Process for increasing complicated sulfurized-lead-zinc ore dressing recovery rate

A technology of sulfide ore, lead and zinc, applied in the field of green technology, can solve the problems of increasing collector consumption, increasing production cost, increasing environmental pollution, etc., and achieving obvious economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The ore properties of the present embodiment 1 are: lead-zinc sulfide ore raw ore multi-element content (wt%): Pb 5.6, Zn6.61, S 21.27, Fe 16.97, Cu 0.02, As 0.33, Ca 3.49, Mg 0.49, SiO 2 18.6, Al 0.74, Ag 63.3g / t, Au 0.7g / t. Oxidation rate of ore is Pb5.75%, Zn6.99%. The main metal minerals in the ore are galena, sphalerite, pyrite, pyrrhotite, and a small amount of pyrotite, marcasite, chalcopyrite, arsenopyrite, chalcocite, copper blue, Tetrahedrite, limonite and argentite, natural silver and silver-gold ore; gangue minerals are mainly quartz, chlorite, sericite, calcite, and a small amount of gypsum, dolomite, siderite, muscovite and Clay minerals.

Embodiment 1

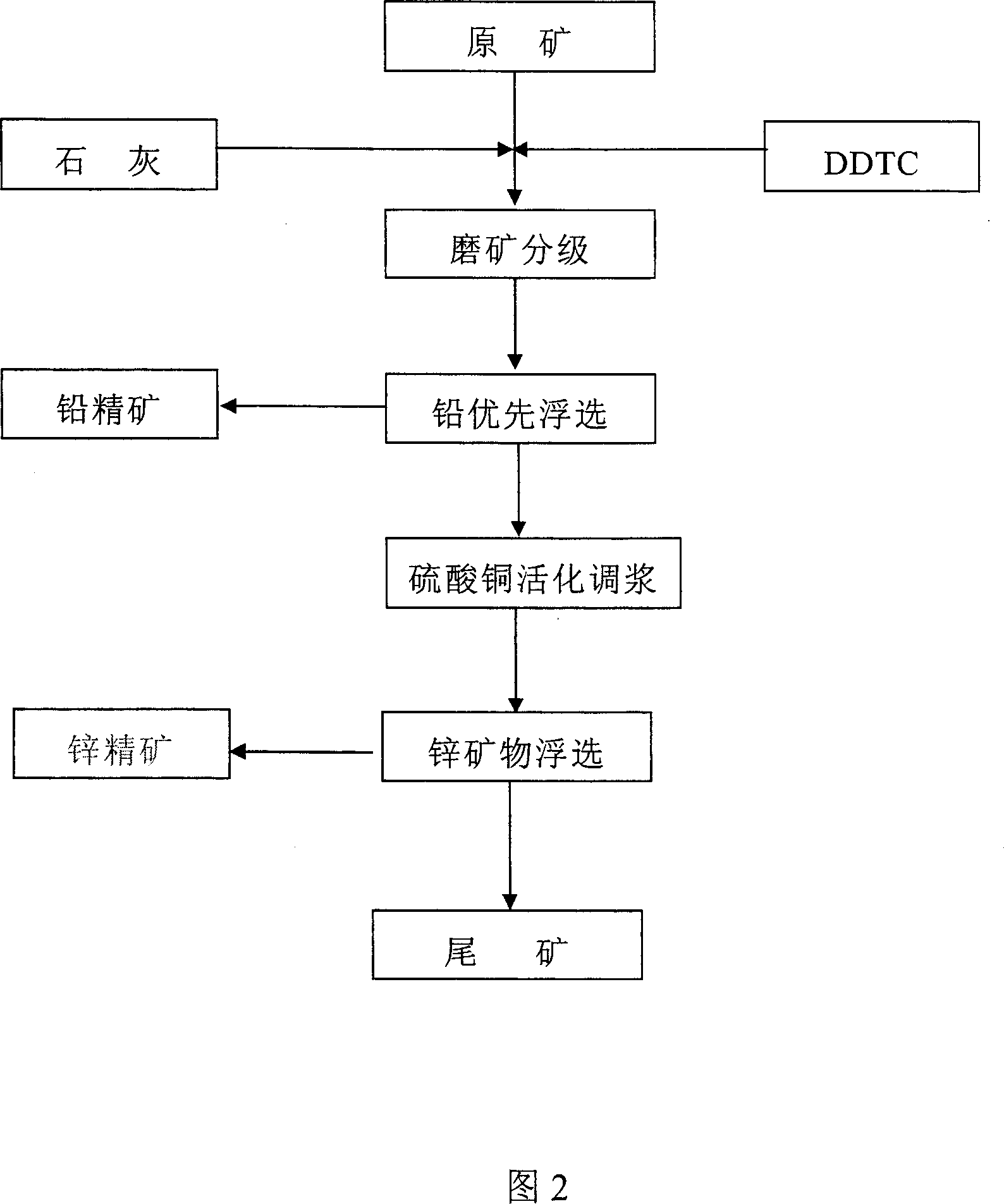

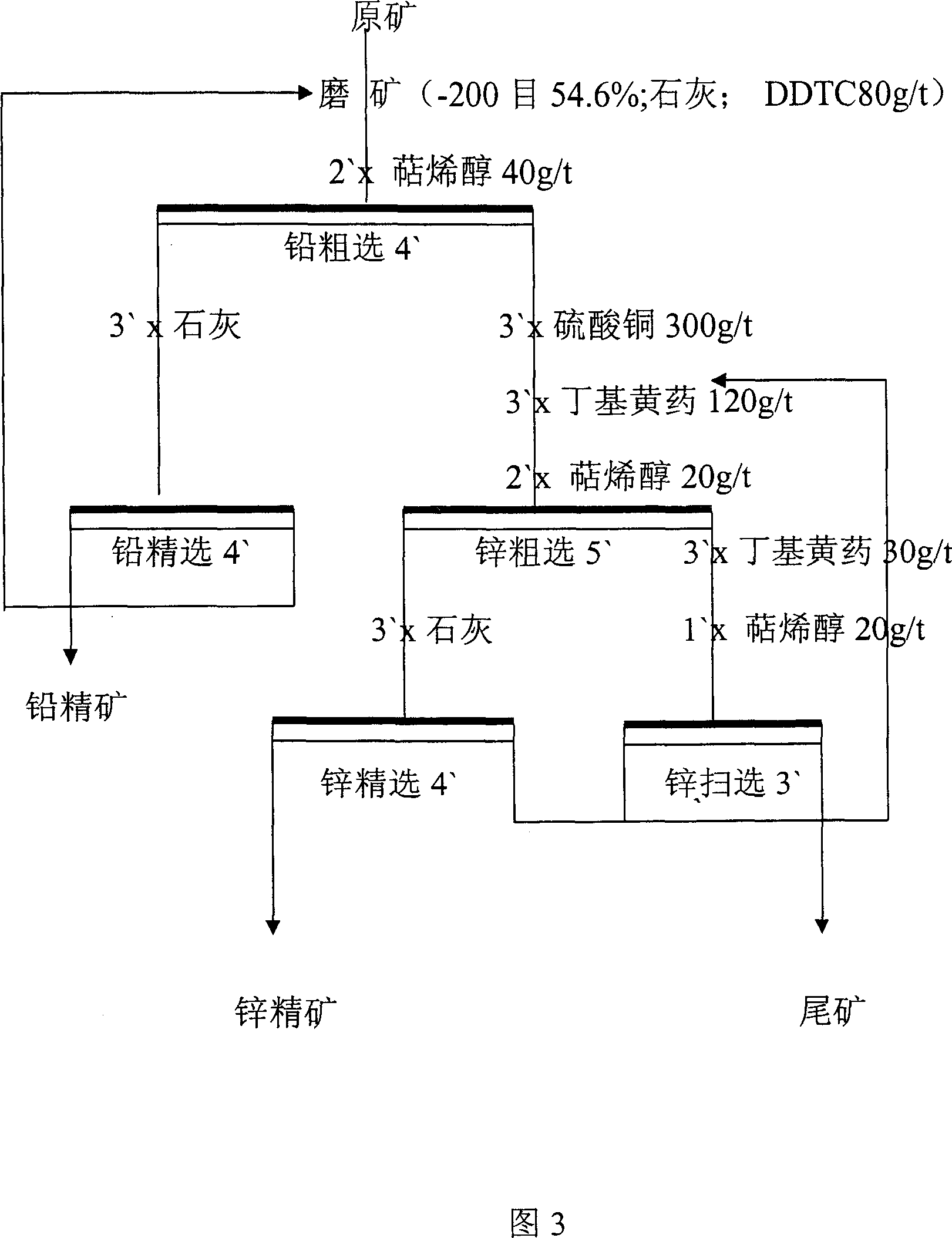

[0044] The technical process conditions for implementing Example 1 are: pulp pH 12.8, pulp potential -255mv, sorting process flow and medicament system as shown in Figure 3.

[0045] The comprehensive closed-circuit results of the laboratory of Example 1 are shown in Table 1.

[0046]

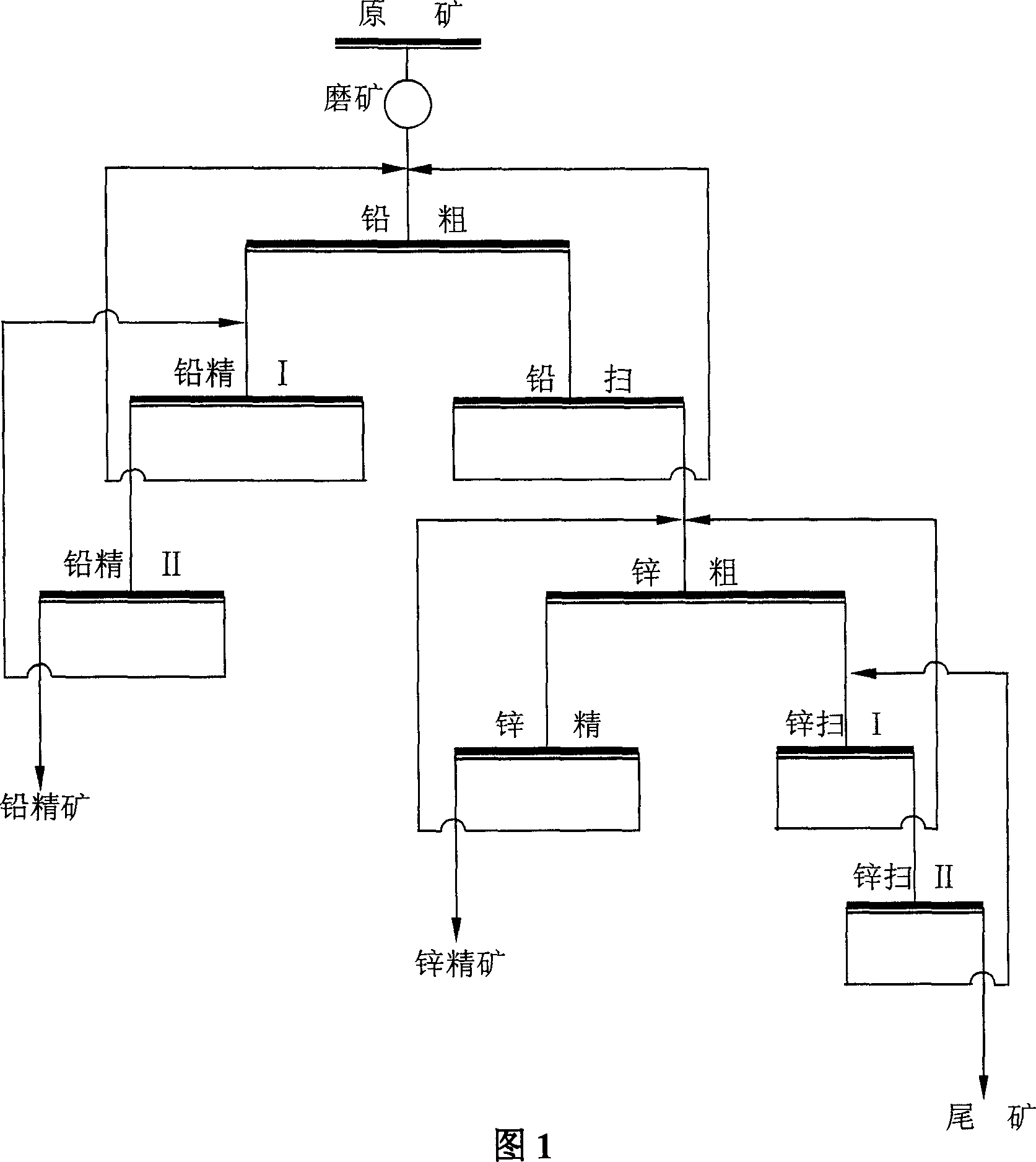

[0047] The test obtained lead concentrate contains Pb73.94%, Ag860.6g / t, lead and silver recoveries are 95.56% and 88.68%, zinc concentrate contains Zn51.65%, zinc recovery rate is 93.54%. Compared with the average index of the original process, the lead flotation recovery rate increased by 2.18 percentage points, the zinc concentrate grade increased by 2.25 percentage points, and the zinc recovery rate increased by 3.99 percentage points. The flotation process is simplified to only one lead roughing and one lead refining, and zinc only has one roughing, one refining and one sweeping.

Embodiment 2

[0049] The ore properties and mineral composition of Example 2 are the same as those of Example 1. The raw ore grade is: Pb 4.36-4.62%, Zn 5.71-5.97%, oxidation rate Pb 12.42%, Zn 8.62%.

[0050] The technical process conditions of this embodiment 2 are: pulp pH 12.3, potential -320mv, pharmaceutical system: DDTC 33g / t, terpene alcohol 50g / t, copper sulfate 450g / t, butyl xanthate 100g / t. The selection process is shown in Figure 4. The industrial test results are shown in Table 2.

[0051]

[0052] Compared with the same period of last year, the lead recovery rate of the technical process of the present invention in embodiment 2 was 1.83 percentage points higher, the main grade of the lead concentrate was increased by 5.42 percentage points, the zinc recovery rate was increased by 2.39 percentage points, and the lead-zinc concentrate mutual content was further reduced. The dosage of flotation agents is reduced by more than two-thirds of the lead collector, copper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com