Self-adaptive flotation foam de-foaming device and de-foaming method

A self-adaptive, defoaming device technology, applied in the direction of foam dispersion/prevention, can solve the problems of difficult to advance the production process, slow defoaming speed of defoamer, and inability to eliminate foam in time, so as to achieve strong equipment adaptability and improve Defoaming efficiency, overcoming the effect of continuous water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

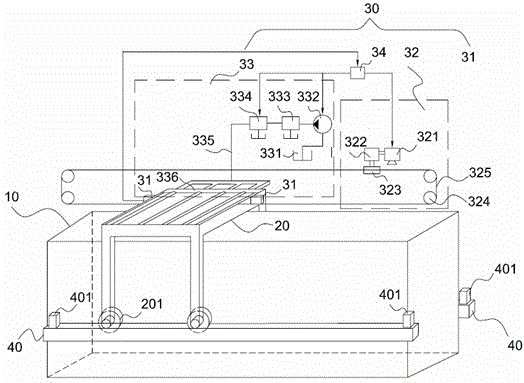

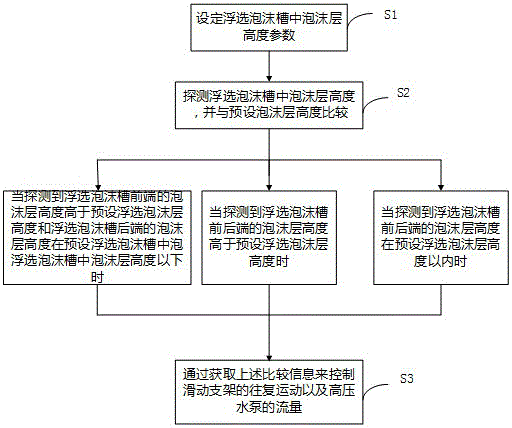

[0036] refer to figure 1 As shown, the embodiment of the present invention provides an adaptive flotation foam defoaming device, including a flotation foam tank 10, a sliding support 20 arranged on the flotation foam tank 10, and used to control the sliding support 20 in the An adaptive control defoaming system 30 for reciprocating motion on the flotation foam tank 10 . In this embodiment, the flotation foam tank 10 is a box, and the foam tank of the existing flotation equipment can be used. Since the flotation material is brought into the foam tank 1 by the foam, the flotation foam tank 1 plays a role in collecting The important role of flotation. The sliding bracket 20 supports the high-pressure spray head, and under the control of the adaptive control defoaming system 30, it can reciprocate along the flotation foam tank 10 and the high-pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com