An Improved Surface Structure of Yunnan Tin Shaker Coarse Sand Shaker

A technology of coarse sand and bed strips, which is applied in the field of bed surface structure of Yunnan tin shaker, to reduce the loss of cassiterite, improve the ability of elimination, and slow down the effect of disorder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

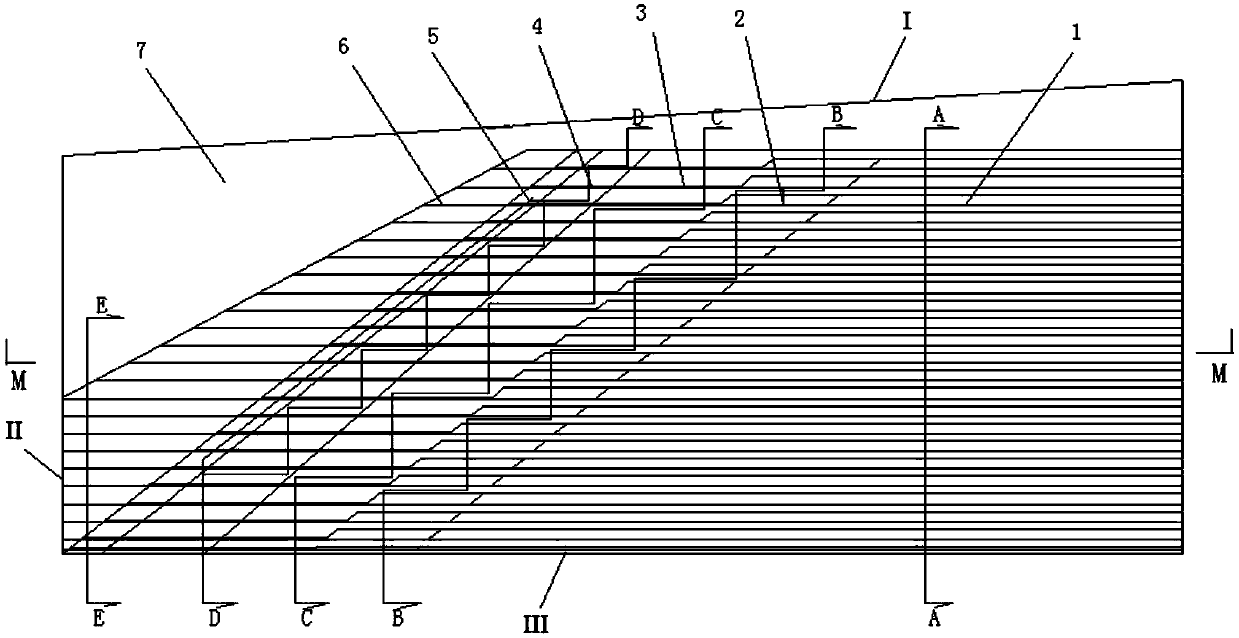

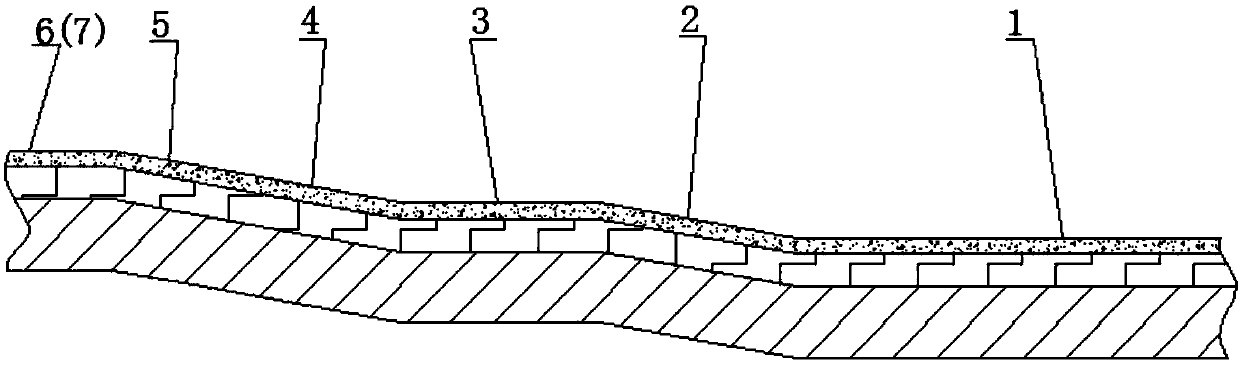

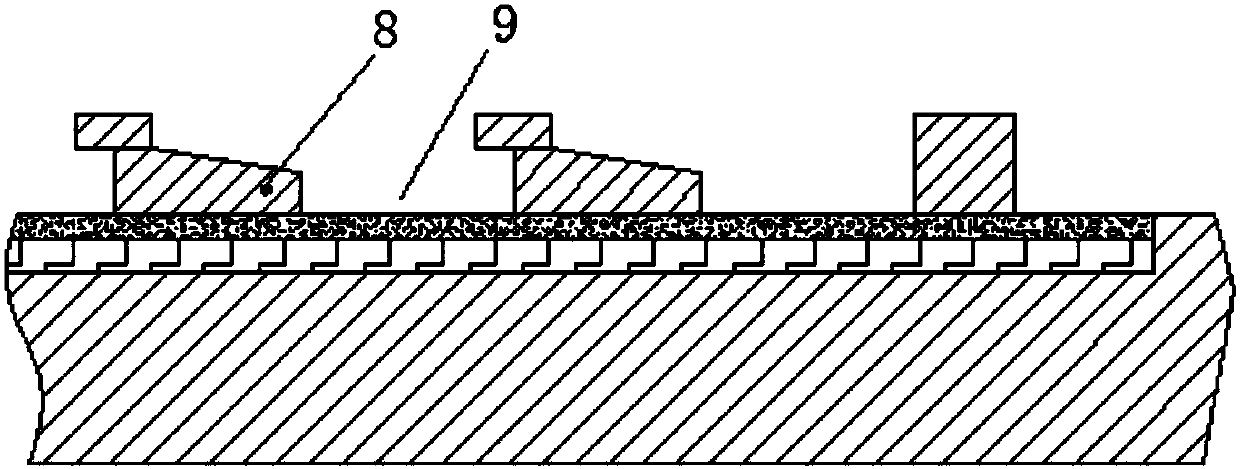

[0027] Such as Figure 1 to Figure 7The surface structure of the coarse sand shaker surface of the improved Yunxi-type shaker is shown. The shaker surface includes a rough selection area 1, a coarse multiple selection area 2, a first fine multiple selection area 3, and a second The second fine multiple selection area 4, the third fine multiple selection area 5, the shallow ditch area 6, and the fine selection area 7; the bottom slope of the shaker surface is composed of three variable slopes and three flat slopes starting from the rough multiple selection area, among which the rough multiple selection area 2 is the first climbing pinch-out area, the first fine multi-selection area 3 is a flat slope area, the second fine multi-selection area 4 is the second climbing pinch-out area, and the third fine multi-selection area 5 is the third climbing shallow pinch-out area The ditch area, the shallow ditch area 6 is a triangular plane area, and the selected area 7 is also a triangula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com