Beneficiation method for preparing ultra-pure iron ore concentrate by adopting magnetite concentrate

A technology for ultra-pure iron ore concentrate and beneficiation method, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problem that the iron grade of the concentrate is not ideal, it is not conducive to large-scale production, and the iron grade of the concentrate is not high. problems, to achieve the effect of simple system, strong applicability and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The TFe grade of a commercial-grade magnetite concentrate in China is 67.84%, and the main impurity is SiO 2 、Al 2 o 3 , CaO, and MgO contents are 5.20%, 0.36%, 0.028%, and 0.024%, respectively, and the contents of other impurity elements are relatively low.

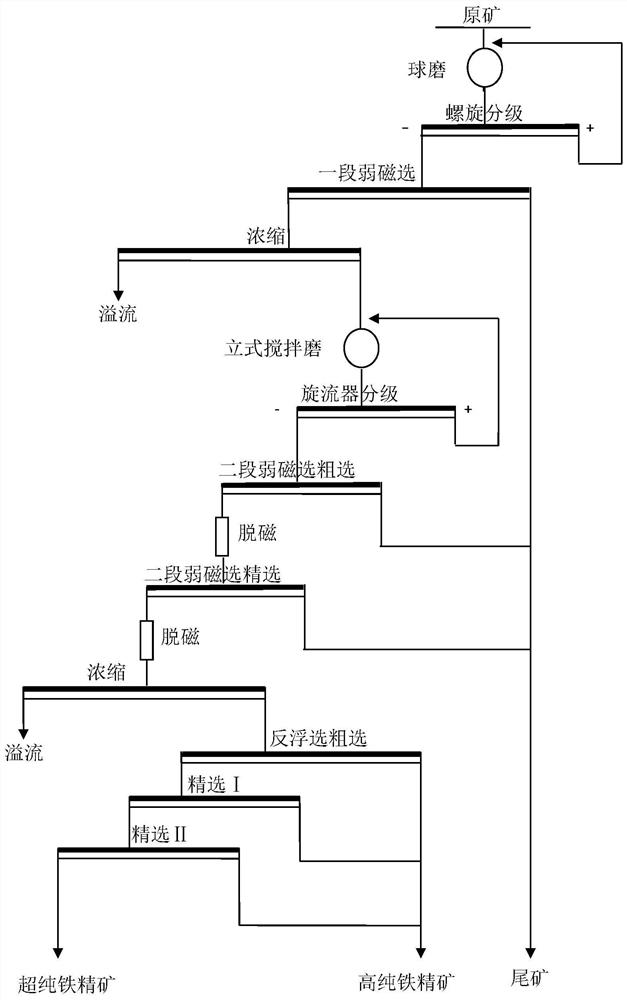

[0024] The ore sample is separated by stage grinding, stage magnetic separation-reverse flotation process. First, it undergoes a stage of ball milling, classification, and magnetic separation. The overflow particle size of the spiral classifier is -0.076mm, accounting for 90%. / m, the magnetic separation concentrate obtained is then adopted a grinding and grading system composed of a vertical stirring mill and a hydrocyclone. The overflow particle size of the cyclone is -0.038mm, accounting for 95%. One-time selection, roughing magnetic field intensity is 143.31kA / m, roughing concentrate is demagnetized and then refined, and the magnetic field strength of selection is 95.54kA / m, concentrated ore is concentrated ...

Embodiment 2

[0026] The TFe grade of a commercial grade magnetite concentrate in China is 66.72%, and the main impurity is SiO 2 、Al 2 o 3 , CaO, and MgO contents are 6.18%, 0.68%, 0.28%, and 0.22%, respectively, and the contents of other impurity elements are relatively low.

[0027]The ore sample is separated by stage grinding, stage magnetic separation-reverse flotation process. First, it undergoes a stage of ball milling, grading, and magnetic separation. / m, the magnetic separation concentrate obtained is then adopted a grinding and grading system composed of a vertical stirring mill and a hydrocyclone. The overflow particle size of the cyclone is -0.038mm, accounting for 90%. One-time selection, roughing magnetic field intensity is 159.24kA / m, roughing concentrate demagnetization treatment and then concentration, selection magnetic field strength is 127.39kA / m, selection concentrate is concentrated after demagnetization treatment, concentrated underflow to Into the reverse flotati...

Embodiment 3

[0029] The TFe grade of a commercial grade magnetite concentrate in China is 68.20%, and the main impurity is SiO 2 、Al 2 o 3 , CaO, and MgO contents are 4.53%, 0.27%, 0.024%, and 0.020%, respectively, and the contents of other impurity elements are relatively low.

[0030] The ore sample is separated by stage grinding, stage magnetic separation-reverse flotation process. First, it undergoes a stage of ball milling, grading, and magnetic separation. / m, the magnetic separation concentrate obtained is then adopted a grinding and grading system composed of a vertical stirring mill and a hydrocyclone. The overflow particle size of the cyclone is -0.038mm, accounting for 90%. One-time selection, roughing magnetic field intensity is 127.39kA / m, roughing concentrate is demagnetized and then refined, the magnetic field strength of selection is 95.54kA / m, concentrated concentrate is concentrated after demagnetization, and the concentrated underflow is given to Enter the reverse flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com