New method for detecting internal defect of honeycomb

A technology of internal defects and new methods, applied in measuring devices, material analysis using wave/particle radiation, solid analysis using sonic/ultrasonic/infrasonic waves, etc., can solve the problem that the location and nature of defects in honeycomb structural parts cannot be determined, and the detection methods are unfavorable. Defect characterization, positioning and quantification, increasing the working time of inspectors, etc., to avoid image overlap and blur, facilitate observation, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

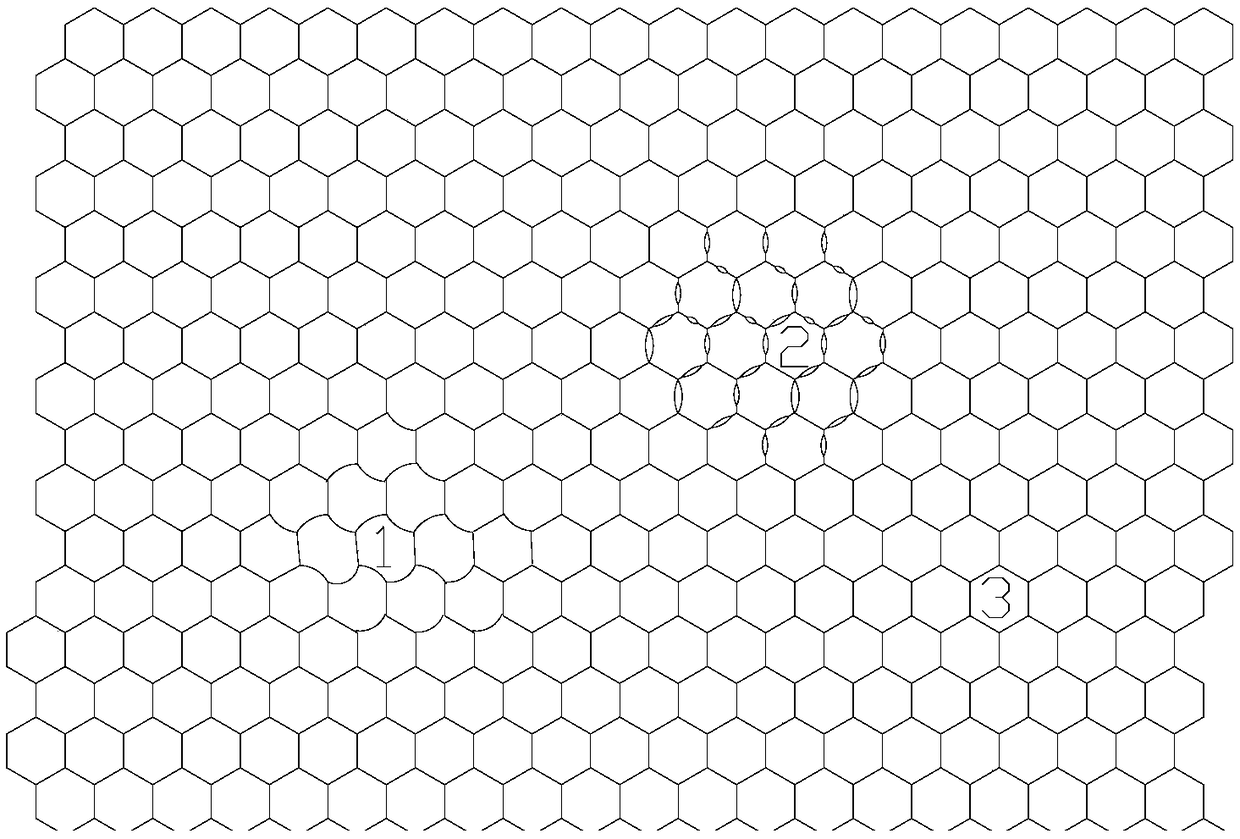

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0023] A new method for detecting defects inside a honeycomb, the steps are as follows:

[0024] Step 1: Use the ultrasonic scanning technology of the water jet penetration method to conduct a comprehensive inspection of the honeycomb sandwich structure parts, and use the comparison test block to adjust the sensitivity so that the instrument can detect the defects between the parts skin, glue joint and honeycomb core; then adjust the water The distance, scanning speed and scanning step are used to detect the defects between the skin, glue joint and honeycomb core of the parts again, and mark the defect indicating part in the detection result as position A;

[0025] Step 2: Use the reflection ultrasonic scanning technology to detect the defect at A, and use the comparison test block to adjust the sensitivity so that the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com