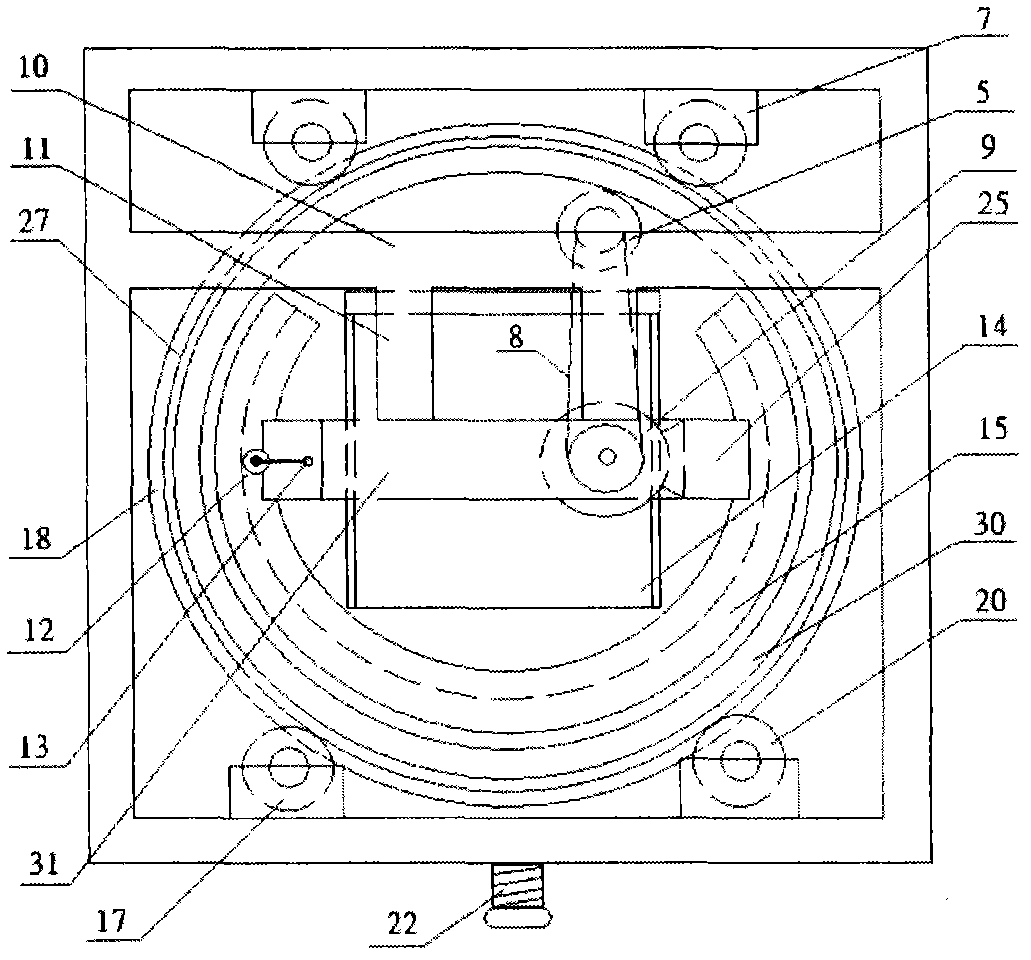

[0020] The following is a further detailed description of the permanent magnet inner cylinder strong magnetic variable gradient magnetic separator of the present invention in conjunction with the accompanying drawings:

[0021] see Attachment.

[0022] The present invention solves its technical problem. The specific implementation method is: the variable gradient magnetic separator in the permanent magnet inner cylinder is composed of a blanking box 1, a blanking amount control gate 2, a roller 3, a wool roller support 4, a blanking wool roller 5, and an upper bearing Beam 6, roller base 7, top roller belt pulley 8, top roller motor 9, right beam 10, inner bracket suspension rod 11, exciter moving screw 12, screw rotation handle 13, concentrate discharge chute 14, exciter 15 , Lower load-bearing beam 16, driving roller 17, flange 18, transmission connecting rod 19, passive roller 20, connecting rod gear 21, inclination adjustment screw 22, power motor 23, frame 24, inner suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com