Spiral concentrator

A technology of spiral concentrator and spiral groove, which is used in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of small processing capacity of single machine, weakened lateral circulation, and limited classification of particle size, etc., and achieves production cost. Low, long service life, strong wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

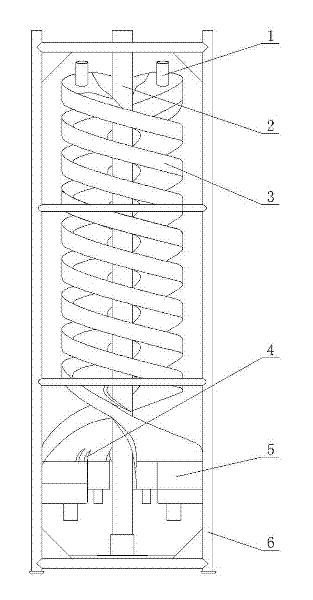

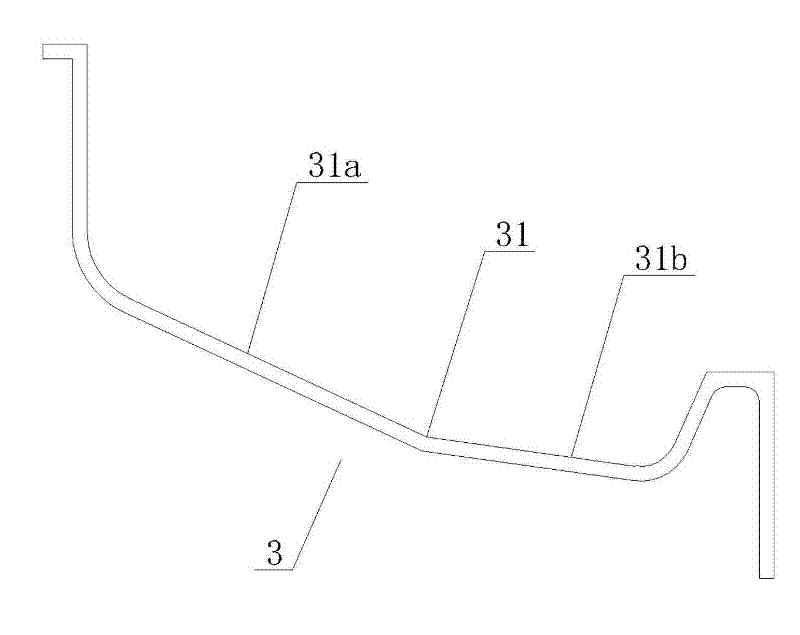

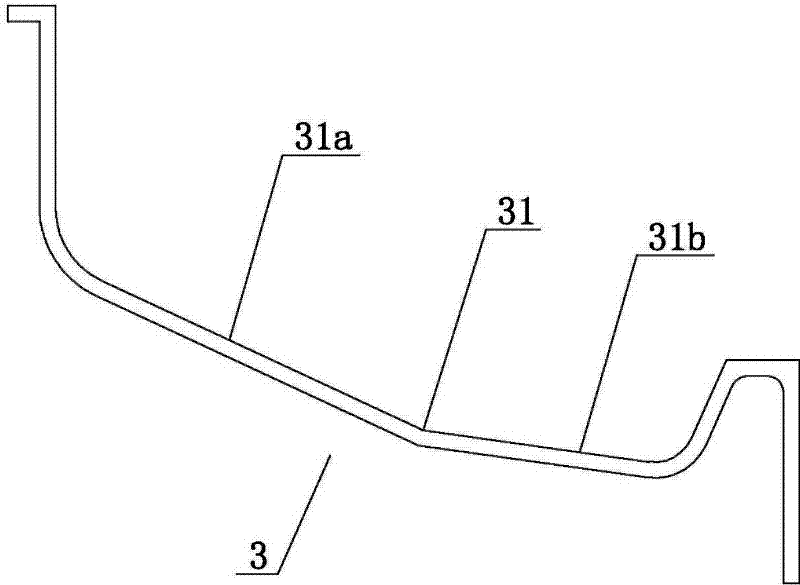

[0013] Such as Figure 1-Figure 2 As shown, the spiral concentrator of the present invention includes a frame 6, a center pipe 2 arranged on the frame 6, a spiral groove 3 fixedly connected to the center pipe 2, and a feed bucket arranged at the upper end of the spiral groove 3 1. The ore-connecting bucket 5 at the lower end, in which the center pipe 2 is located at the center of the frame 6 and its upper and lower ends are respectively connected and fixed with the upper and lower ends of the frame 6, while the spiral groove 3 adopts double ends, and the spiral groove 3. The cross section of the sorting surface 31 is composed of a straight line 31a near the outer edge and a straight line 31b near the inner edge, and the straight line 31a near the outer edge and the straight line 31b near the inner edge are respectively inclined from outside to inside. Through such arrangement, the sorting surface 31 of the spiral groove 3 is composed of two inclined planes with different later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com