Classifying suspension roasting device for complex refractory iron ore

A technology for suspending roasting and iron ore, which is applied in the field of mineral processing to achieve optimal technical and economic indicators, improve reduction effect, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

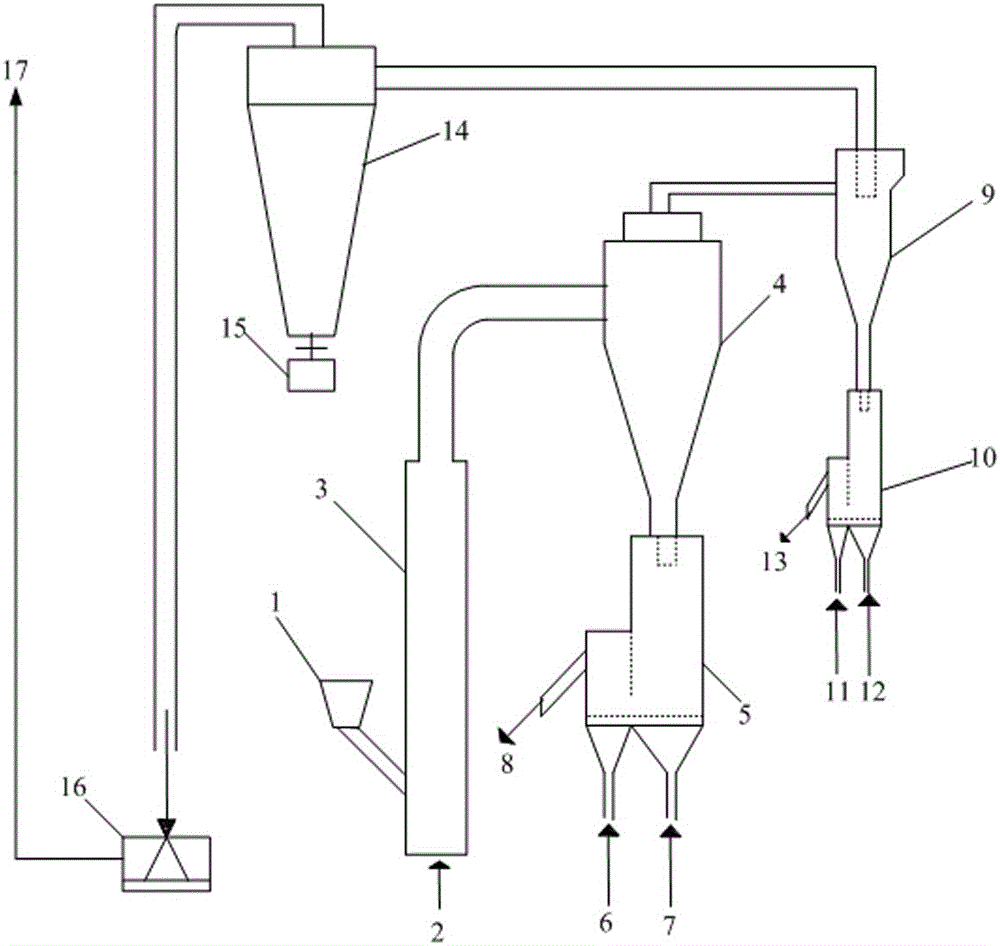

[0029] The structure of complex refractory iron ore classification suspension roasting device is as follows: figure 1 As shown, it includes a suspension preheating oxidizer, a two-stage cyclone classifier, a two-stage suspension reducer, a cyclone separator and a fan; the feed port of the suspension preheating The discharge port of the oxidizer is connected with the feed port of the primary cyclone classifier; the discharge port of the primary cyclone classifier is connected with the feed port of the secondary cyclone classifier, and the discharge port of the secondary cyclone classifier is connected with the cyclone The air inlet of the separator is connected, and the air outlet of the cyclone separator is connected with the inlet of the fan; the outlet of the first-stage cyclone classifier is inserted into the inlet of the first-stage suspension reducer, and the outlet of the second-stage cyclone classifier is inserted into the second In the feed inlet of the stage suspensio...

Embodiment 2

[0048] Device structure is the same as embodiment 1, and difference is:

[0049] (1) The suspension reducer is composed of a large cylinder and a small cylinder, the diameter-to-height ratio of the large cylinder is 1:3, and the diameter-to-height ratio of the small cylinder is 1:3;

[0050] (2) The ratio of the height of the communication port between the large cylinder and the small cylinder to the height of the small cylinder is 1:4, and the volume ratio is 1:0.4;

[0051] (3) The volume ratio of the primary suspension reducer to the secondary suspension reducer is 1:0.6;

[0052] (4) The volume ratio of the primary cyclone classifier and the secondary cyclone classifier is 1:0.6;

[0053] (5) The volume ratio of the suspension preheating oxidizer to the primary suspension reducer is 1:0.4;

[0054] Using method is the same as embodiment 1, and difference is:

[0055] (1) The temperature of the powder in the suspension preheating oxidizer is 800°C;

[0056] (2) The redu...

Embodiment 3

[0064] Device structure is the same as embodiment 1, and difference is:

[0065] (1) The suspension reducer is composed of a large cylinder and a small cylinder, the diameter-to-height ratio of the large cylinder is 1:4, and the diameter-to-height ratio of the small cylinder is 1:4;

[0066] (2) The ratio of the height of the communication port between the large cylinder and the small cylinder to the height of the small cylinder is 1:5, and the volume ratio is 1:0.5;

[0067] (3) The volume ratio of the primary suspension reducer to the secondary suspension reducer is 1:0.7;

[0068] (4) The volume ratio of the primary cyclone classifier and the secondary cyclone classifier is 1:0.7;

[0069] (5) The volume ratio of the suspension preheating oxidizer to the primary suspension reducer is 1:0.6;

[0070] Using method is the same as embodiment 1, and difference is:

[0071] (1) The temperature of the powder in the suspension preheating oxidizer is 1000°C;

[0072] (2) The red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| magnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com