Flotation separation method for high-sulfur copper-zinc ore

A high-sulfur copper-zinc separation method technology, applied in flotation, solid separation, etc., can solve the problems of difficult to effectively suppress zinc minerals, waste of resources, sticky copper flotation foam, etc., to increase the mineralization effect and reduce mechanical Entrainment, solve the effect of foam stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

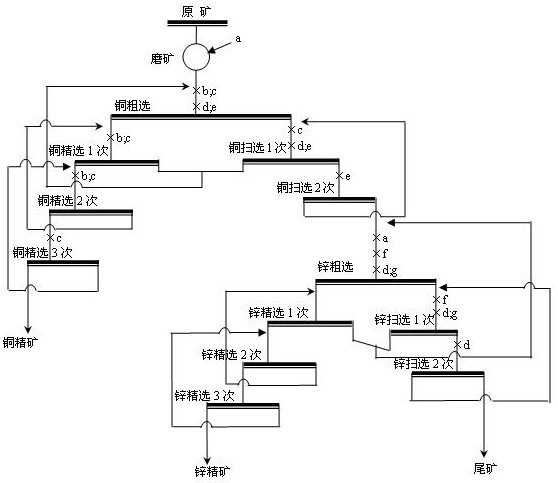

Method used

Image

Examples

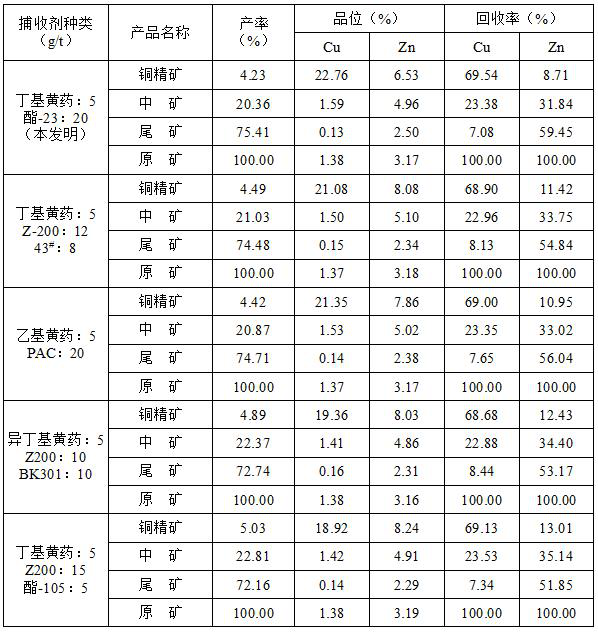

Embodiment 1

[0058] A copper-zinc ore in Xinjiang contains 1.38% Cu, 3.17% Zn, 17.13% S, and 32.14g / t silver. The pyrite content in the mineral content of the ore reaches more than 20%. The recyclable elements in the ore are Cu, Zn and Ag, which belong to high-sulfur associated gold-silver-copper-zinc sulfide ores. Metal minerals are mainly pyrite, followed by chalcopyrite, sphalerite, pyrrhotite and so on. Most of the metal minerals have a simple intercalation relationship, some chalcopyrite is finely grained and wrapped by pyrite, sphalerite and gangue; a small amount of pyrite is disseminated and dispersed in the gangue, and the cracks are filled with chalcopyrite, sphalerite and gangue. Sphalerite, etc.; the particle size distribution of pyrite, chalcopyrite, and sphalerite is basically uniform; the distribution of silver minerals is extremely uneven, and the particle size is generally less than 0.05mm, mainly occurring in chalcopyrite. The closed-circuit test results of Example 1 are...

Embodiment 2

[0079] A copper-zinc ore in Tibet contains 0.43% Cu, 2.33% Zn, 15.50% S, and 6.10g / t silver. The recyclable elements in the ore are Cu, Zn and Ag, which belong to high-sulfur copper-zinc sulfide ores. The metal minerals are mainly pyrite, pyrrhotite, chalcopyrite and sphalerite. Gangue minerals are mainly epidote, calcite, quartz, sericite, and plagioclase. The particle size distribution of chalcopyrite is uneven, and it belongs to fine-grained intercalation; sphalerite is the main zinc-bearing mineral, and it is closely related to pyrite, chalcopyrite, and pyrrhotite intercalation, and some of them are encased and contiguous. Difficult to monomer dissociation. The closed-circuit test results of Example 1 are shown in Table 2.

[0080]The specific process is as follows:

[0081] ⑴ Grinding:

[0082] The crushed high-sulfur copper-zinc raw ore and water are added to a ball mill for grinding at a mass ratio of 1:1, and lime (a) 800g / t is added according to the dry ore weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com